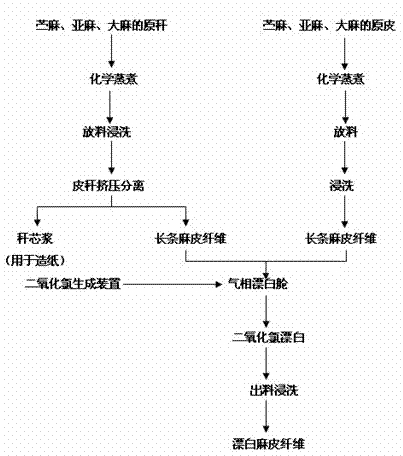

Method for preparing hemp husk fibers through chlorine dioxide gas bleaching

A chlorine dioxide and chlorine dioxide technology is applied in pulp bleaching, fiber raw material processing, cellulose raw material pulping, etc. The effect of reducing energy consumption, increasing strength and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Put the hemp stalks cut into about 1 m into the steaming ball, add the pre-prepared cooking liquid, the solid-liquid ratio is 1:3, and the cooking liquid contains NaOH with 21% dry weight of the hemp stalks and 0.2% anthraquinone, the insufficient amount of water is made up by tap water, and the steamer is closed;

[0043] (2) Rotate the steaming ball idly for 40 minutes, pass in steam to raise the temperature to 160°C, and then keep it warm for 120 minutes, then put the steam in the ball into the dilute black liquor tank and lye tank in the form of small deflation, and start to When the temperature rises, you can also pass in the steaming ball until the steam in the ball is released to the atmospheric pressure, open the steaming ball cover, and rotate the steaming ball to pour the hemp stalks in the ball into the chute;

[0044] (3) Step (2) The hemp stalk poured into the chute enters the pressing area through the wedge-shaped mouth for extrusion and washing. At ro...

Embodiment 2

[0053] (1) Put the raw hemp husks into small bundles into steaming balls, add the pre-prepared cooking liquid, the solid-to-liquid ratio is 1:3.5, and the cooking liquid contains 18% of the dry weight of the hemp husks (NaOH-sodium sulfide mixture), wherein the degree of sulfide is 10%, the volume of added water is 3.5 times the mass of hemp skin, and the insufficient water is made up by the warm and dilute black liquor after pulp washing, and the digester is closed;

[0054] (2) Rotate the steaming ball idly for 20 minutes, pass in steam to raise the temperature to 155°C, and then keep it warm for 210 minutes, then slowly empty the steam in the steaming ball in the form of small deflation, and the exhausted steam is passed into the cooking medicine according to the situation Heating the medicinal solution in the liquid tank or connecting it to other steaming balls to be heated up, so that the temperature in the balls drops below the boiling point of the atmosphere;

[0055] (...

Embodiment 3

[0061] (1) The flax husks separated from the mechanical husks and wrapped into small bundles are put into steaming balls, and the pre-prepared cooking liquid is added. The solid-liquid ratio is 1:4. 17% NaOH by mass and 0.2% hydroanthraquinone by absolute dry mass of hemp skin, the insufficient amount of water is supplemented by warm dilute black liquor or tap water after pulp washing, and a closed digester;

[0062] (2) Steam the ball for 30 minutes in idling motion, feed steam to raise the temperature to 150°C, and then keep it warm for 180 minutes, and the subsequent discharging, black liquor separation and washing operations are the same as steps (2) and (3) of Example 2;

[0063] (3) Subsequent cleaning of the netting frame involved in washing the flax husk, putting on the shelves, closing the bleaching chamber to dehumidify the flax husk, adjusting the dryness of the linseed husk, balancing water, preparation and mixing of the chlorine dioxide preparation liquid, the gene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com