Patents

Literature

31results about How to "Lifting self-convection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic matter anaerobic fermentation processing method based on circulation stirring

InactiveCN105907623AEvenly distributedAvoid breakingBioreactor/fermenter combinationsBiological substance pretreatmentsOrganic matterBiology

The invention discloses an organic matter anaerobic fermentation processing method based on circulation stirring. Before fermentation raw materials are placed in, a circulation flow hole is covered with a flow blocking plate so as to block convection of a feed inlet and a discharge outlet, then, fermentation raw materials are poured into the feed inlet, a stirring rod is pulled to promote the fermentation raw materials to deeply enter a fermentation cavity in the direction from the feed inlet to the discharge outlet, and uniform distribution of the fermentation raw materials is promoted; the fermentation raw materials are poured into the feed inlet, the stirring rod is pulled to carry out stirring in the direction from the feed inlet to the discharge outlet in a turbulence area, and uniform distribution of the fermentation raw materials in the fermentation cavity is promoted.

Owner:李俊

Microbial fermentation treatment method of industrial organic waste

InactiveCN105950448AAvoid breakingAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industryConvection

The invention discloses a microbial fermentation treatment method of industrial organic waste. The method comprises the following steps of a feeding process: before fermentation raw materials are put, a flow blocking plate covers a circulation flowing hole through operating a traction rod so that the convection between a feeding opening and a discharging opening is blocked; then, the fermentation raw materials are poured into the feeding opening; the stirring is performed in the direction from the feeding opening to the discharging opening in a spoiler interval through pulling a stirring rod; the fermentation raw materials are promoted to go deep into a fermentation system; the uniform distribution of the fermentation raw materials are promoted.

Owner:方华椿

Method for preparing new energy from plant straw through anaerobic fermentation

InactiveCN105907799AIncrease the maximum capacityAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasProcess engineering

The invention discloses a method for preparing new energy from plant straw through anaerobic fermentation. The method comprises the steps that gas is guided, wherein a gas guide device is utilized for guiding out marsh gas in a gas storage plate, the gas pressure of the marsh gas in the gas storage plate is reduced, biogas slurry stored in a hydraulic pressure room flows back and flows into a feed inlet through a feed inlet drainage pipe in one way, and biogas slurry rich in strain is brought into the feed inlet; a material opening separation plate is opened for promoting bacteria distribution, wherein a circulation flowing hole is opened for achieving mutual convection of two ends, a stirring rod is utilized for stirring in a turbulence area, biogas residue precipitated near a discharge outlet is brought into the discharge outlet through movement in the direction from the feed inlet to the discharge outlet, biogas slurry rich in strain near the discharge outlet flows into the feed inlet through the circulation flowing hole, and uniform distribution of strains is promoted; in addition, a large amount of biogas residue can be taken out of the discharge outlet.

Owner:李俊

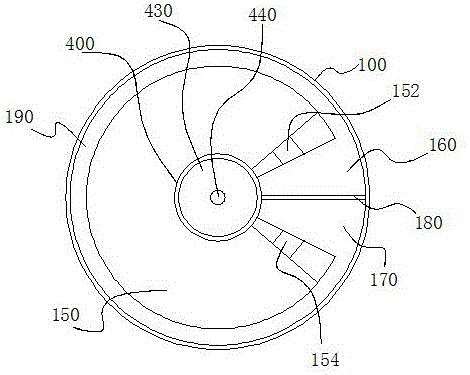

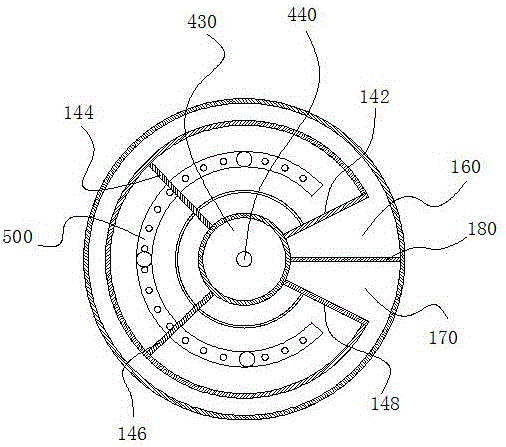

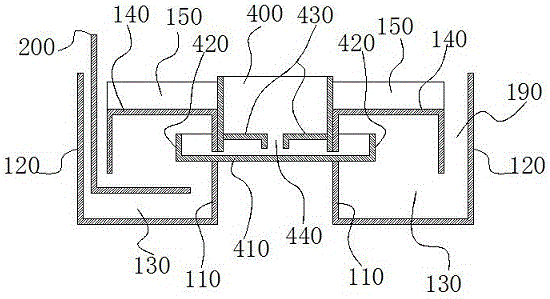

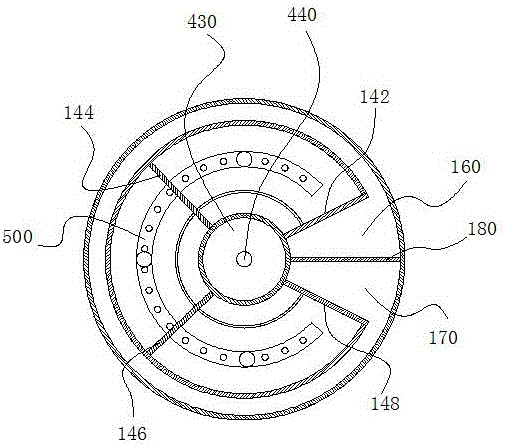

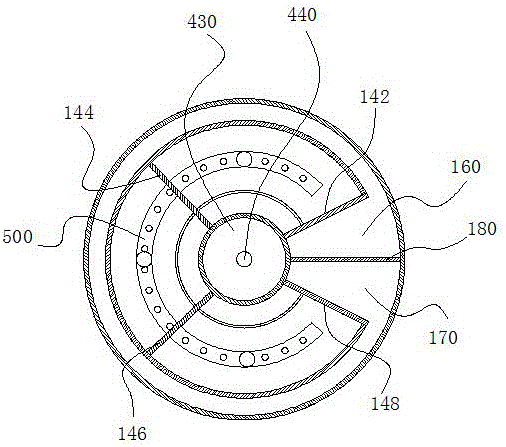

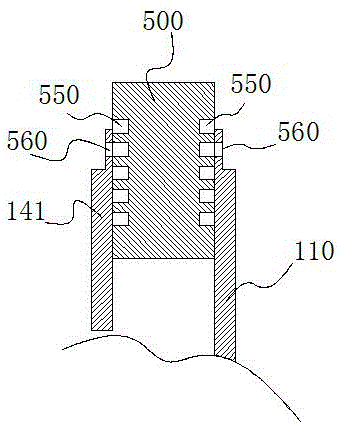

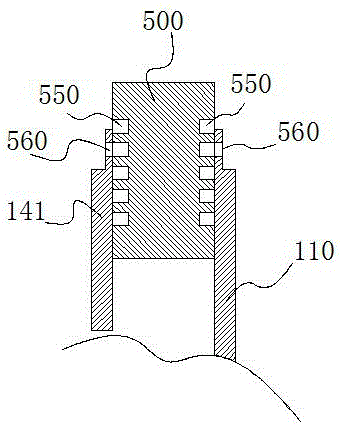

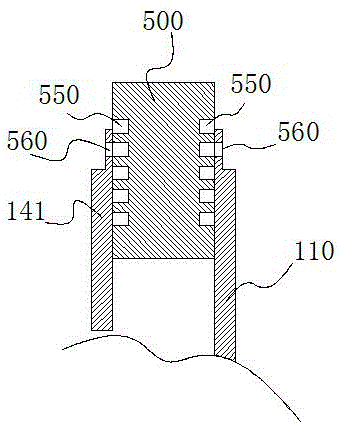

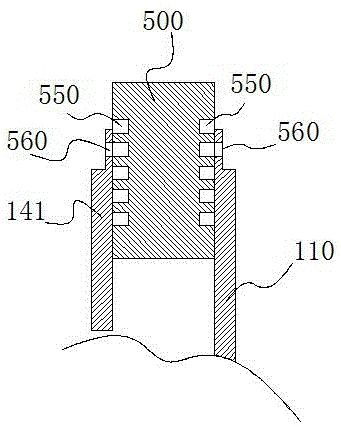

Microbial fermentation treatment system for domestic organic waste

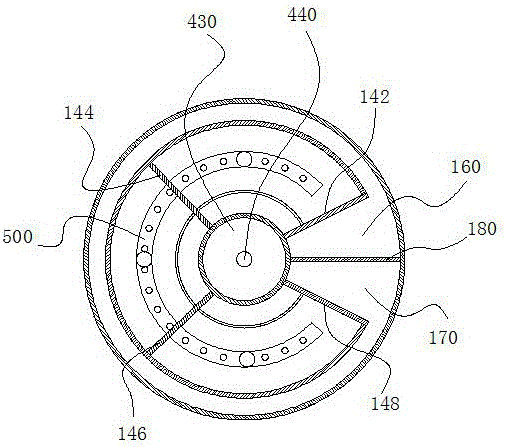

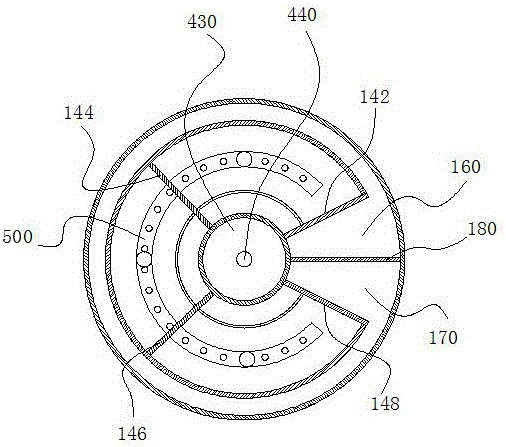

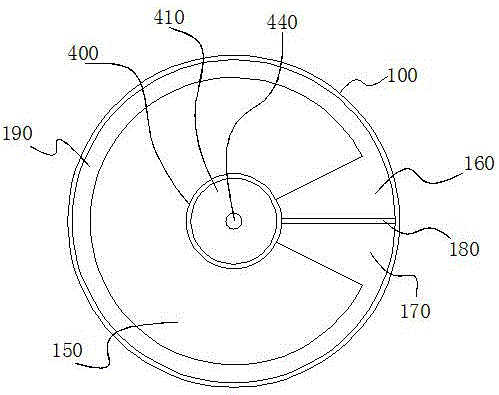

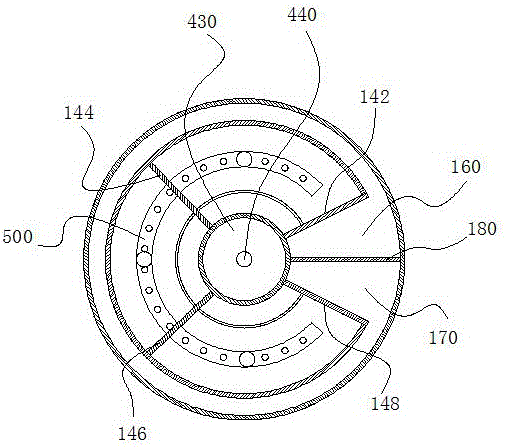

InactiveCN105950451AAvoid breakingAvoid blockingApparatus sterilizationGas production bioreactorsDraining tubeSlurry

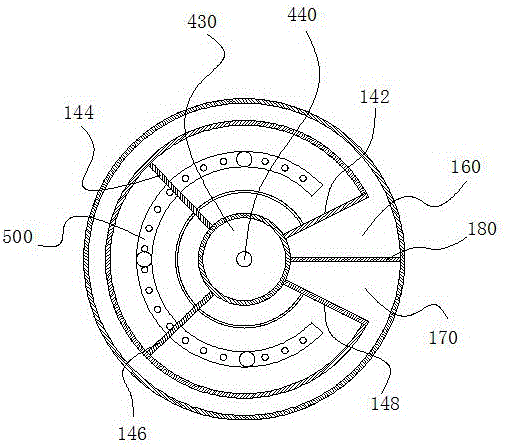

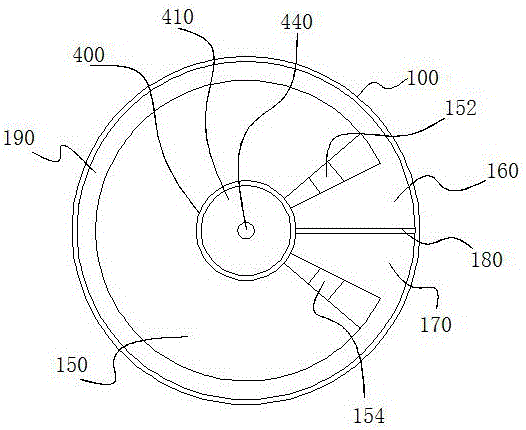

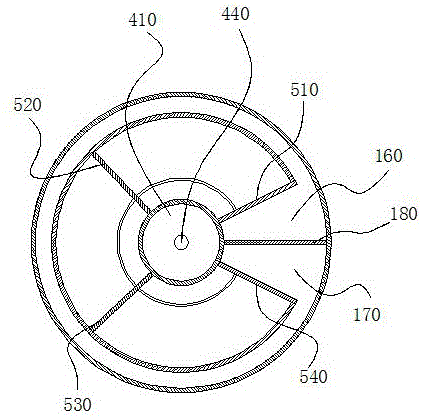

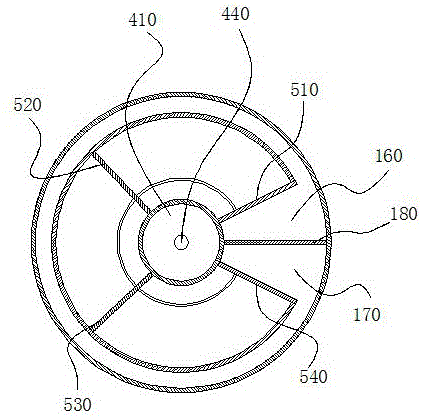

The invention discloses a microbial fermentation treatment system for domestic organic waste. The microbial fermentation treatment system comprises a fermentation tank body, a gas storage plate mounted in the fermentation tank body, a water pressure room mounted in the fermentation tank body and a sprue splitter plate for splitting the fermentation tank body, wherein the fermentation tank body is of a circular ring shaped structure; the top of a bacteria distribution pipeline is connected with the water pressure room; the bottom of the bacteria distribution pipeline is connected with a bacteria distribution pipeline which is distributed in a path direction of the fermentation chamber; a plurality of bacteria distribution holes which are through in a vertical direction are formed in the bacteria distribution pipeline; a one-way valve for controlling biogas slurry in the water pressure room to flow into a charge hole in a unidirectional manner is arranged on a water-draining tube of the charge hole; a one-way valve for controlling biogas slurry in a discharge hole to flow into the water pressure room in the unidirectional manner is formed in a water-draining tube of the discharge hole; a one-way valve for controlling the biogas slurry in the fermentation chamber to flow into the water pressure room in the unidirectional manner is arranged on the bacteria distribution device.

Owner:方华椿

Method for decomposing organic garbage by using microorganisms and preparing new energy

InactiveCN105886536AAvoid breakingAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismNew energy

The invention discloses a method for decomposing organic garbage by using microorganisms and preparing new energy. The method comprises the following steps: enabling fermentation raw materials to ferment inside a fermentation chamber; accumulating generated biogas inside a gas accumulation plate; extruding biogas slurry inside the fermentation chamber to flow to a feeding hole, a discharge hole, a turbulent flow area and a bacterium distribution drainage tube, thereby increasing the level of the biogas slurry inside the feeding hole, the discharge hole, the turbulent flow area and the bacterium distribution drainage tube continuously; when the level of the biogas slurry inside the discharge hole reaches a drainage tube of the discharge hole, enabling the biogas slurry to flow to a water pressure chamber in a one way through the drainage tube of the discharge hole; and when the level of the biogas slurry inside the water pressure chamber reaches a drainage tube at the discharge hole, enabling the biogas slurry inside the fermentation chamber to flow to the water pressure chamber in one way from the drainage tube at the feeding hole and the drainage tube at the discharge hole.

Owner:方华椿

Clog-free fermentation system for microbial organic waste decomposition and clean energy production

InactiveCN105925468AAvoid breakingAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsDecompositionAgricultural engineering

The invention discloses a clog-free fermentation system for microbial organic waste decomposition and clean energy production. The clog-free fermentation system comprises a fermentation tank body, a gas storage plate installed in the fermentation tank body, a water pressure chamber installed in the fermentation tank body and an orifice partition plate partitioning the fermentation tank body, wherein the fermentation tank body is of a circular-ring-shaped structure, the top of a bacterium distributing pipeline is connected with the water pressure chamber, the bottom of the bacterium distributing pipeline is connected with the bacterium distributing pipeline, and the bacterium distributing pipeline is arranged in the route direction of a fermentation chamber and is provided with a plurality of bacterium distributing holes penetrating in the vertical direction. A feeding port water drainage pipe is provided with a one-way valve for controlling one-way inflow of biogas slurry in a feeding port towards the water pressure chamber, a discharging port water drainage pipe is provided with a one-way valve for controlling one-way inflow of biogas slurry in a discharging port towards the water pressure chamber, a bacterium distributing device is provided with a one-way valve for controlling one-way inflow of biogas slurry in the water pressure chamber towards the fermentation chamber, and a bacterium distributing water drainage pipe in the vertical direction is connected to the bottom of the water pressure chamber.

Owner:方华椿

Panlong-type fermentation system for preparing new energy resource by using organic wastes of lives

InactiveCN105950450AAvoid breakingAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsNew energyAgricultural engineering

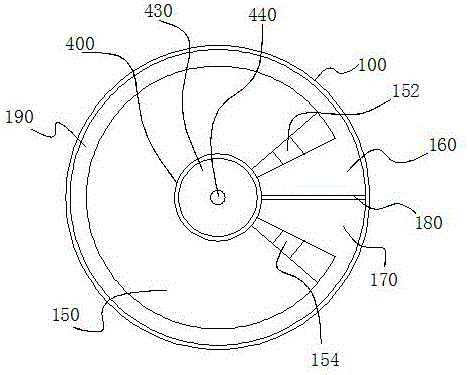

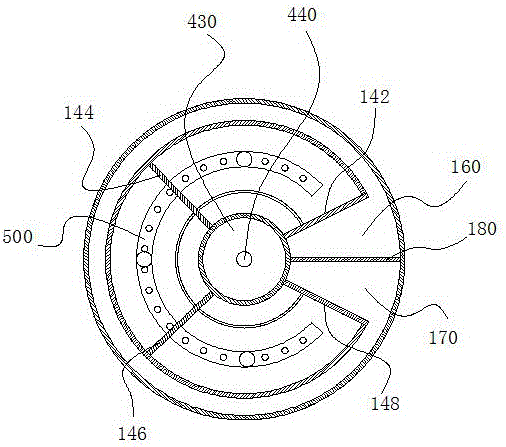

The invention discloses a panlong-type fermentation system for preparing a new energy resource by using organic wastes of lives. The fermentation system comprises a fermentation tank body, gas storage plates, hydraulic rooms and a feed gate partition board, wherein the gas storage plates are mounted in the fermentation tank body, the hydraulic rooms are mounted in the fermentation tank body, and the fermentation tank body is partitioned by the feed gate partition board; the fermentation tank body is of a circular-ring-shaped structure, the top of a strain distribution drain pipe is connected with the hydraulic rooms, the bottom of the strain distribution drain pipe is connected with a strain distribution pipeline, the strain distribution pipeline is arranged along the path direction of a fermentation chamber, and a plurality of strain distribution holes which are penetrative in the vertical direction are formed in the strain distribution pipeline.

Owner:方华椿

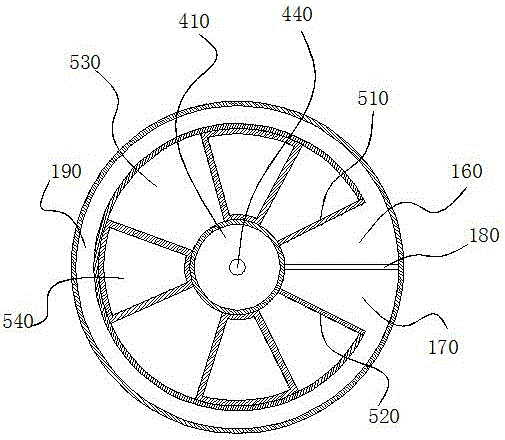

Plant straw anaerobic fermentation treating system capable of achieving pneumatic distribution

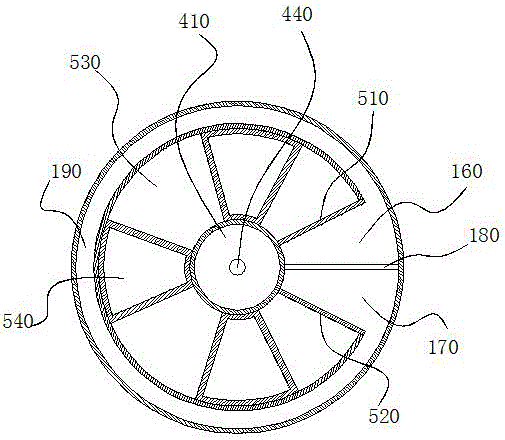

InactiveCN105907612AIncrease the maximum capacityEnhance biogas slurry self-convectionBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasAgricultural engineering

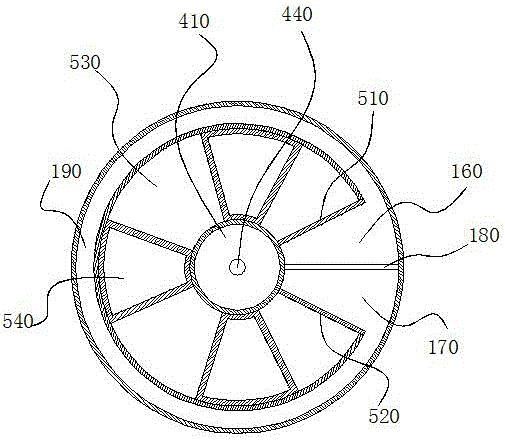

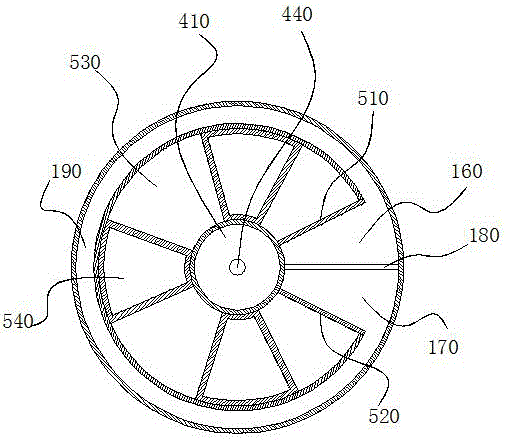

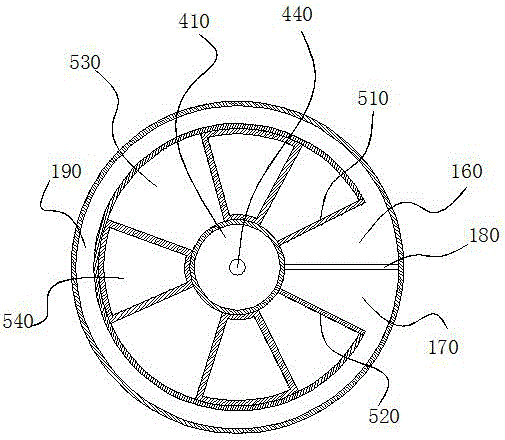

The invention discloses a plant straw anaerobic fermentation treating system capable of achieving pneumatic distribution. The system comprises a fermentation tank body, a gas storage plate installed in the fermentation tank body, a hydraulic pressure room installed in the fermentation tank body, a material opening separation plate for separating the fermentation tank body and an auxiliary gas storage device connected with the gas storage plate. The fermentation tank body is of an annular structure. The hydraulic pressure room is further connected with a turbulence bacteria distribution device which is composed of a plurality of middle drainage pipes arranged on the hydraulic pressure room. The middle drainage pipes are located between a feed inlet end drainage pipe and a discharge outlet end drainage pipe. The middle drainage pipes are distributed in the direction of the fermentation path. The feed inlet end drainage pipe is provided with a one-way valve enabling biogas slurry in the hydraulic pressure room to flow into a feed inlet in one way, and the discharge outlet end drainage pipe is provided with a one-way valve enabling biogas slurry in a discharge outlet to flow into the hydraulic pressure room in one way. The middle drainage pipe is provided with a one-way valve enabling biogas slurry in the hydraulic pressure room to flow into a fermentation cavity in one way.

Owner:李俊

Straw fermentation treatment system for promoting turbulent flow stirring bacterium distribution

InactiveCN105907614AAvoid breakingIncrease the maximum capacityBioreactor/fermenter combinationsBiological substance pretreatmentsSlurryFermentation

The invention discloses a straw fermentation treatment system for promoting turbulent flow stirring bacterium distribution. The system comprises a fermentation tank, a gas storage plate installed in the fermentation tank, a water pressure chamber installed in the fermentation tank, a material opening partition plate for partitioning the fermentation tank, and an auxiliary gas storage device connected with the gas storage plate. The fermentation tank is of an annular structure. The water pressure chamber is connected with turbulent bacterium distribution devices which are middle drainage pipes arranged on the water pressure chamber. The middle drainage pipes are located between feed port end drainage pipes and discharge port end drainage pipes. The middle drainage pipes are distributed along a fermentation path. One-way valves for controlling biogas slurry in the water pressure chamber to flow into a feed port in one way are arranged on the feed port end drainage pipes. One-way valves for controlling the biogas slurry in a discharge port to flow into the water pressure chamber are arranged on the discharge port end drainage pipes. One-way valves for controlling the biogas slurry in a fermentation chamber to flow into the water pressure chamber in one way are arranged on the middle drainage pipes.

Owner:李俊

System for preparing new energy sources by industrial or life organic waste

InactiveCN105950449AAvoid breakingAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsWater dischargeNew energy

The invention discloses a system for preparing new energy sources by industrial or life organic waste. The system comprises a fermentation tank body, a gas storage plate, a water pressure chamber and a material opening separation plate, wherein the gas storage plate is arranged in the fermentation tank body; the water pressure chamber is arranged in the fermentation tank body; the material opening separation plate separates the fermentation tank body; the water pressure chamber is provided with a material feeding opening water discharge pipe extending into a feeding opening; the water pressure chamber is provided with a discharging opening water discharge pipe extending to a discharging opening; the material opening separation plate is detachably connected with the fermentation tank body; a one-way valve for biogas slurry in the discharging opening to flow into the water pressure chamber in one way is arranged on the discharging opening water discharge pipe; a one-way valve for controlling the biogas slurry in the water pressure chamber to flow into the feeding opening is arranged on the feeding opening water discharge pipe.

Owner:方华椿

Method for producing clean energy through turbulence stirring type anaerobic fermentation system

InactiveCN105886373AAvoid breakingAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsSlurryClean energy

The invention discloses a method for producing clean energy through a turbulence stirring type anaerobic fermentation system. Fermentation raw materials ferment in a fermentation chamber and produce biogas, the produced biogas is accumulated in a biogas storage plate, the biogas pressure in the biogas storage plate gradually increases and extrudes biogas slurry in the fermentation chamber to flow to a feed port, a discharge port and a turbulence section, the liquid level of the biogas slurry in the feed port, the discharge port and the turbulence section constantly rises, and biogas slurry in the fermentation chamber is made to flow into a water pressure chamber in one direction through bacterial distribution holes; when a biogas guiding pipe is used for guiding the biogas in the biogas storage plate out, the biogas pressure in the biogas storage plate descends, the biogas slurry stored in the water pressure chamber flows back and flows into the feed port in one direction through a water drainage pipe of the feed port, and the biogas slurry rich in bacteria is brought into the feed port.

Owner:李俊

Method for producing new energy by means of pneumatic turbulent flow strain distribution type anaerobic fermentation treatment system

InactiveCN105969643AEvenly distributedAchieve multiple fermentationsBioreactor/fermenter combinationsBiological substance pretreatmentsNew energyDecomposition

The invention discloses a method for producing new energy by means of a pneumatic turbulent flow strain distribution type anaerobic fermentation treatment system. A material port separation plate is taken out, and a stirring rod is pulled to conduct stirring in the annular direction from a feed inlet to a discharge outlet, so that uniform distribution of fermentation materials is promoted and the biogas residues near the discharge outlet are brought to a position near the feed inlet; a large number of strains exist in the biogas residues, the biogas residues are broken during stirring, and then uniform distribution of the strains in the fermentation system is effectively promoted; the biogas residues flow back to a fermentation chamber to be fermented again, repeated fermentation of fermentation materials is realized, sufficient decomposition is promoted, and the utilization rate of energy is increased.

Owner:李俊

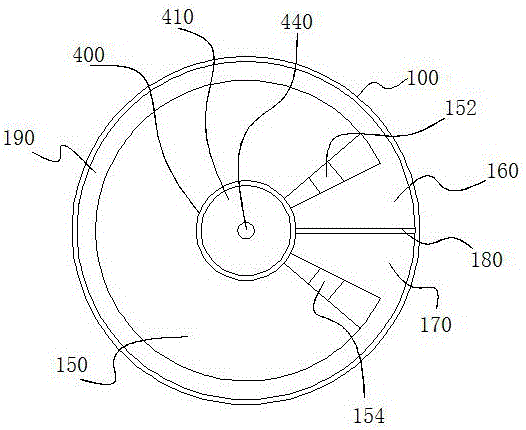

Method for generating new energy through straw anaerobic treatment system achieving partition convective stirring

InactiveCN105907794AIncrease the maximum capacityEnhance biogas slurry self-convectionBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasAnaerobic treatment

The invention discloses a method for generating new energy through a straw anaerobic treatment system achieving partition convective stirring. Sub-fermentation regions and auxiliary fermentation regions are arranged in a gas storage plate, the auxiliary fermentation regions are arranged below an auxiliary gas storage plate, independent fermentation regions are formed between feed / discharge port gas baffles and the walls of the adjacent auxiliary fermentation regions or between the walls of the adjacent auxiliary fermentation regions, and fermentation raw materials and strains are not uniformly distributed, so that the pressure of biogas in the auxiliary fermentation regions is not consistent with the pressure of biogas in the adjacent sub-fermentation regions, and the biogas slurry is promoted to be subjected to convection between the auxiliary fermentation regions and the sub-fermentation regions; when the biogas slurry in a fermentation cavity is lower than the bottom of an inner vertical plate of the auxiliary gas storage plate, the storage amount of the biogas in the auxiliary gas storage plate is maximum, and the biogas continuing to be collected in the auxiliary gas storage plate overflows from the bottom of the inner vertical plate.

Owner:李俊

Straw fermentation treating method for promoting bacteria distribution through multi-zone convective stirring

InactiveCN105886375AAvoid breakingAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsSlurryAtmospheric pressure

The invention discloses a straw fermentation treating method for promoting bacteria distribution through multi-zone convective stirring. When a fermentation raw material enters a fermentation cavity for fermentation to produce marsh gas, the gas pressure of marsh gas in a gas storage plate is increased, and biogas slurry in a fermentation cavity is squeezed to flow to a feed inlet, a discharge outlet and a turbulent interval. A one-way valve for controlling biogas slurry in a hydraulic pressure room to flow into the feed inlet in one way is arranged on a feed inlet drainage pipe, a one-way valve for controlling biogas slurry in a discharge outlet to flow into the hydraulic pressure room in one way is arranged on a discharge outlet drainage pipe, and the position, provided with bacteria distribution holes, of the hydraulic pressure room is higher than the joint of the discharge outlet drainage pipe and the hydraulic pressure room.

Owner:李俊

Method for preparing clean energy by decomposing organic refuse with microbes and performing fermentation

InactiveCN105886336AAvoid breakingAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsLitterSlurry

The invention discloses a method for preparing a clean energy by decomposing organic refuse with microbes and performing fermentation. The method comprises the following steps: feed process: after a feed port separation board separates the feed port from the discharge port, the fermentation raw material is poured into the feed port, a stirring rod is pulled to stir from the feed port to the discharge port in a burbling zone, thereby promoting the fermentation raw material to penetrate into the fermentation system and also promoting the uniform distribution of the fermentation raw material; and fermentation process: the fermentation raw material is fermented in a fermentation chamber to generate biogas, the generated biogas is accumulated in a gas storage plate, the biogas in the gas storage plate extrudes the biogas slurry in the fermentation chamber to flow to the feed port, discharge port, burbling zone and bacterium distribution drainage pipe as the gas pressure gradually increases, and the liquid level of the biogas slurry in the feed port, discharge port, burbling zone and bacterium distribution drainage pipe also continuously increases, so that the biogas slurry in the discharge port is discharged into a one-way water-pressure chamber through a discharge port drainage pipe.

Owner:方华椿

Method for decomposing organic matter garbage and preparing clean energy through self-living type anaerobic fermentation system

InactiveCN105886549AAvoid breakingAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsSlurryEngineering

The invention discloses a method for decomposing organic matter garbage and preparing clean energy through a self-living type anaerobic fermentation system. Along with continuous rise of the liquid level of biogas slurry in a feed port, a discharge port and a turbulent flow interval, the biogass slurry in a fermentation chamber flows into a water pressure chamber in one way through bacterium distribution holes firstly, and when the liquid level of the biogas slurry in the water pressure chamber rises to the position of a discharge port drainage pipe, the biogas slurry in the discharge port flows into the water pressure chamber in one way through the discharge port drainage pipe; when biogas in a gas storage plate is guided out through a gas guide pipe, the pressure of the biogas in the gas storage plate is reduced, the biogas slurry accumulated in the water pressure chamber flows back and flows into the feed port in one way through a feed port drainage pipe, the volume of the biogas reduced in the gas storage plate is supplemented, one-time biogas slurry self-circulation convection is completed accordingly, and in the biogas slurry convection process, uniform distribution of strains is promoted, and the fermentation efficiency of the system is improved.

Owner:李俊

Anaerobic fermentation processing and clean energy obtaining method for kitchen organic waste

InactiveCN105969649AAvoid breakingAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsSlurryMethane gas

The invention discloses an anaerobic fermentation processing and clean energy obtaining method for kitchen organic waste. Due to the fact that distribution of fermentation raw materials, strains and other factors are not uniform, methane gas pressure in a gas storage plate is not consistent with methane gas pressure in an auxiliary gas storage plate; when the methane gas pressure in the auxiliary gas storage plate is larger than the methane gas pressure in the gas storage plate, part of biogas slurry accumulated in the auxiliary gas storage plate is squeezed into an inner hydraulic pressure cylinder, the liquid level in the inner hydraulic pressure cylinder is raised, and the other part of the biogas slurry is squeezed into a fermentation cavity in the bottom of the gas storage plate; when the liquid level of the biogas slurry in the auxiliary gas storage plate is lower than the plane of the bottom of an inner vertical plate, the biogas storage quantity in the auxiliary gas storage plate reaches the maximum degree, biogas continuously collected in the auxiliary gas storage plate overflows through the bottom of the inner vertical plate and flows into the gas storage plate, and when the liquid level of the biogas slurry in the fermentation cavity reaches the horizontal plane of the bottom of a gas barrier plate at a material in-out opening, the biogas storage quantity of the system reaches the maximum degree, in other words, the biogas storage quantity is the sum of the biogas quantity accumulated in the gas storage plate and the biogas quantity accumulated in the auxiliary gas storage plate.

Owner:李俊

Method for preparing new energy resources by organic waste through self-convection stirring type fermentation system

InactiveCN105886334AAvoid breakingAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsNew energySlurry

The invention discloses a method for preparing new energy resources by organic waste through a self-convection stirring type fermentation system. The method comprises the following steps: a charging process: pouring fermentation raw materials into a charging hole, pulling a stirring rod to stir in a direction from the charging hole to a discharging hole within a turbulent-flow region, prompting the fermentation raw materials to go deep into a fermentation system, thereby promoting uniform distribution of fermentation raw materials; and a fermenting process: gathering biogas in a gas storage plate and extruding biogas slurry in a fermentation chamber to flow into the charging hole, the discharging hole, the turbulent-flow region and a bacterium arranging and drainage tube when the fermentation raw materials are fermented in the fermentation chamber to generate biogas, and enabling the biogas slurry in the discharging hole to flow into a water pressure room through a discharging hole draining tube in a one-way manner along with the continuous rise of the biogas slurry in the charging hole, the discharging hole, the turbulent-flow region and the bacterium arranging and drainage tube.

Owner:方华椿

Method for preparing renewable energy by using plant straws as raw material

InactiveCN105969648AAvoid breakingAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringSlurry

This invention discloses a method for preparing renewable energy by using plant straws as a raw material. When the raw materials fermented in a fermentation chamber produces biogas, the biogas accumulates in a gas storage plate and an auxiliary gas storage plate, and biogas slurry in the fermentation chamber is extruded to flow towards a feeding / discharging port. When the biogas slurry level reaches to a water draining pipe of the feeding port and a water draining pipe of the discharging port, the biogas slurry containing strains in the discharging port flows into the water pressure chamber in a one-way mode due to the fact that a one-way valve for making the biogas slurry in a water pressure chamber flow towards the feeding port is arranged on the water draining pipe of the feeding port and a one-way valve for making the biogas slurry in the discharging port flow towards the water pressure chamber in a one-way mode is arranged on the water draining pipe of the discharging port.

Owner:李俊

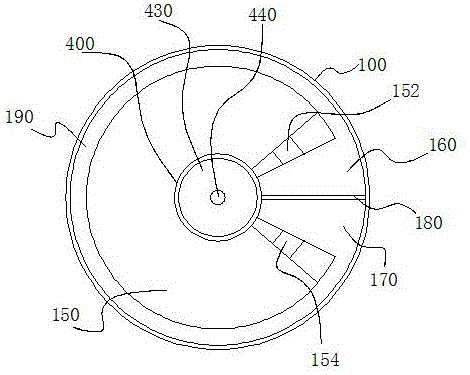

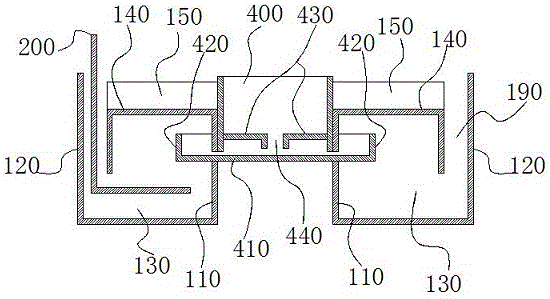

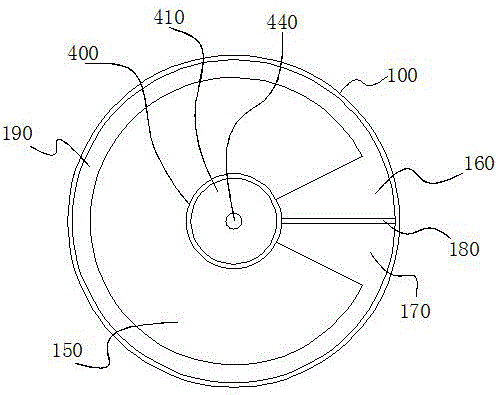

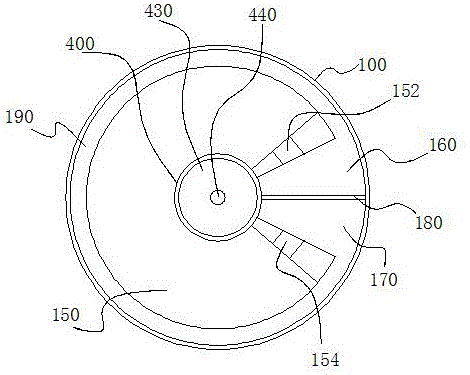

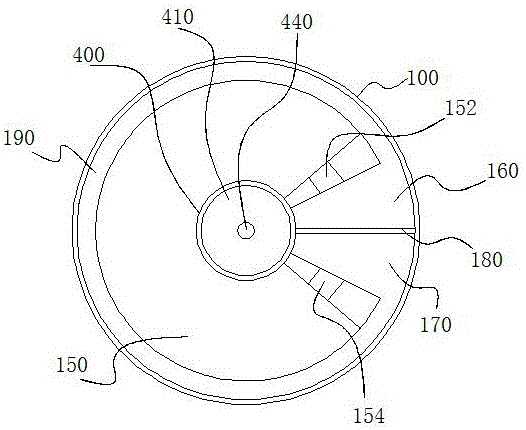

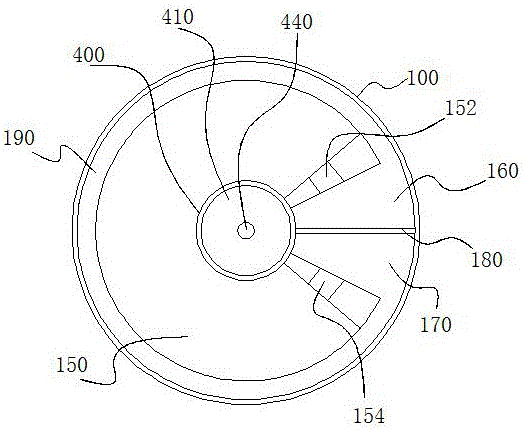

Turbulence stirring type anaerobic fermentation system for preparing clean energy

InactiveCN105886374AAvoid breakingAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsClean energyMechanical engineering

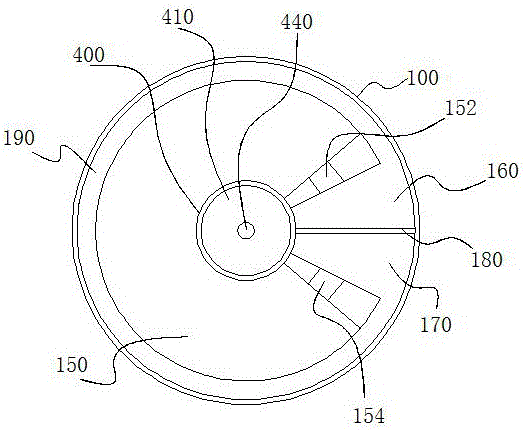

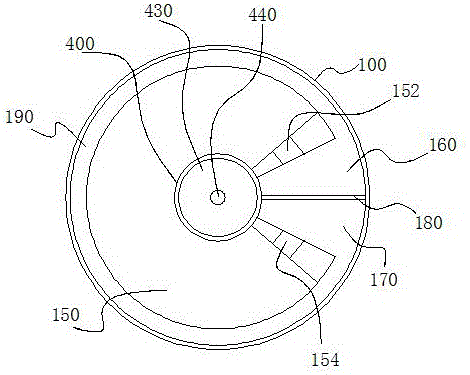

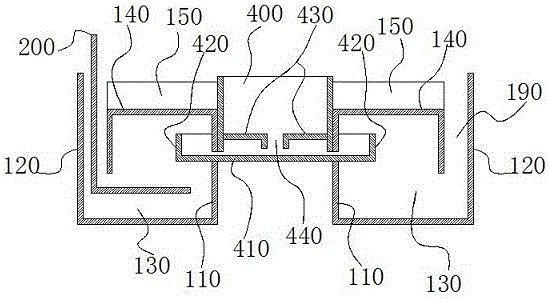

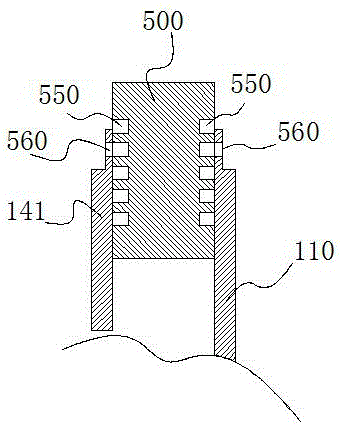

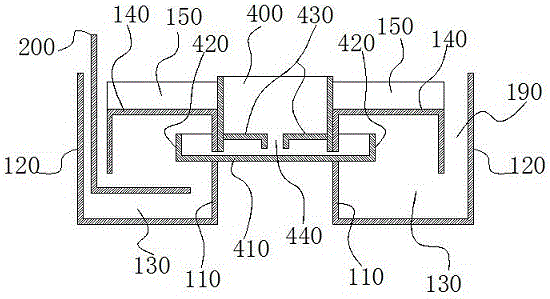

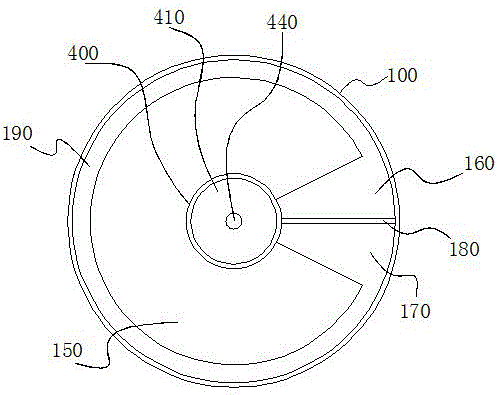

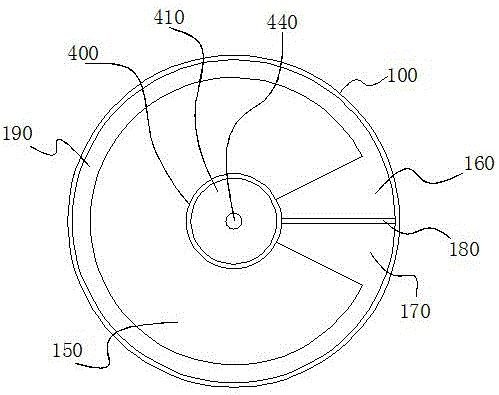

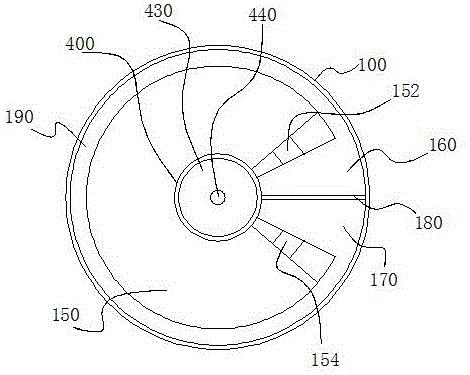

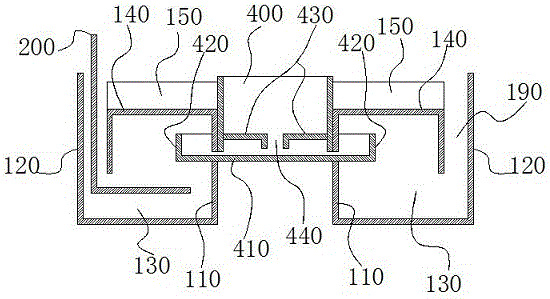

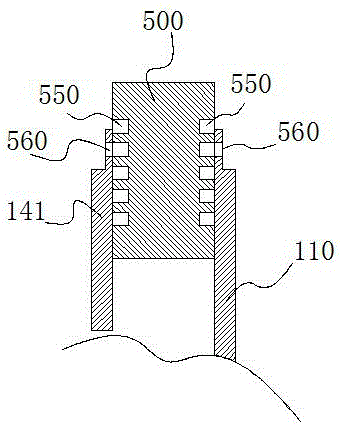

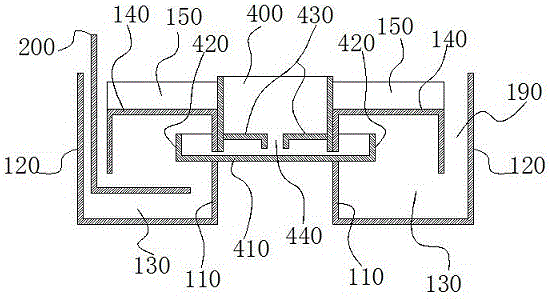

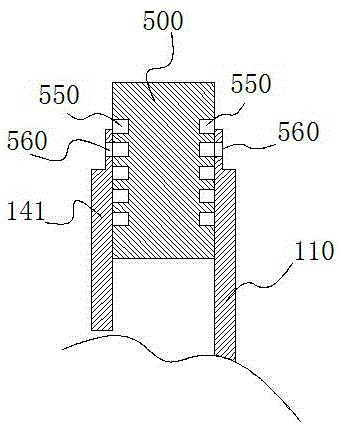

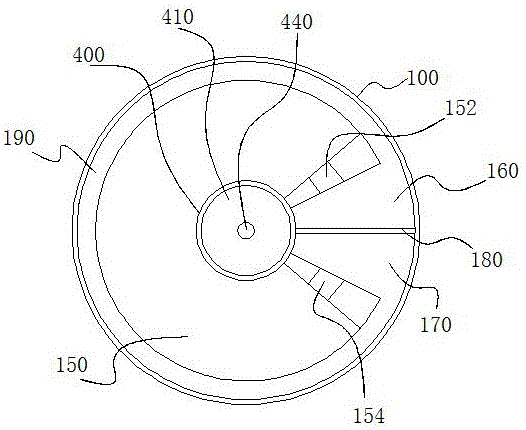

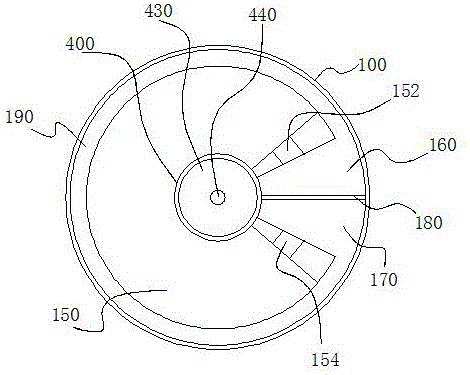

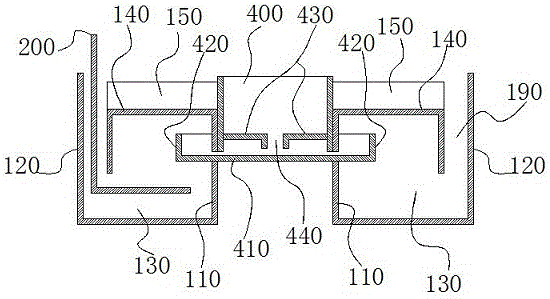

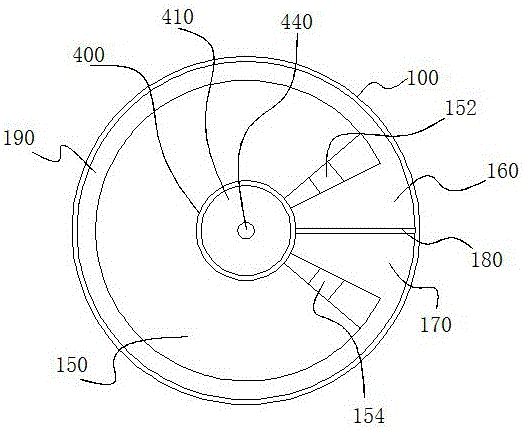

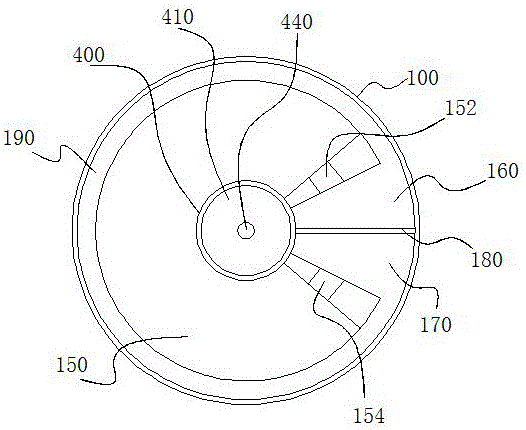

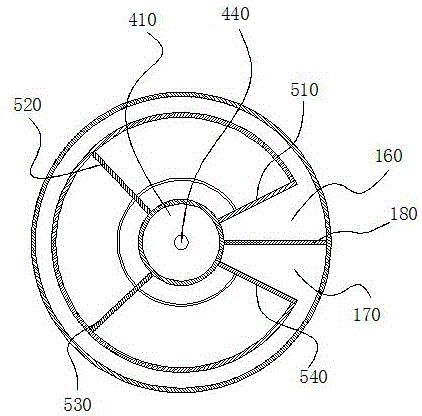

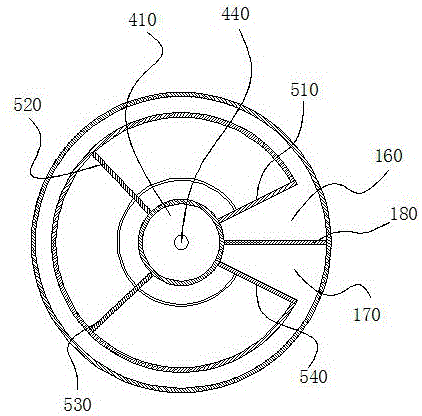

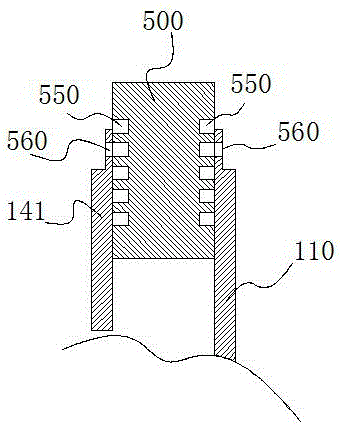

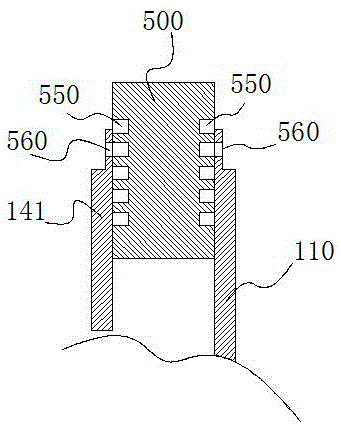

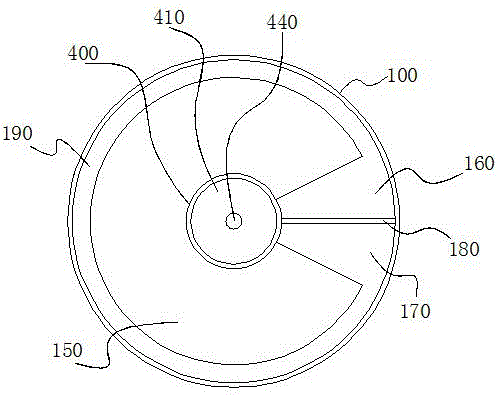

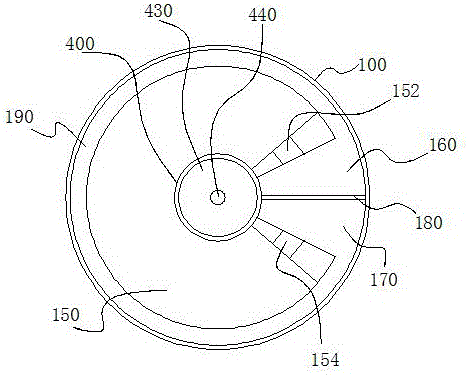

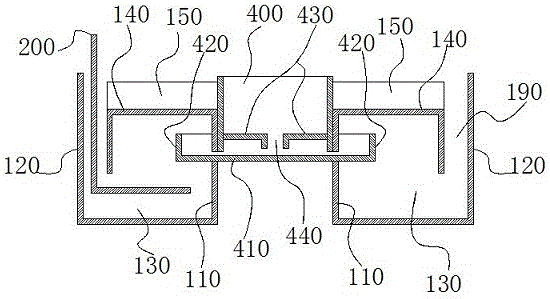

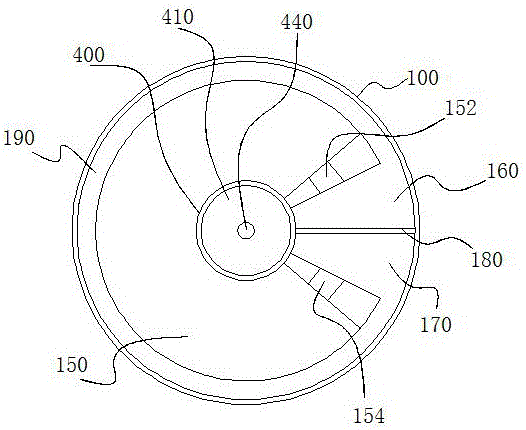

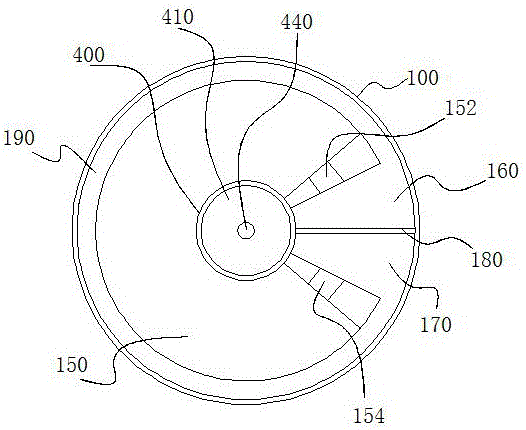

The invention discloses a turbulence stirring type anaerobic fermentation system for preparing clean energy. The system comprises a material opening partition plate for partitioning a fermentation tank. The material opening partition plate comprises a material opening main plate and a flow baffle movably connected with the material opening main plate. The inner wall and the outer wall of the tank are each provided with a guide groove matched with the material opening main plate. The material opening main plate is inserted into the guide grooves to be located. A circular flow opening is formed in the upper portion of the material opening main plate. A guide groove located in the vertical direction and matched with the flow baffle is formed in the material opening main plate. When the flow baffle moves downwards, the circular flow opening can be covered with the flow baffle.

Owner:李俊

Harmless organic matter treatment method based on anaerobic fermentation technique

InactiveCN105969646AEvenly distributedImprove filtration efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsEnvironmental engineeringSlurry

The invention discloses a harmless organic matter treatment method based on the anaerobic fermentation technique. Non-uniform distribution of fermentation materials and strains causes inconsistency of pressure of biogas in a gas storage plate and pressure of biogas in an auxiliary gas storage plate. When the pressure of biogas in the auxiliary gas storage plate is larger than that in the gas storage plate, part of biogas slurry accumulated in the auxiliary gas storage plate is squeezed into an inner water pressure cylinder to enable the liquid level in the inner water pressure cylinder to increase, and the other part of biogas slurry is squeezed into a fermentation chamber on the bottom of the gas storage plate; when the liquid level of biogas slurry in the auxiliary gas storage plate is lower than the bottom plane of an inner vertical plate, the storage amount of biogas in the auxiliary gas storage plate is the largest, biogas collected by the auxiliary gas storage plate continuously will overflow through the bottom of the inner vertical plate and flow into the gas storage plate, and when the liquid level of biogas slurry in the fermentation chamber reaches the horizontal plane of the bottom of a feed inlet / outlet gas baffle, the storage amount of biogas in the system is the largest and is the sum of the amount of biogas accumulated in the gas storage plate and the amount of biogas in the auxiliary gas storage plate.

Owner:李俊

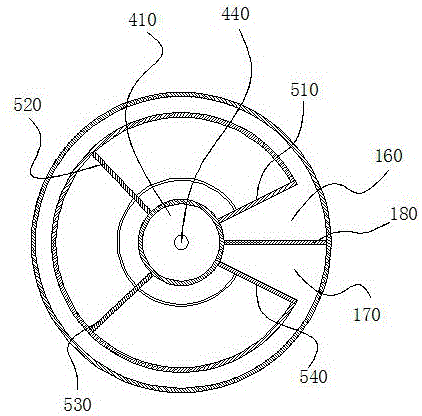

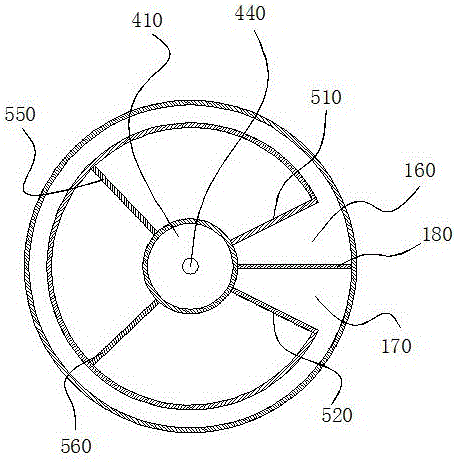

Organic matter anaerobic fermentation processing system based on circulation stirring

InactiveCN105907624AAvoid breakingAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringOrganic matter

The invention discloses an organic matter anaerobic fermentation processing system based on circulation stirring. The system comprises material opening partition plate used for separating a fermentation tank body. The material opening partition plate comprises a material opening main plate, and a flow blocking plate movably connected with the material opening main plate. The inner wall of the tank body and the outer wall of the tank body are each provided with a guide groove matched with the material opening main plate. The material opening main plate is inserted into the guide grooves to achieve positioning of the material opening main plate. The upper portion of the material opening main plate is provided with a circulation flow opening. The material opening main plate is provided with a guide groove matched with the flow blocking plate in the vertical direction. When moving downwards, the flow blocking plate can cover a circulation flowing opening.

Owner:李俊

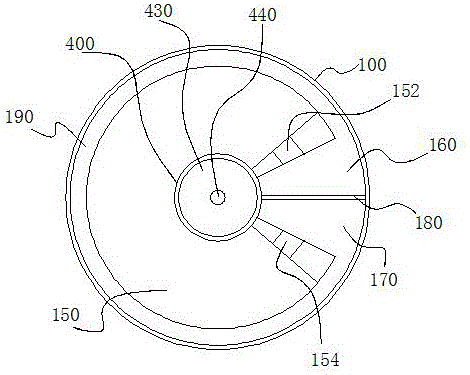

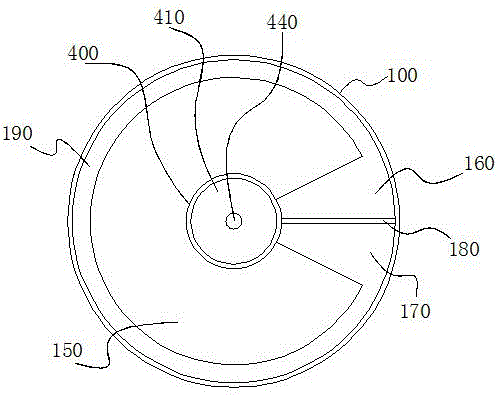

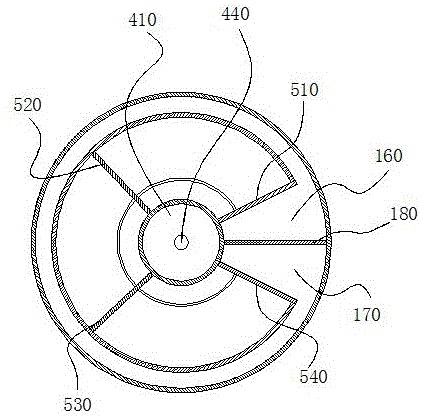

System for preparing renewable energy by taking plant straw as raw material

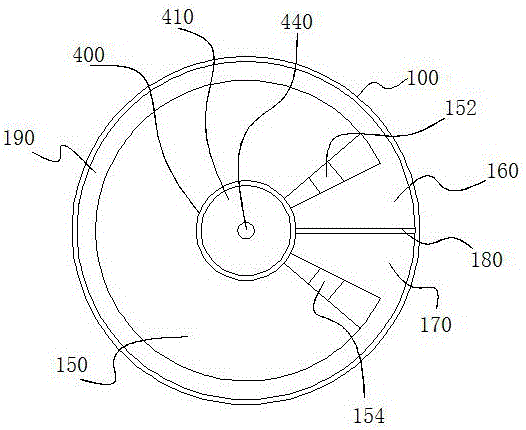

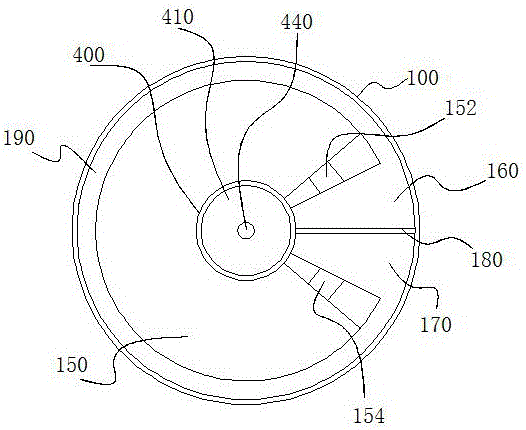

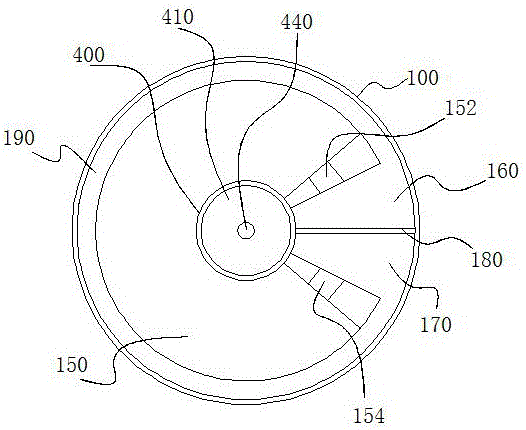

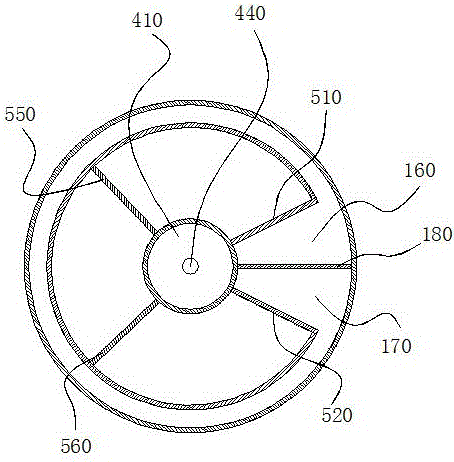

InactiveCN105907621AIncrease the maximum capacityAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsRenewable energyEngineering

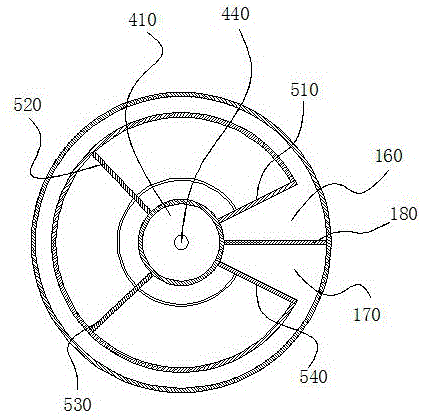

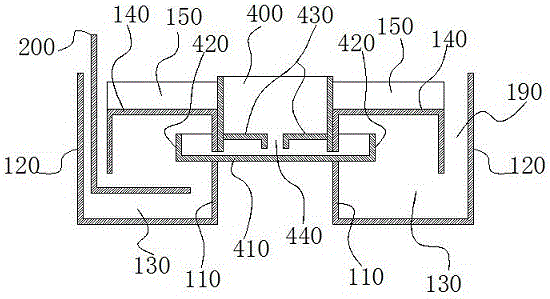

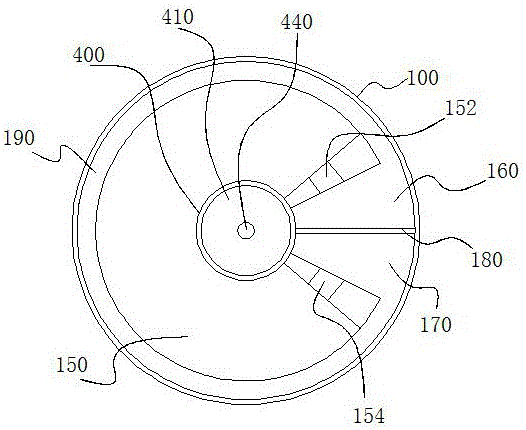

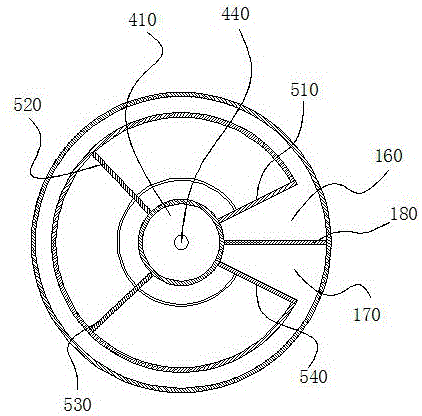

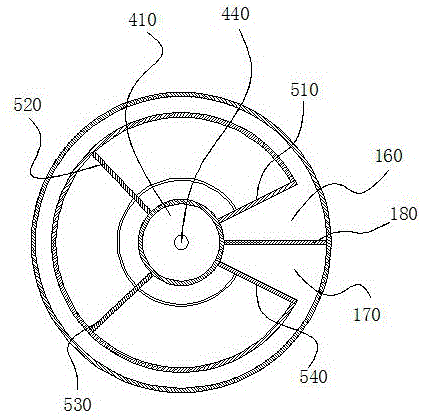

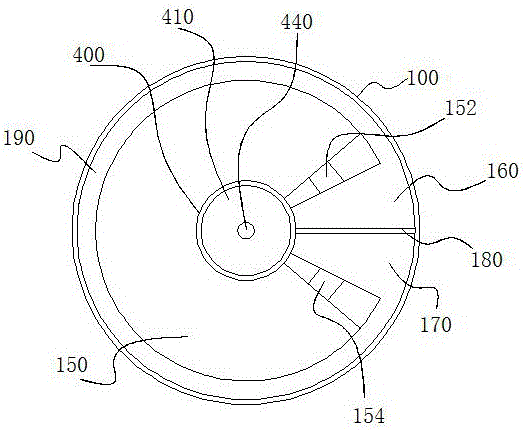

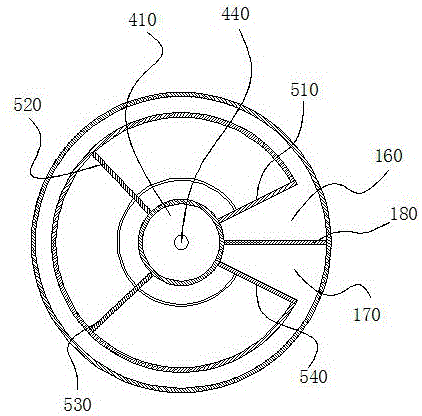

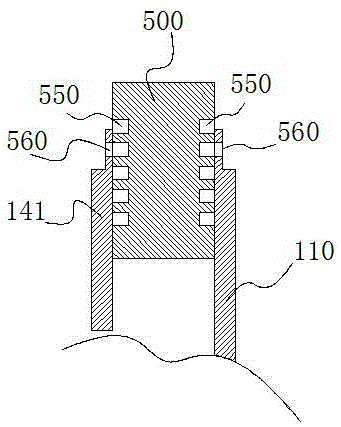

The invention discloses a system for preparing renewable energy by taking plant straw as a raw material. The system comprises gas storage plates, a disturbed flow interval is formed between the gas storage plate wall of each gas storage plate and the outer wall of a tank body in a spaced mode, the disturbed flow intervals extend in the outer wall direction of the tank body, and a stirring rod is movably arranged in each disturbed flow interval; a water pressure chamber is installed on each gas storage plate, and each water pressure chamber is provided with a feed opening drainage pipe extending to a feed opening and a discharge opening drainage pipe extending to a discharge opening; the bottom of a feed opening gas baffle plate and the bottom of a discharge opening gas baffle plate are located on a same horizontal plane, the horizontal plane where the bottoms of the gas storage plate walls of the gas storage plates are located is not higher than the horizontal plane where the bottom of the feed opening or discharge opening gas baffle plate is located, gaps are formed between the gas storage plate walls and the bottom of the fermenting tank body, the horizontal plane where the top of the inner wall of the tank body is located is lower than the horizontal plane where the top of the outer wall of the tank body is located, and the horizontal plane where the top of the outer wall of the tank body is located is higher than the horizontal plane where the tops of the water pressure chambers are located.

Owner:李俊

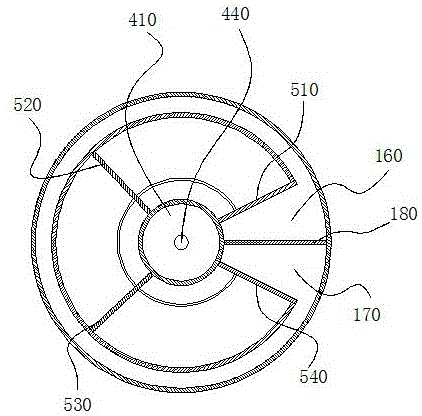

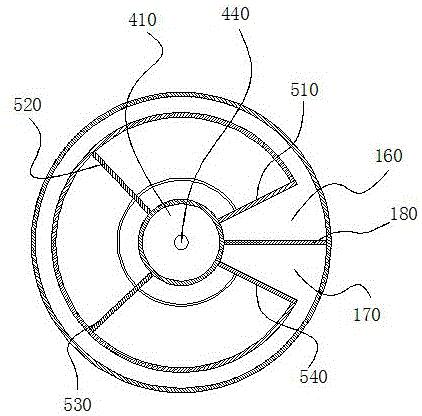

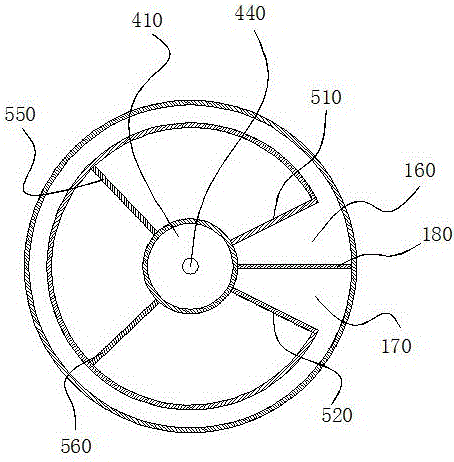

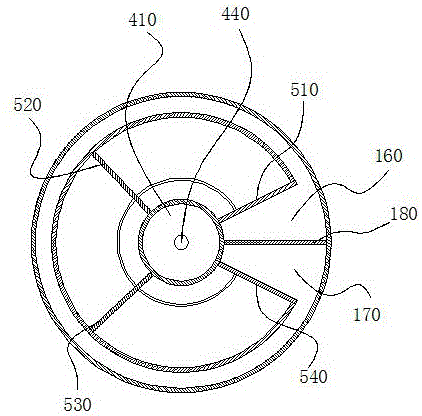

System for carrying out anaerobic fermentation treatment on kitchen organic refuse and acquiring clean energy

InactiveCN105907625AAvoid breakingAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsWater flowEngineering

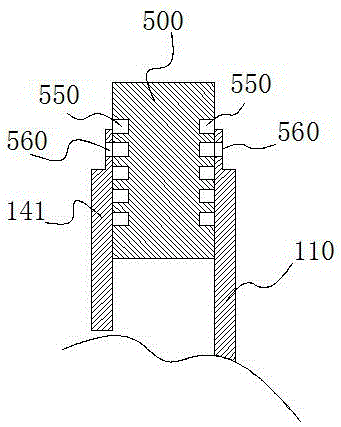

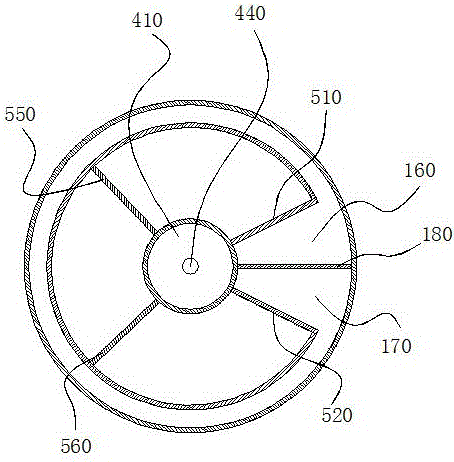

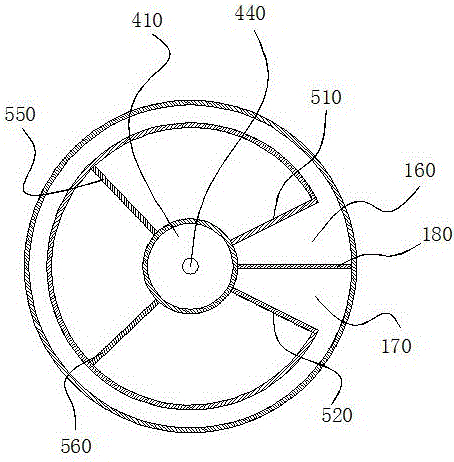

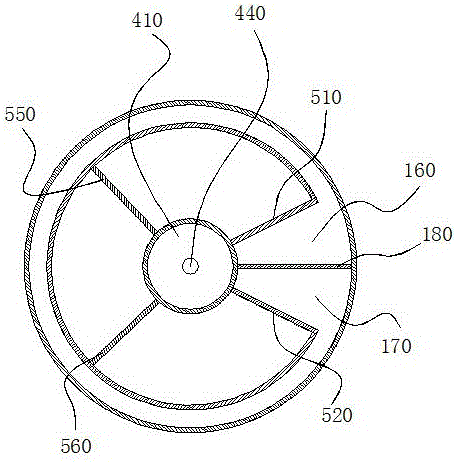

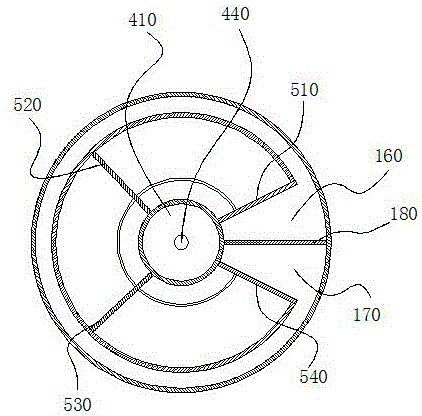

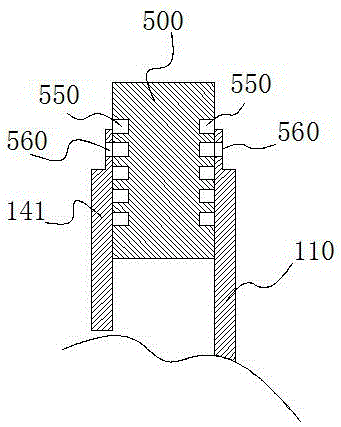

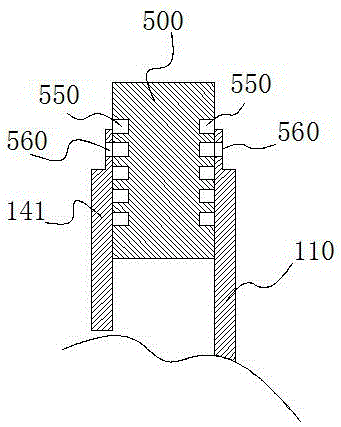

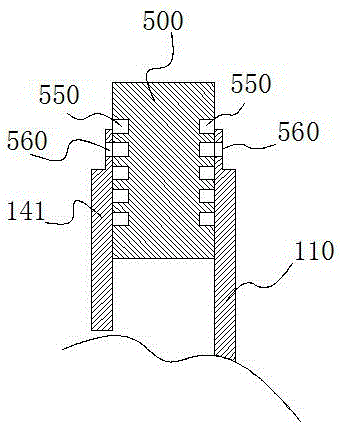

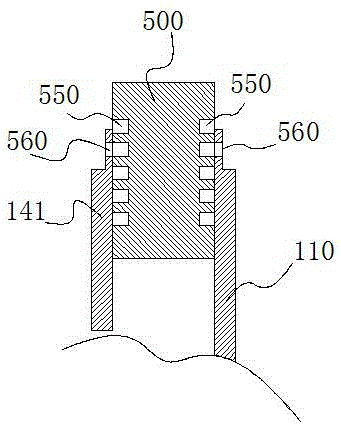

The invention discloses a system for carrying out anaerobic fermentation treatment on kitchen organic refuse and acquiring clean energy. The system comprises an auxiliary gas storage device connected with a gas storage plate. The auxiliary gas storage device comprises an inner water pressure column installed in the center of a fermentation tank, and an auxiliary gas storage plate which is installed in the inner water pressure column and stretches into a fermentation chamber. A first water flow hole is formed in the inner wall of the tank, and a second water flow hole corresponding to the first water flow hole is formed in the inner water pressure column. The auxiliary gas storage plate comprises an upper auxiliary plate, an inner vertical plate and an outer vertical plate. The horizontal plane where the bottom of the inner vertical plate is located is higher than the horizontal plane where the bottom of a feed / discharge port gas baffle is located. The horizontal plane where the bottom of the outer vertical plate is located is lower than the horizontal plane where the bottom of the feed / discharge port gas baffle is located.

Owner:李俊

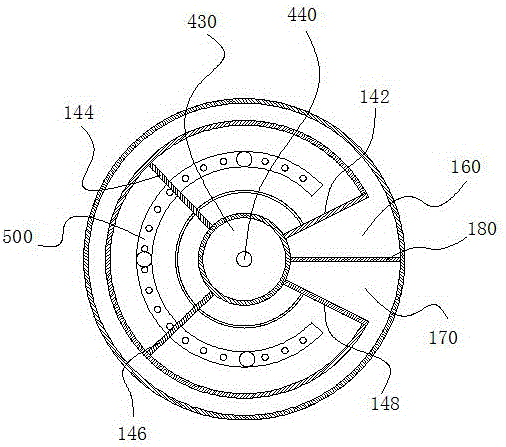

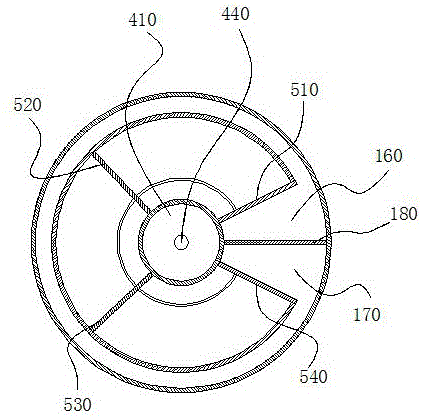

Anaerobic fermentation system for water pressure disturbed flow strain distribution

InactiveCN105886365AIncrease the maximum capacityEnhance biogas slurry self-convectionBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasPore water pressure

The invention discloses an anaerobic fermentation system for water pressure disturbed flow strain distribution. The system comprises a fermentation tank, a gas storage plate installed in the fermentation tank, a water pressure chamber installed in the fermentation tank, a feed inlet separation plate dividing the fermentation tank, and an auxiliary gas storage device connected with the gas storage plate. The fermentation tank is of a circular structure and comprises a tank inner wall and a tank outer wall, the area between the tank inner wall and the tank outer wall serves as a fermentation chamber, the fermentation chamber is circular, and a gas guide device is installed at the end, located in an inner water pressure column, of an auxiliary upper plate. A feed inlet end drainage pipe is provided with a one-way valve controlling biogas liquid in the water pressure chamber to flow in a feed inlet in one direction, and a discharge opening end drainage pipe is provided with a one-way valve controlling biogas liquid in a discharge opening to flow in the water pressure chamber.

Owner:李俊

Kitchen waste fermentation treatment system

InactiveCN105886333AAvoid breakingAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringFermentation

The invention discloses a kitchen waste fermentation treatment system. The system comprises a fermentation tank body, a gas storage plate arranged in the fermentation tank body, a hydraulic pressure chamber arranged in the fermentation tank body and an opening partition plate for partitioning the fermentation tank body, wherein a charging opening drain pipe extending to a charging opening is arranged in the hydraulic pressure chamber, and a discharge opening drain pipe extending to a discharge opening is arranged in the hydraulic pressure chamber; burble sections are spaced between the wall part of the gas storage plate and the outer wall of the tank body, and extend along the direction of the outer wall of the tank body; the bottom of the gas baffle of the charging opening and the bottom of the gas baffle of the tank body are positioned on the same horizontal plane; the horizontal surface of the bottom of the wall part of the gas storage plate is not higher than that of the gas baffle of the charging / discharge opening; a gap is reserved between the wall of the gas storage plate and the bottom of the fermentation tank body; the horizontal surface of the top of the inner wall of the tank body is lower than that of the outer wall of the tank body; and the horizontal surface of the top of the outer wall of the tank body is higher than that of the hydraulic pressure chamber.

Owner:方华椿

Annular non-blocking plant straw fermentation processing system

InactiveCN105907617AIncrease the maximum capacityEnhance biogas slurry self-convectionBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasAgricultural engineering

The invention discloses an annular non-blocking plant straw fermentation processing system which comprises a fermentation tank body, a gas storage plate installed in the fermentation tank body, a hydraulic pressure room installed in the fermentation tank body, a material opening partition plate for separating the fermentation tank body, and an auxiliary gas storage device connected with the gas storage plate. The fermentation tank body is of an annular structure. The hydraulic pressure room is further connected with a turbulence bacteria distribution device which is composed of a plurality of middle drainage pipes arranged on the hydraulic pressure room. The middle drainage pipes are located between a feed inlet end drainage pipe and a discharge outlet end drainage pipe and distributed in the direction of a fermentation path. The feed inlet end drainage pipe is provided with a one-way valve for controlling biogas slurry in the hydraulic pressure room to flow into a feed inlet in one way, the discharge outlet end drainage pipe is provided with a one-way valve for controlling biogas slurry in a discharge outlet to flow into the hydraulic pressure room in one way, and the joint of a middle drainage pipe and the hydraulic pressure room is higher than the discharge outlet end drainage pipe.

Owner:李俊

Self active type anaerobic fermentation system for preparing clean energy from industrial organic waste

InactiveCN105969647AAvoid breakingAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsSlurryClean energy

The invention discloses a self active type anaerobic fermentation system for preparing clean energy from industrial organic waste. The system comprises a water pressure chamber arranged on the top of a gas storage plate and an auxiliary gas storage device connected with the gas storage plate, and the water pressure chamber is installed above the gas storage plate and provided with a feed inlet drain pipe extending into a feed inlet and a discharge hole drain pipe extending into a discharge hole; the water pressure chamber is further provided with a bacterium distributing device which is composed of multiple bacterium distributing holes formed in the side wall, close to a turbulent flow interval, of the water pressure chamber, and the bacterium distributing holes are evenly distributed in the wall part of the gas storage plate at intervals; the feed inlet drain pipe is provided with a one-way valve which controls biogas slurry in the water pressure chamber to flow into the feed inlet in a one-way mode, the discharge hole drain pipe is provided with a one-way valve which controls biogas slurry in the discharge hole to flow into the water pressure chamber in a one-way mode, and the bacterium distributing holes are provided with a one-way valve which controls biogas slurry in a fermentation chamber to flow into the water pressure chamber in a one-way mode.

Owner:李俊

Method for carrying out fermenting treatment on industrial or organic garbage based on automatic moving and flowing technology

InactiveCN105886369AAvoid breakingAvoid blockingBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringFermentation

The invention discloses a method for carrying out fermenting treatment on industrial or organic garbage based on the automatic moving and flowing technology. The relative positions of a feeding port gas blocking plate, a discharging port gas blocking plate and a gas storing plate are adjusted, the lengths of the parts, extending into the gas storing plate, of the feeding port gas blocking plate and the discharging port gas blocking plate are controlled, and the lower the planes of the bottoms of the feeding and discharging port gas blocking plates are, the larger the biogas storing space is. According to the feeding process, fermentation raw materials are poured into a feeding port, a stirring rod is pulled to carry out stirring in the direction from the feeding port to a discharging port in the turbulent flow interval, and uniform distribution of the fermentation raw materials in a fermenting chamber is promoted.

Owner:李俊

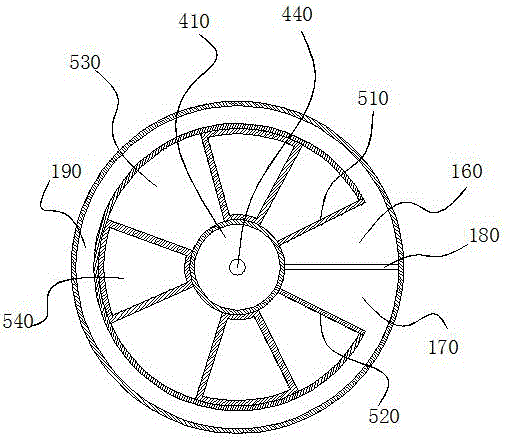

Spiral type anaerobic fermentation system for making clean energy from plant straw

InactiveCN105886378AEvenly distributedEnhanced convectionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringClean energy

The invention discloses a spiral type anaerobic fermentation system for making clean energy from plant straw. The system comprises a water pressure chamber on the top of a gas storage plate, and an auxiliary gas storage device connected with the gas storage plate. A bacteria distributing device is arranged on the water pressure chamber and comprises a plurality of bacteria distributing holes which are formed in the side wall, close to the flow disturbance area, of the water pressure chamber. The bacteria distributing holes are evenly distributed in the wall of the gas storage plate at intervals. The auxiliary gas storage device comprises an inner water pressure column body at the center of a fermentation tank body and an auxiliary gas storage plate installed in the inner water pressure column body and extending into a fermentation chamber. The auxiliary gas storage plate comprises an upper auxiliary plate, an inner vertical plate and an outer vertical plate. An opening of the auxiliary gas storage plate formed by the upper auxiliary plate, the inner vertical plate and the outer vertical plate faces downwards. The horizontal plane where the bottom of the inner vertical plate is located is higher than the horizontal plane where the bottom of a feed / discharge port gas baffle is located. The horizontal plane where the bottom of the outer vertical plate is located is lower than the horizontal plane where the bottom of the feed / discharge gas baffle is located.

Owner:李俊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com