Method and apparatus for extrusion of expanding water holding products such as foodstuff particles or feeding stuff pellets

a technology of expanding water holding products and extrusion methods, which is applied in the direction of food preservation, baking, animal feeding stuff, etc., can solve the problems of difficult to ensure, difficult to predict the variation of production, and the great problems of all extrusion systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

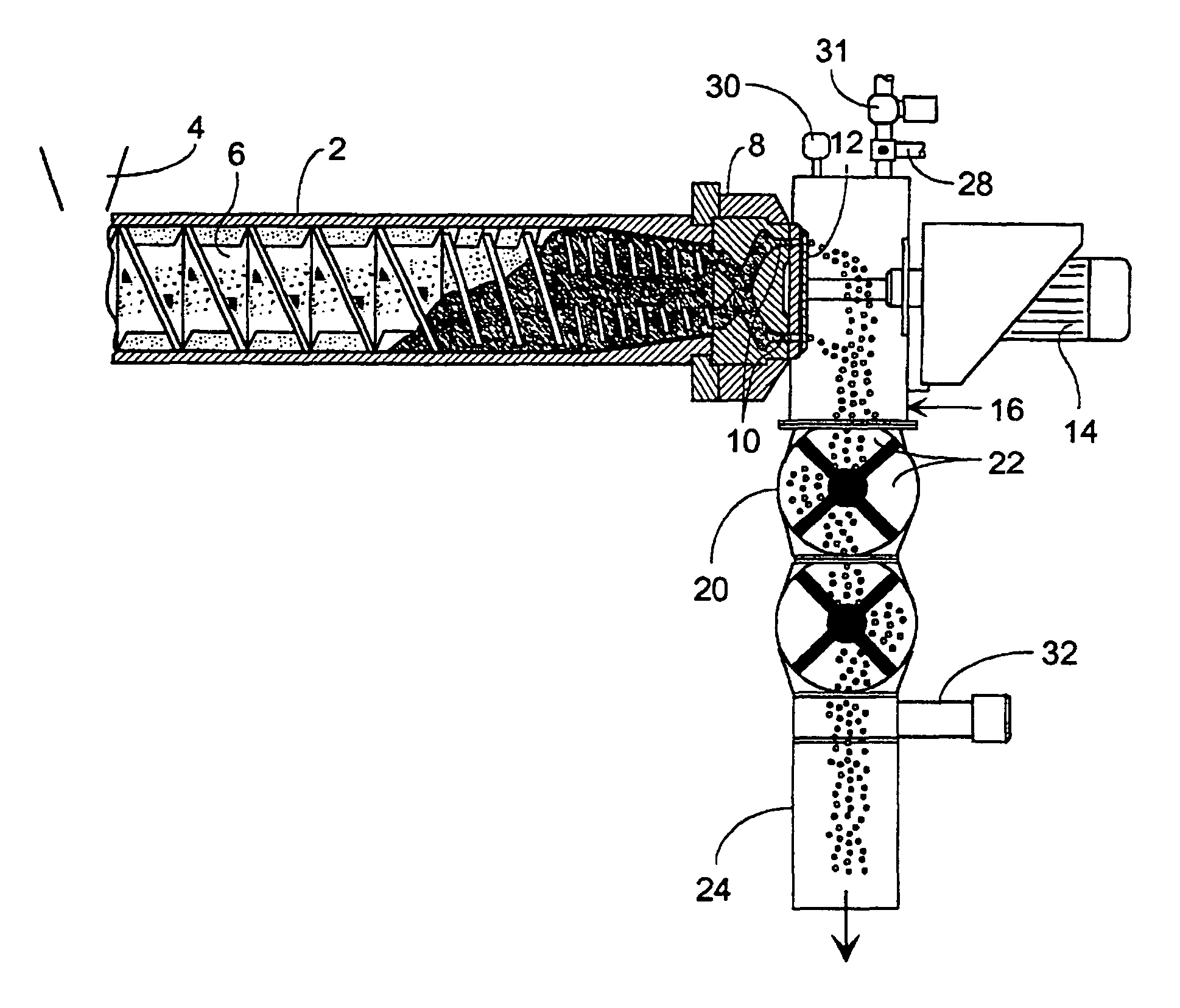

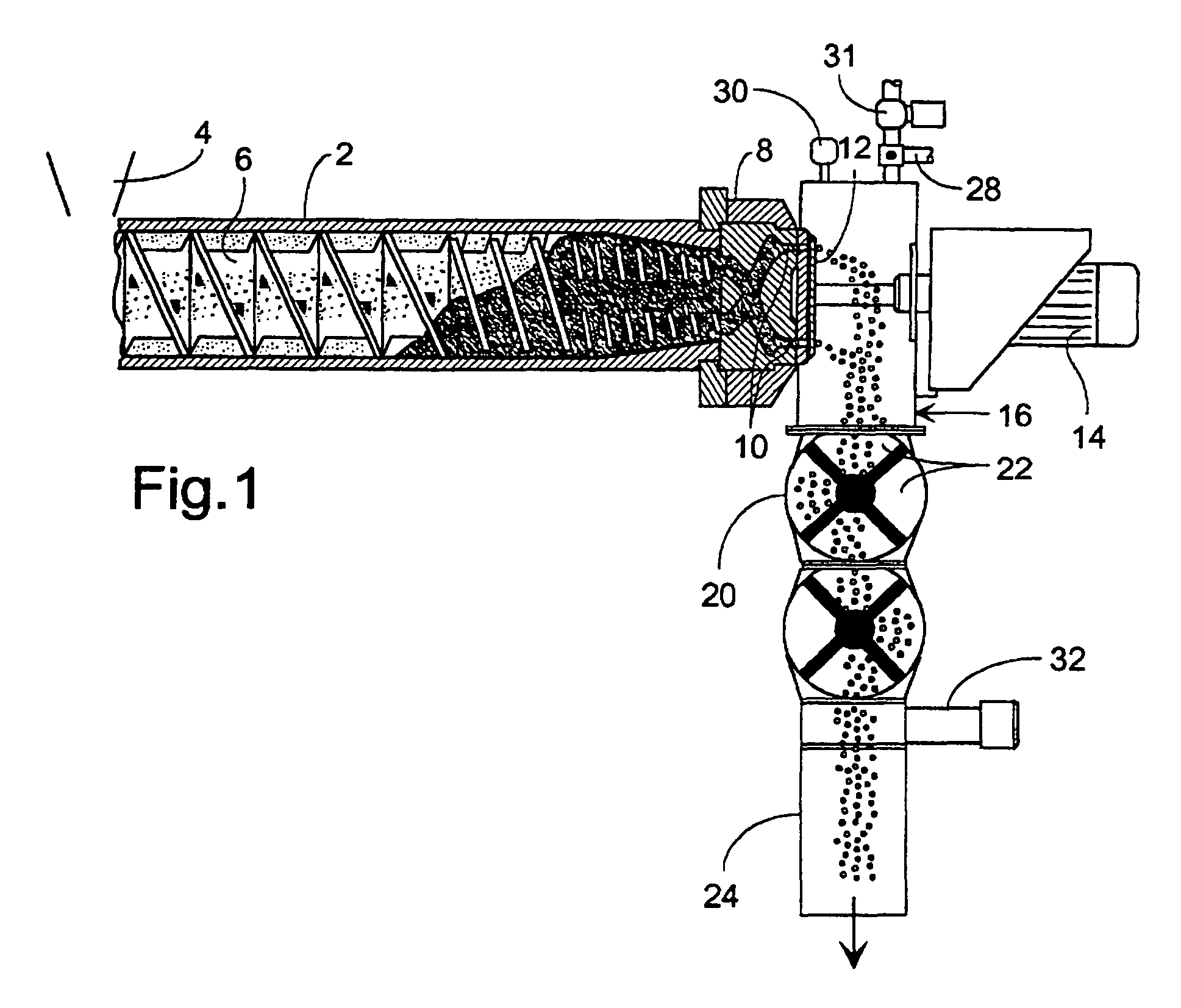

[0032]To the left is shown an extruder2 with a supply funnel or conduit for the material which is to be formed into the desired granular product, and with an extruder worm 6 for transporting the material forward towards a nozzle unit 8 with nozzle channels 10 through which the material is pressed out in string form. In quite the same way as a meat mincer, in front of the nozzle unit 8 there is provided a rotating knife 12 which is driven by a motor 14, the result being that said strings are continuously cut over in the formation of pellets which can simply fall down into a suitable collection or transport arrangement.

[0033]In accordance with the invention, opposite the delivery end of the nozzle unit 8 there is a box element 16 which is connected with the edge of the nozzle unit in a tight-fitting manner, and which also has a tight-fitting sleeve 18 for the drive shaft of the motor 14. The box element 16 has a bottom part in the form of a rotating sluice wheel 20 with sluice pockets...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com