Photochemical paper pulp bleaching method and device

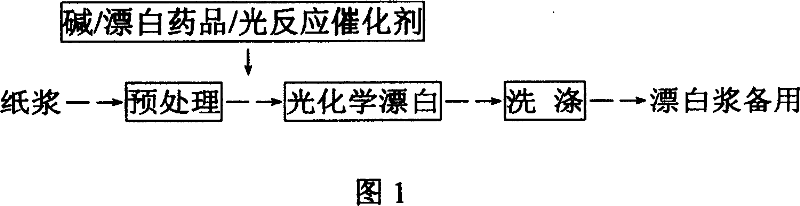

A photochemical and photochemical reaction technology, applied in the field of pulp and paper, can solve the problems of bleaching wastewater that cannot be closed and circulated, requires high corrosion resistance, and large pollution, and achieves low anti-corrosion performance requirements, high physical strength, and delignification high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

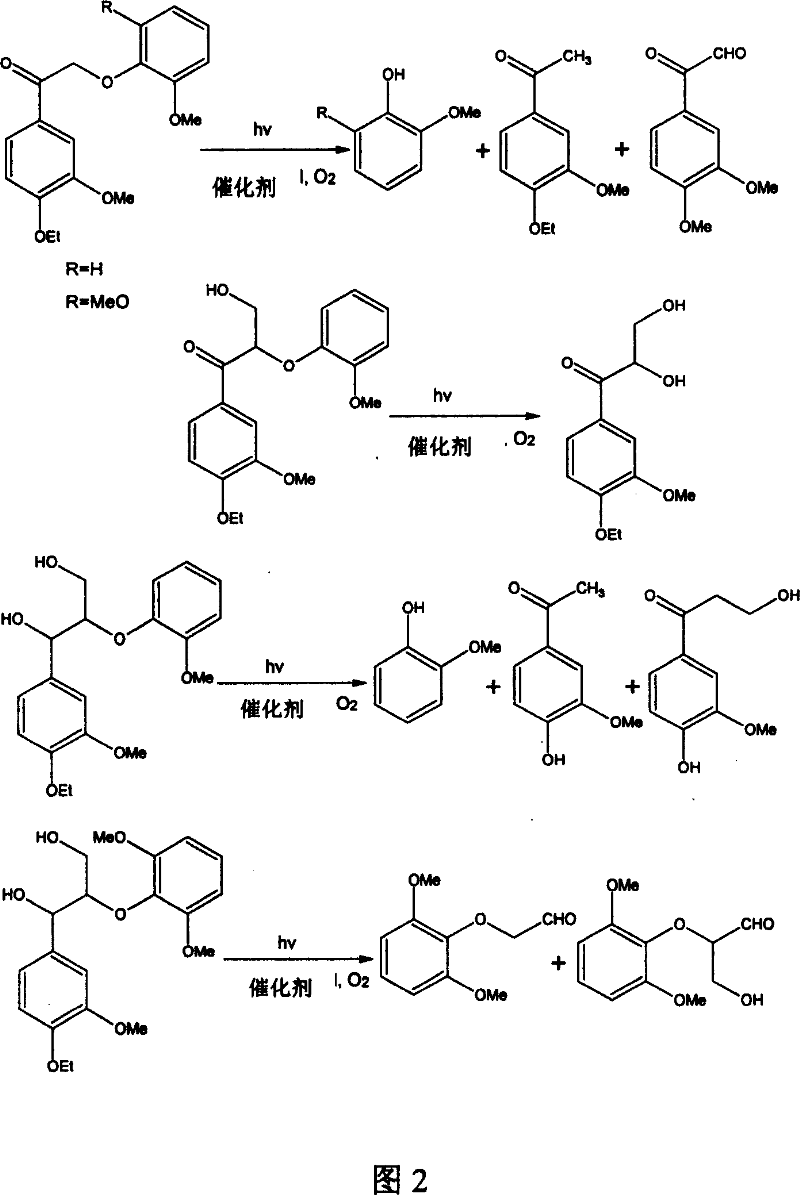

Method used

Image

Examples

Embodiment 1

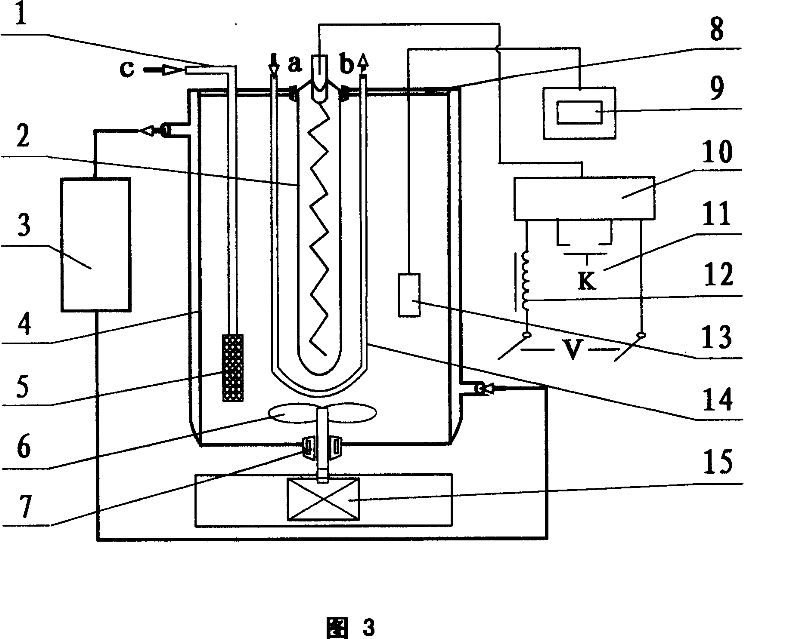

[0037] Embodiment 1, after paper pulp is dispersed, add water to make the suspension of 0.5-5% concentration, through the 0.05-1% EDTA solution pretreatment of 15-60 minute by absolute dry paper pulp weight content, join in a photochemical bleaching reactor Main equipment, adjust the pH value of the reaction system with sodium hydroxide solution to 8-12, add catalyst rose bengal, hydrogen peroxide, and titanium dioxide, the concentration is 0.05-1% of the absolute dry pulp weight content, and place it in the photochemical bleaching The 500W sodium lamp light source in the main equipment is irradiated, and the photochemical bleaching reaction occurs through the catalytic action of the catalyst. The reaction temperature is 30°C, and the bleaching reaction time is 8 hours. After the reaction, the residual lignin in the pulp is removed to obtain the required whiteness. , and then get bleached standby pulp after washing.

Embodiment 2

[0038] Embodiment 2, after paper pulp is dispersed, add water to make the suspension of 2% concentration, through the 0.05-1% DTPA solution pretreatment of 15-60 minute by absolute dry paper pulp weight content, join the main equipment of a photochemical bleaching reactor , adjust the pH value of the reaction system with lye to be 8-12, add the catalyst phlox red (PH), sulfoaluminum, zinc phthalocyanine and sodium silicate whose concentration is 0.5% of dry pulp weight content, 0.3% Titanium dioxide is irradiated by a 1500W mercury lamp light source placed in the main equipment of photochemical bleaching, and through the catalytic action of the catalyst, a photochemical bleaching reaction occurs. The reaction temperature is 80°C, and the bleaching reaction time is 3 hours. lignin to obtain the desired brightness, and then washed to obtain bleached standby pulp.

Embodiment 3

[0039] Example 3, after the pulp is dispersed, add water to make a suspension with a concentration of 1%, after 15-60 minutes of soaking pretreatment, add it to the main equipment of a photochemical bleaching reactor, and adjust the pH value of the reaction system with calcium hydroxide 8-12, add catalyst eosin (EO), and hydrogen peroxide, titanium dioxide, the concentration is 0.05-1% of absolute dry pulp weight content, through the 800W sodium lamp light source that is placed in the main equipment of photochemical bleaching, through catalyst The photochemical bleaching reaction occurs, the reaction temperature is 20°C, and the bleaching reaction time is 10 hours. After the reaction, the residual lignin in the pulp is removed to obtain the required brightness, and then the bleached pulp is obtained after washing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com