Flexible stent having a pattern formed from a sheet of material

a flexible stent and pattern technology, applied in the field of balloon expandable stents, can solve the problems of stress points formed at each wire bend or turn, affecting the longitudinal stability of bent wire stents, so as to prevent longitudinal contraction or expansion of stents, minimize the thickness of stents, and prevent the effect of longitudinal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

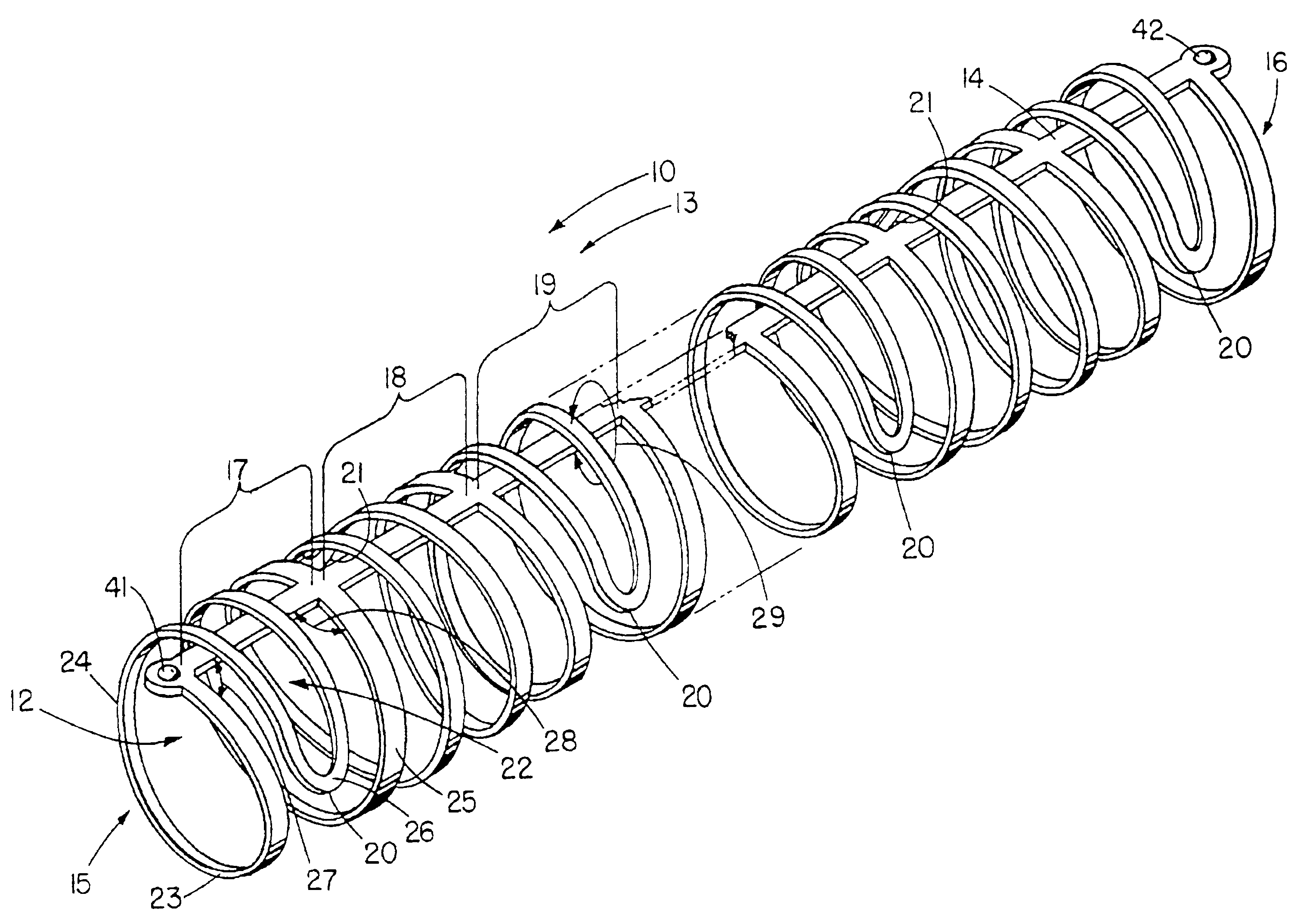

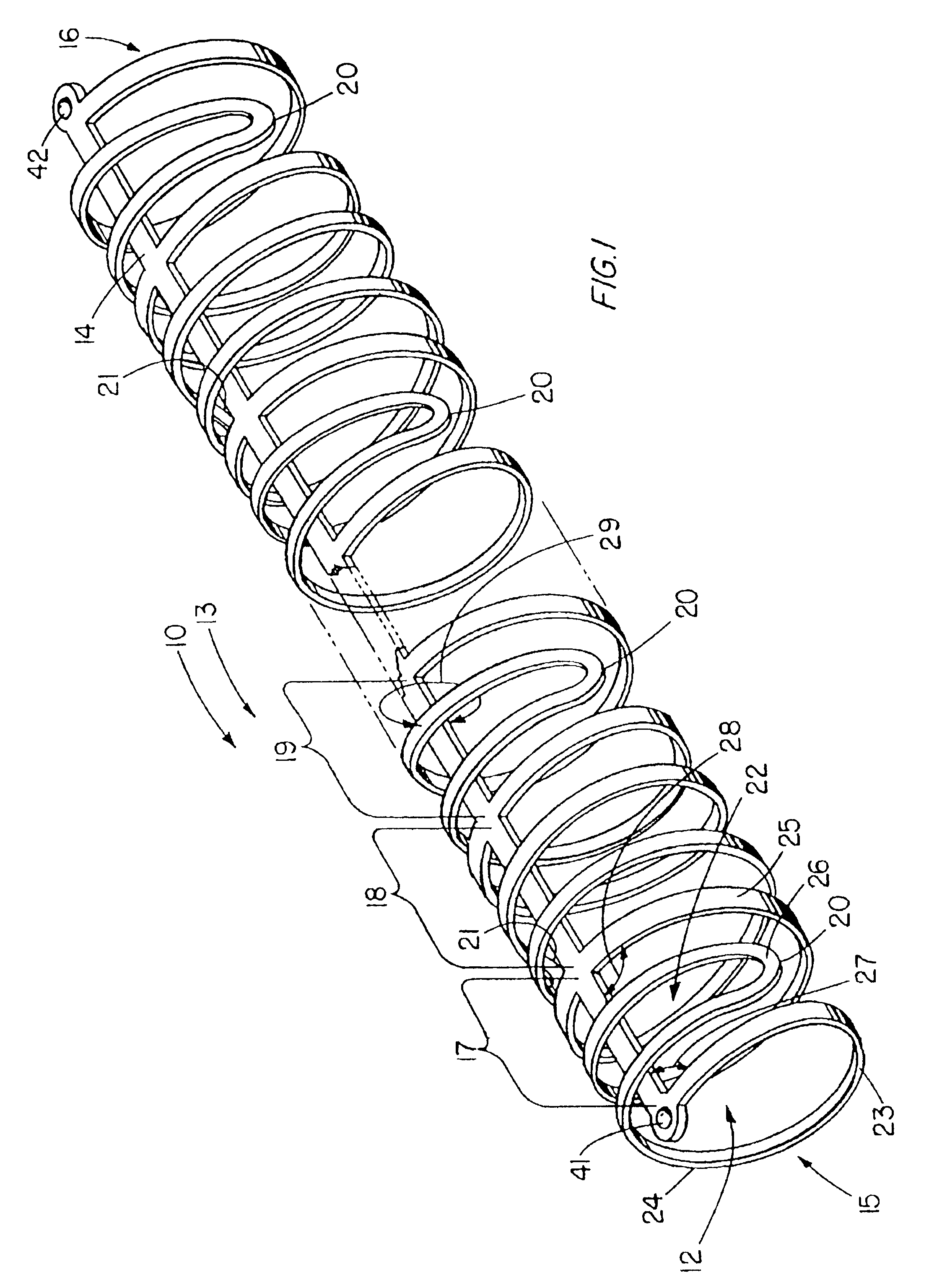

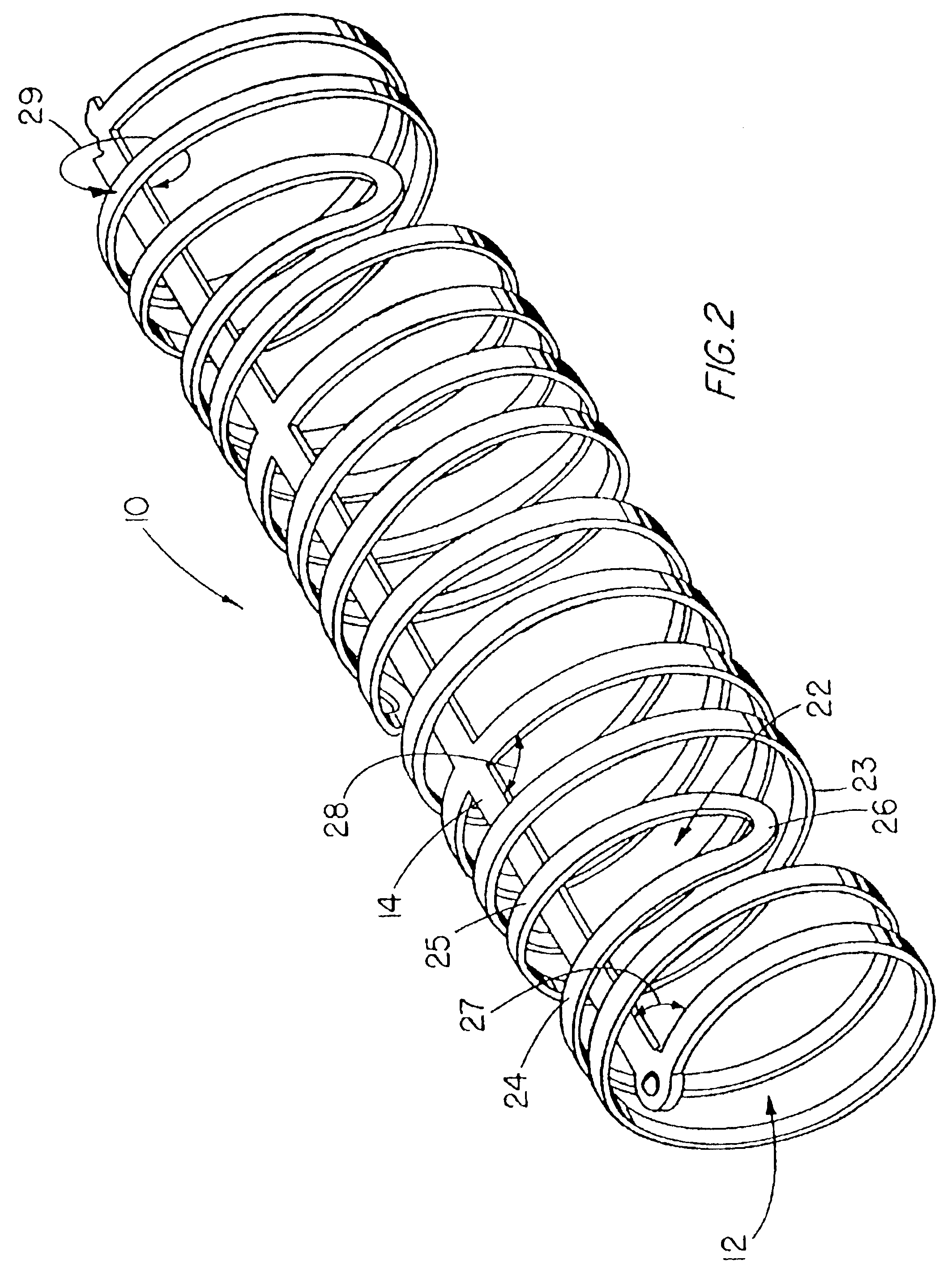

[0027]FIG. 1 depicts a pictorial view of a preferred illustrative embodiment of unmounted flexible stent 10 in an overlapping state and comprising a waveform pattern 13 formed from a flat sheet of biocompatible material and into a tubular shape 12. The tubular shaped pattern is expanded with a delivery catheter balloon in a body passage such as a blood vessel to maintain an open lumen therethrough. As depicted in FIG. 9, pattern 13 is formed from a flat sheet 11 of malleable, biocompatible material such as stainless steel by, for example, photochemically removing a majority of the sheet material and leaving a framework of integrated support members that has a small surface area relative to the initial surface area of the sheet. After formation from the sheet, the pattern is formed into a partially cylindrical or U-shaped surface around a cylindrical mandrel and then positioned in the overlapping state around a deflated, delivery catheter balloon and into tubular shape 12.

[0028]Patte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com