Additive for, method of adding thereof and resulting cured cement-type concreations for improved heat and freeze-thaw durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

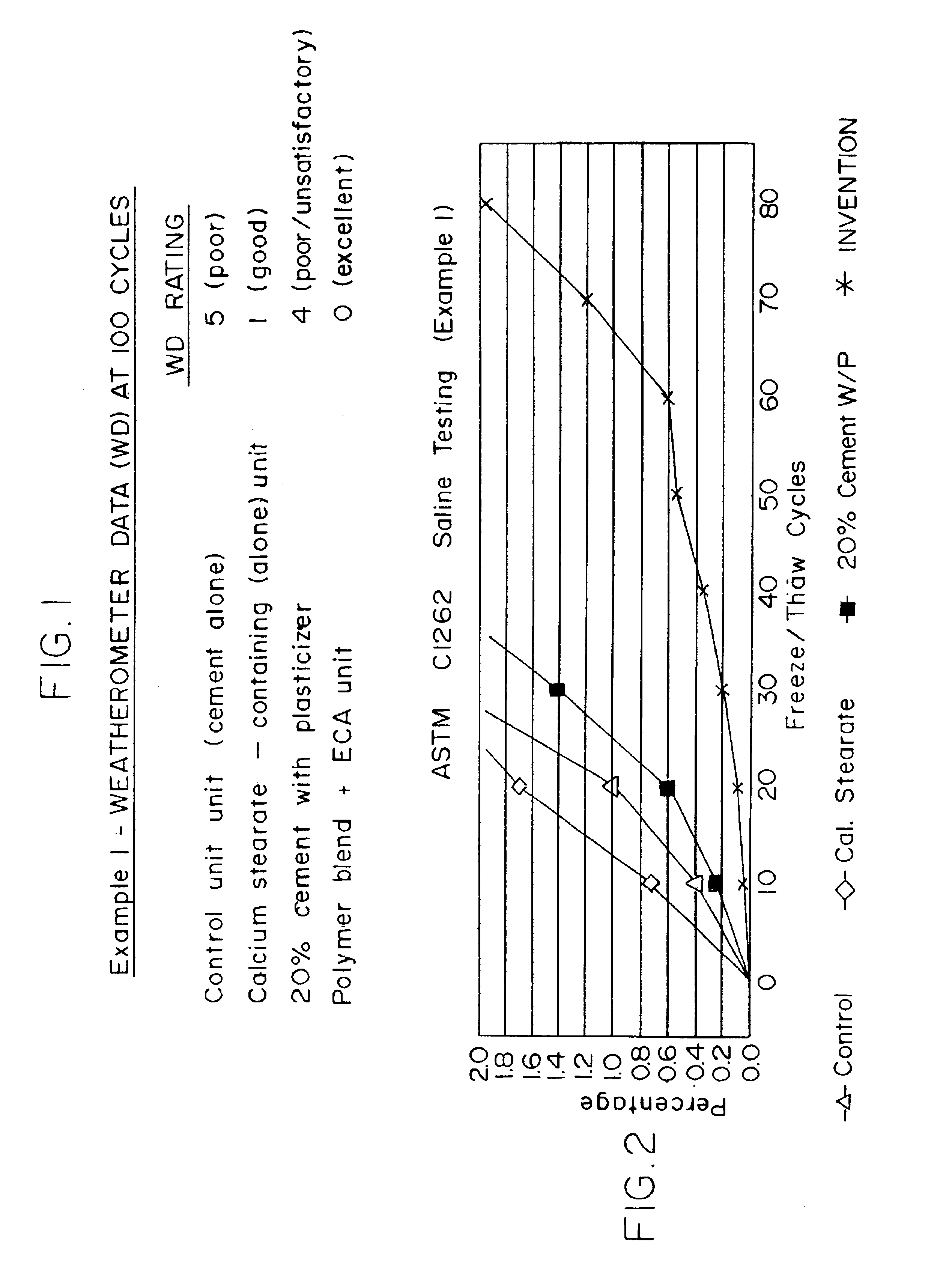

This example is directed to a composition and procedure relating to durability of a concrete segmental retaining wall unit.

To a laboratory batching kitchen aid mixer, 150 grams, of normal type 1 cement was added. In addition, 1350 grams of stone and sand fitted to any optimized aggregate blend curve for a typical retaining wall with an FM of 3.70 was added. In addition, a red iron oxide pigment was added at 3.0% based on the weight of cement (4.5 grams). The cement, aggregate and pigment were blended for two minutes. Sixty grams of water was added sufficient to attain a water to cement ratio of 0.40. The material was then blended for an additional 90 seconds. At that point, 2.45 grams (25 ounces per hundred weight of cement equivalent) of the efflorescence control agent and polymer blend were added to the mix. The efflorescence control agent(s) (ECA) represents 35% by weight and the polymer blend represents 65% by weight. The ECA was a modified calcium stearate. The polymer blend in...

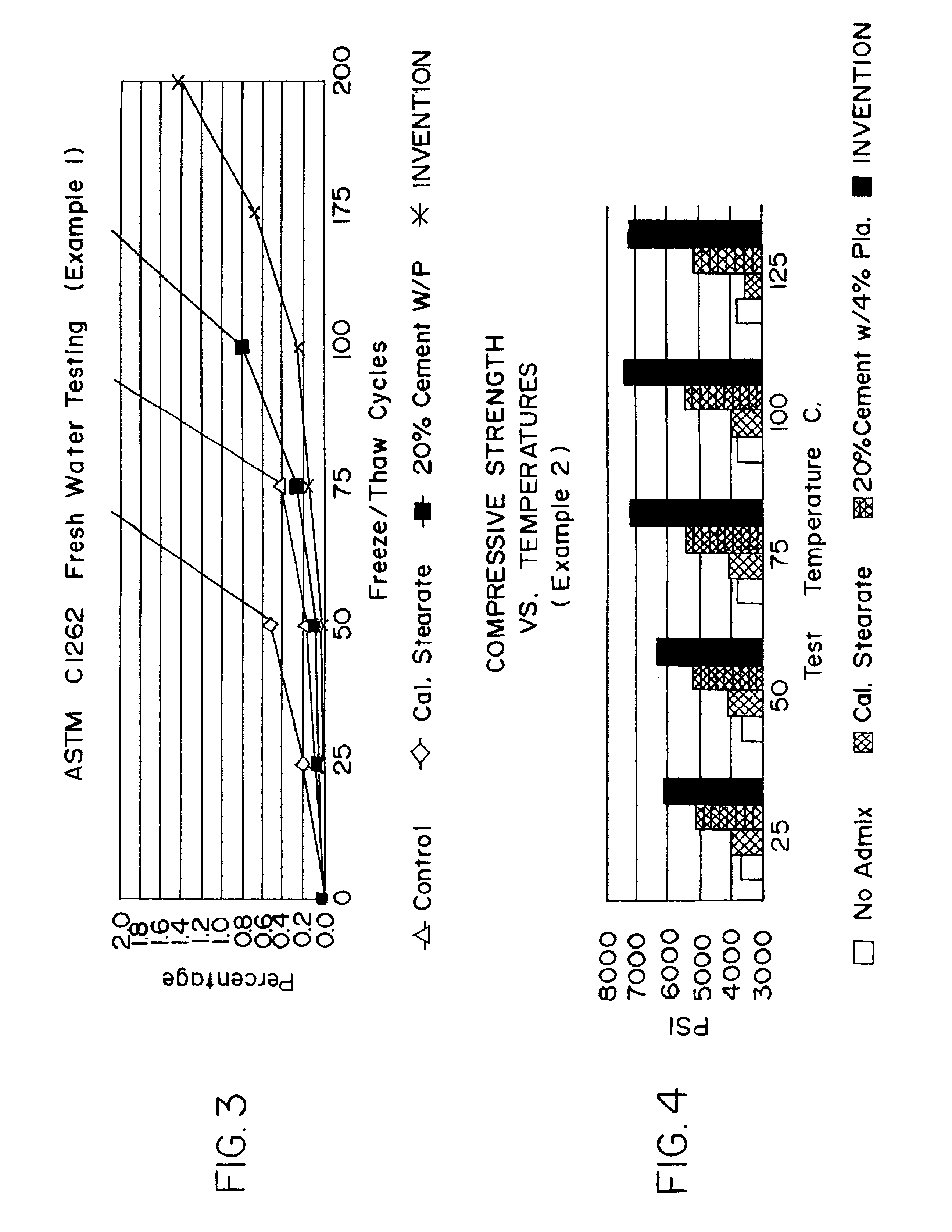

example 2

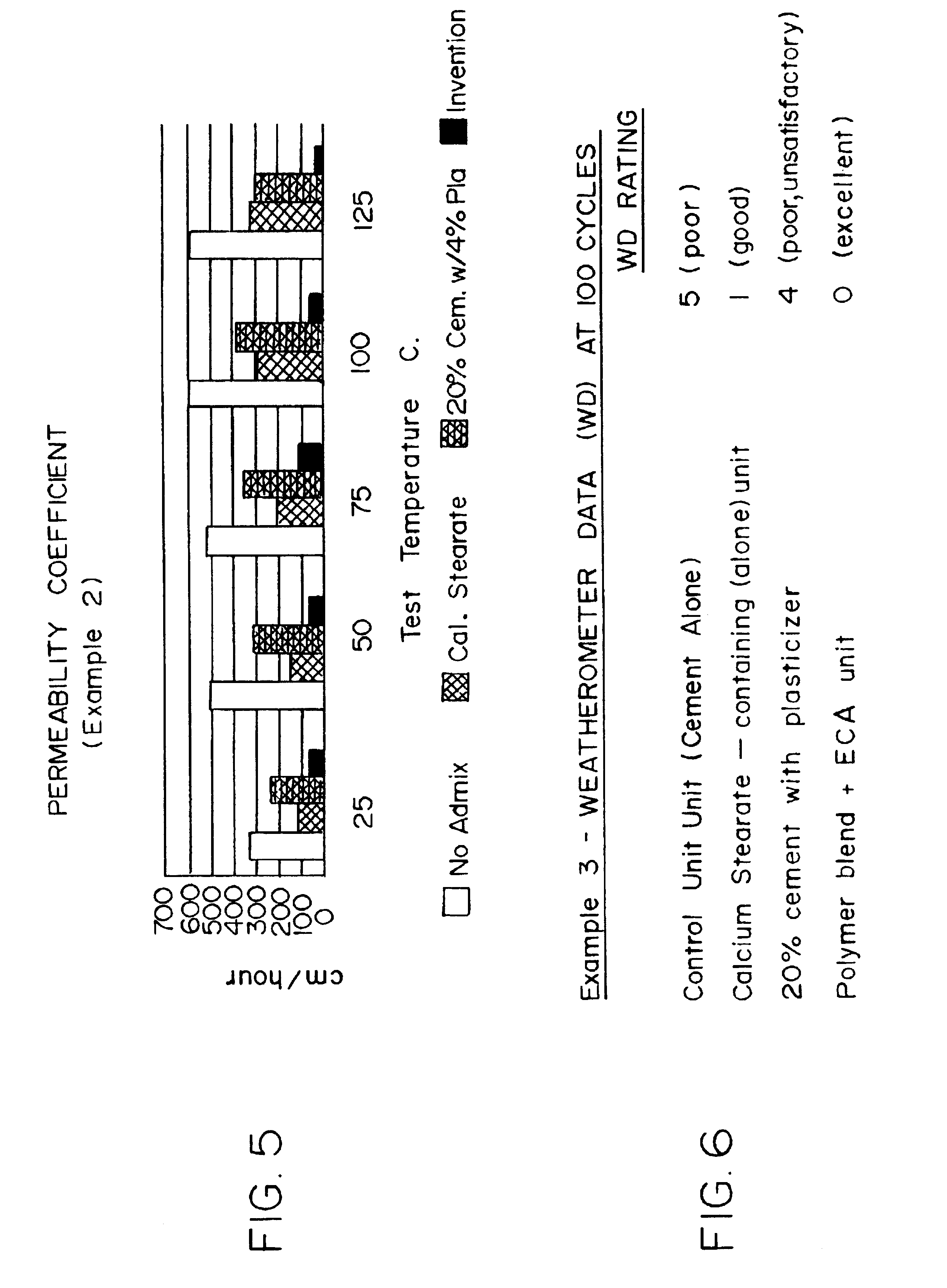

For the same categories as aforenoted example, comparing compressive strength (as psi) versus different temperatures in a series of different comparisons, FIG. 4 likewise exhibits marked superior performances as regards compressive strength for each comparison. FIG. 5 likewise exhibits marked superior performance in permeability, as regards centimeter(s) (cm) per hour for each comparison.

example 3

For the same categories as aforenoted Example 1, but here on a full scale basis for a production series of units manufactured in an Allen Block Segmental Retaining Wall style, the illustrated results of FIGS. 6, 7 and 8 confirm tests comparable to Example 1 and FIGS. 1 through 3, confirming marked superiority in all categories.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com