Optical lens for laser two-dimensional linear scanning

An optical lens and linear scanning technology, applied in the field of optical lens, can solve the problems of complex structure and high lens cost, and achieve the effect of simple lens structure, good marking quality and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

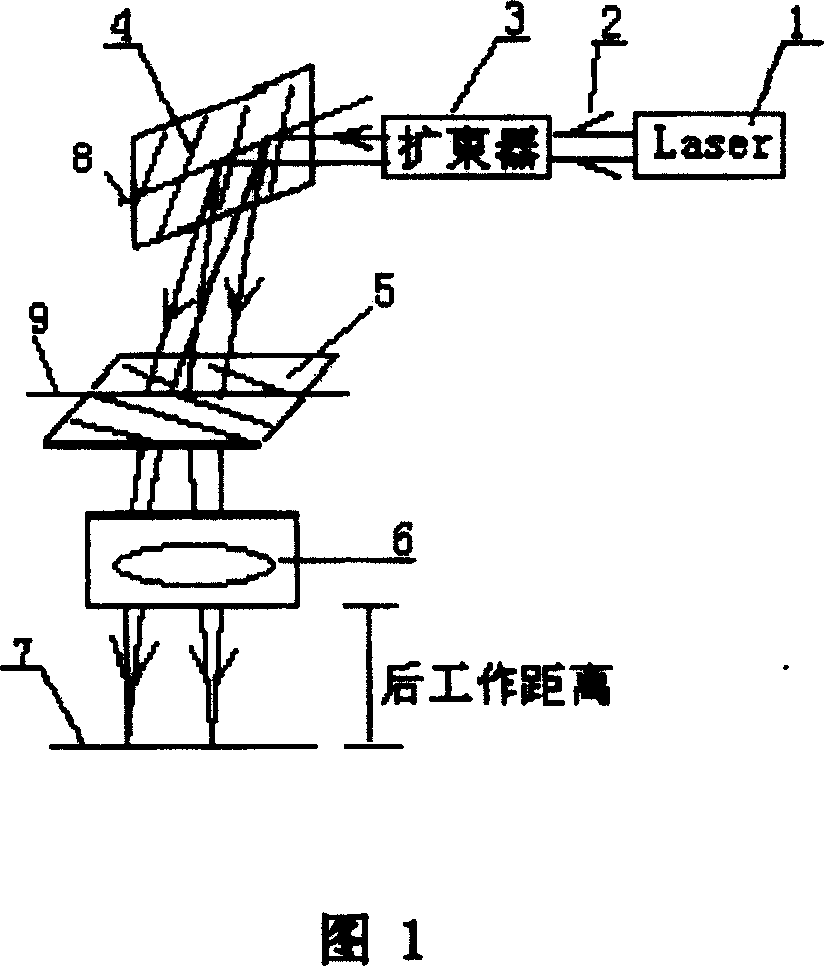

[0022] The technical solution of this embodiment is to provide an f-θ optical lens for a low-inertia vibrating mirror laser marking machine. The laser marking machine uses a YAG laser with a working wavelength of 1.064 μm. The optical system works on this near-infrared monochromatic light. The aperture diaphragm is located outside the optical system, that is, the X-scanning mirror [4] shown in Figure 1.

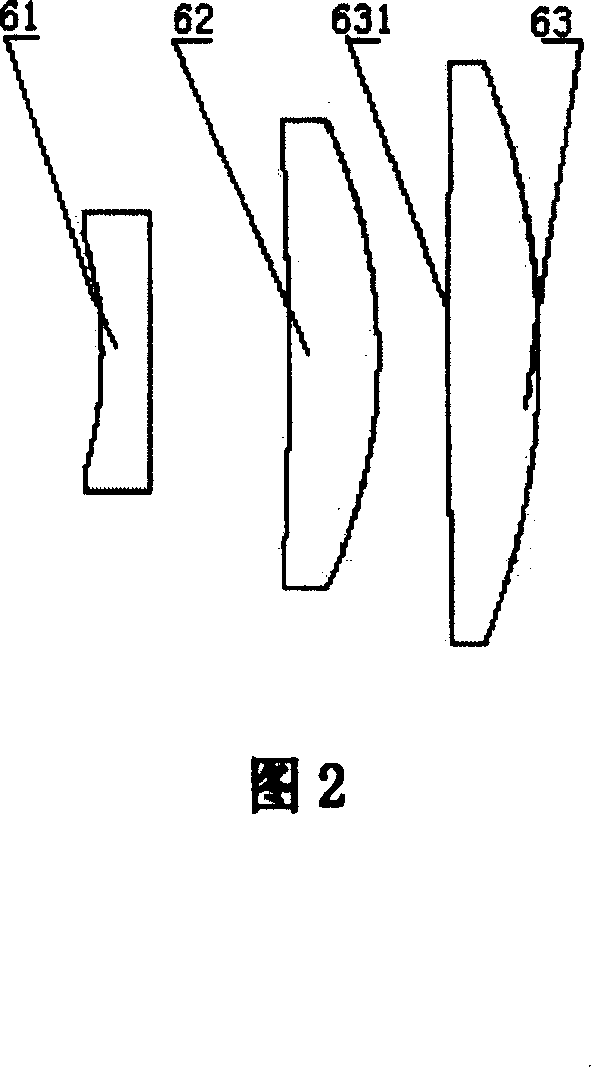

[0023] lens

[0024] The same colorless optical glass is used for the three lens materials, so there is no need to correct for chromatic aberration.

Embodiment 2

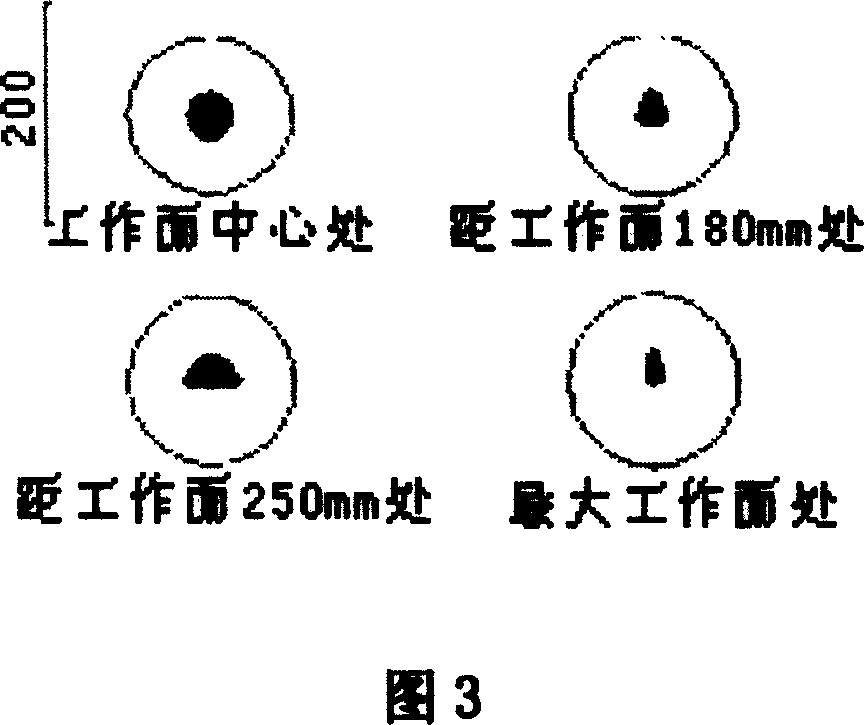

[0027] Referring to accompanying drawing 3, Fig. 3 is the ray tracing spot diagram that light passes through the optical system described in the present embodiment, namely the focusing situation of laser beam on workpiece surface, the circle at each field of view place in Fig. 3 represents Airy spot, by It can be seen that the spot diagrams of each field of view on the image plane fall within the Airy spot, indicating that the optical system has the focusing characteristics of the theoretical limit of diffraction.

[0028] The optical lens distortion curve figure described in the present embodiment is as shown in Figure 4, among the figure, the abscissa is the distortion value (unit %) relative to the f-θ relation, and the ordinate represents the normalized field of view, as seen in Figure 4 , the relative domain change is less than 0.5%, which not only makes the image height and field of view meet the f-θ linear relationship, but also does not affect the marking quality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com