Semiconductor laser with integral spatial mode filter

a technology of spatial mode filter and semiconductor laser, which is applied in the field of external cavity semiconductor lasers, can solve the problems of mw cw, associated higher output power, and generally low output power, and achieve the effect of high power amplification of forward propagating ligh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

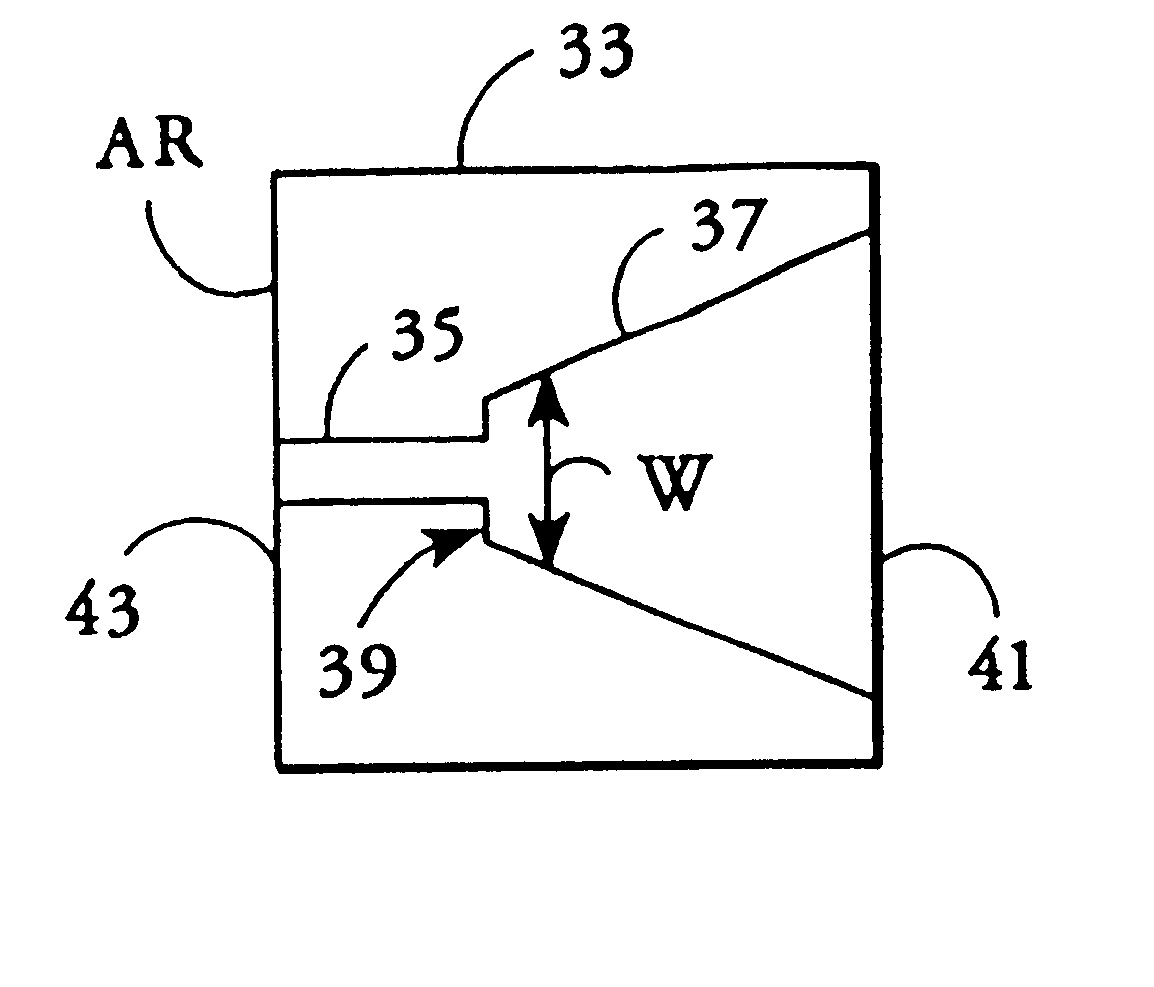

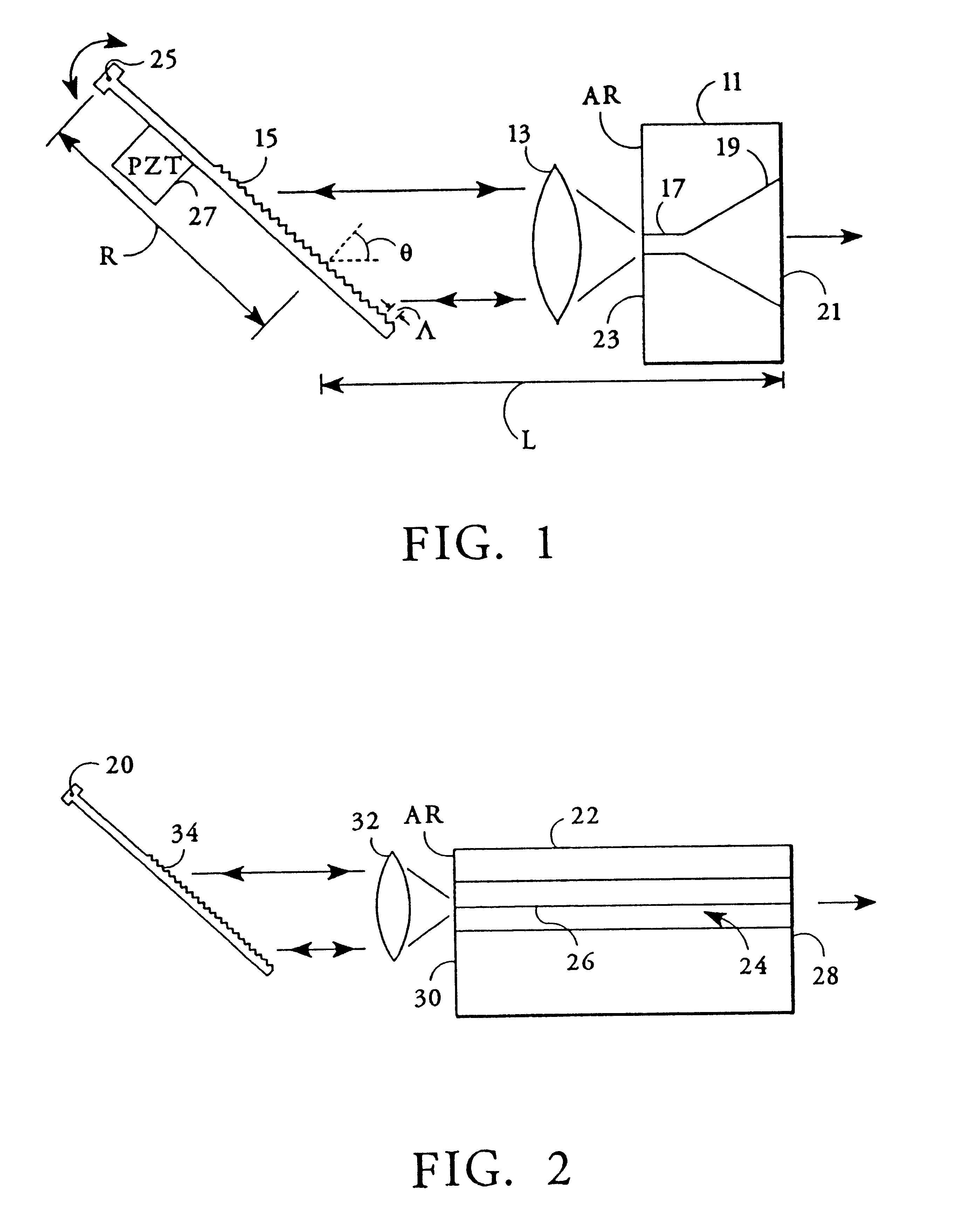

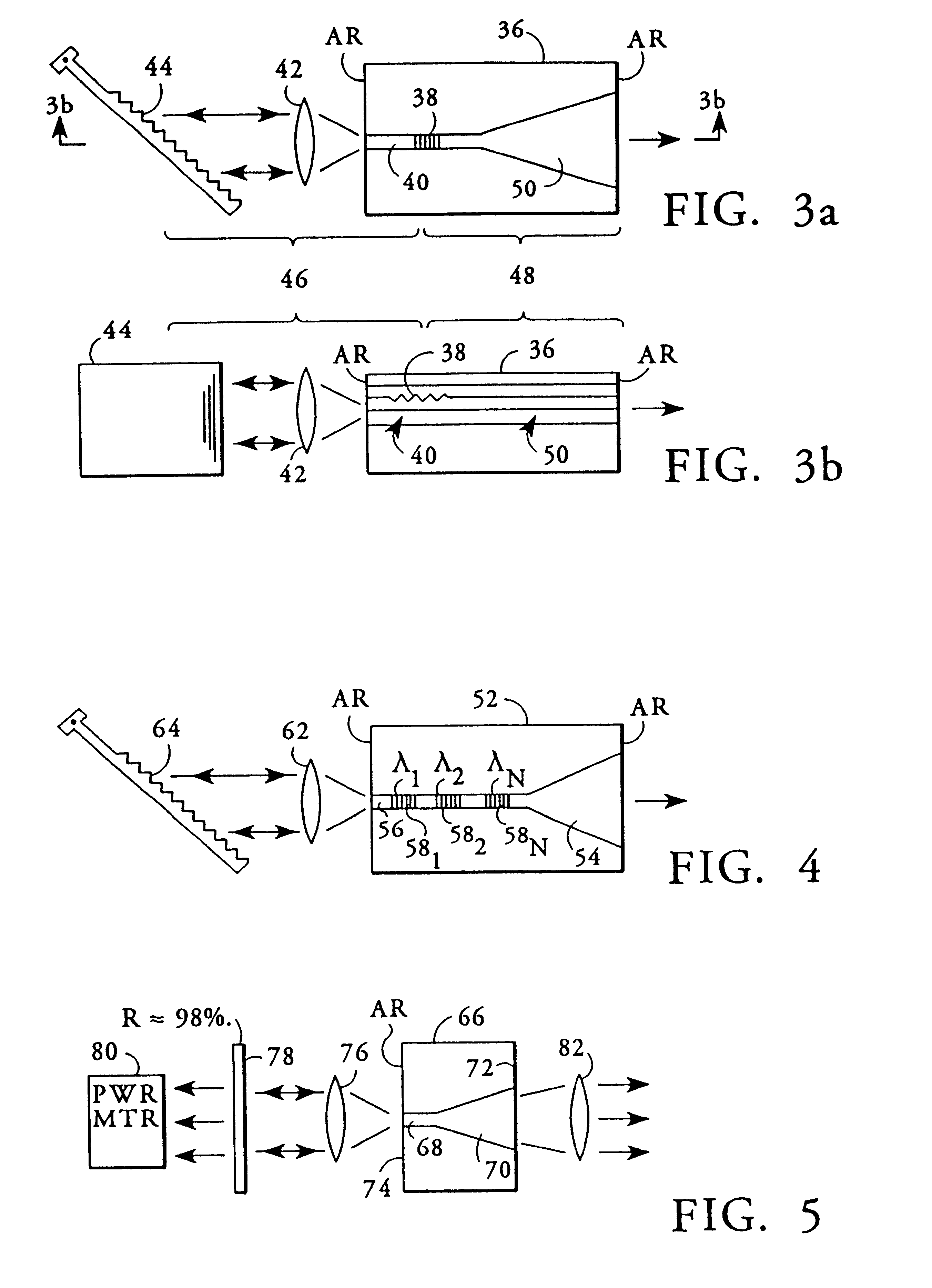

With reference to FIG. 1, an external-cavity semiconductor laser, in accord with one embodiment of the present invention, has an active gain medium that is a light amplifying diode heterostructure or "amplifier chip" 11, and also has a light reflective, external, diffraction grating 15 and a lens 13. The amplifier chip 11 shown in FIG. 1 has a single mode waveguide section 17 incorporated on the grating side of the chip, opening into a flared gain section 19 on the output side of the chip. Preferably, the flared gain region 19 is linearly flared and increases in width toward the front output facet 21 of the amplifier chip 11 at a rate that is slightly greater than the divergence of light propagating within the flared gain region 19. The front output facet 21 is typically coated for low reflection. Though a facet reflectivity of 30% would likely be acceptable, typically the reflectivity of the coated facet 21 is less than 10%, with a 2 to 3% reflectivity being preferred. The rear fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com