Changing and shaping method for plate strip wave guide laser output laser beam

A technology of waveguide lasers and laser beams, which is applied in the field of lasers and can solve problems such as complex production, poor beam roundness, and large diffraction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

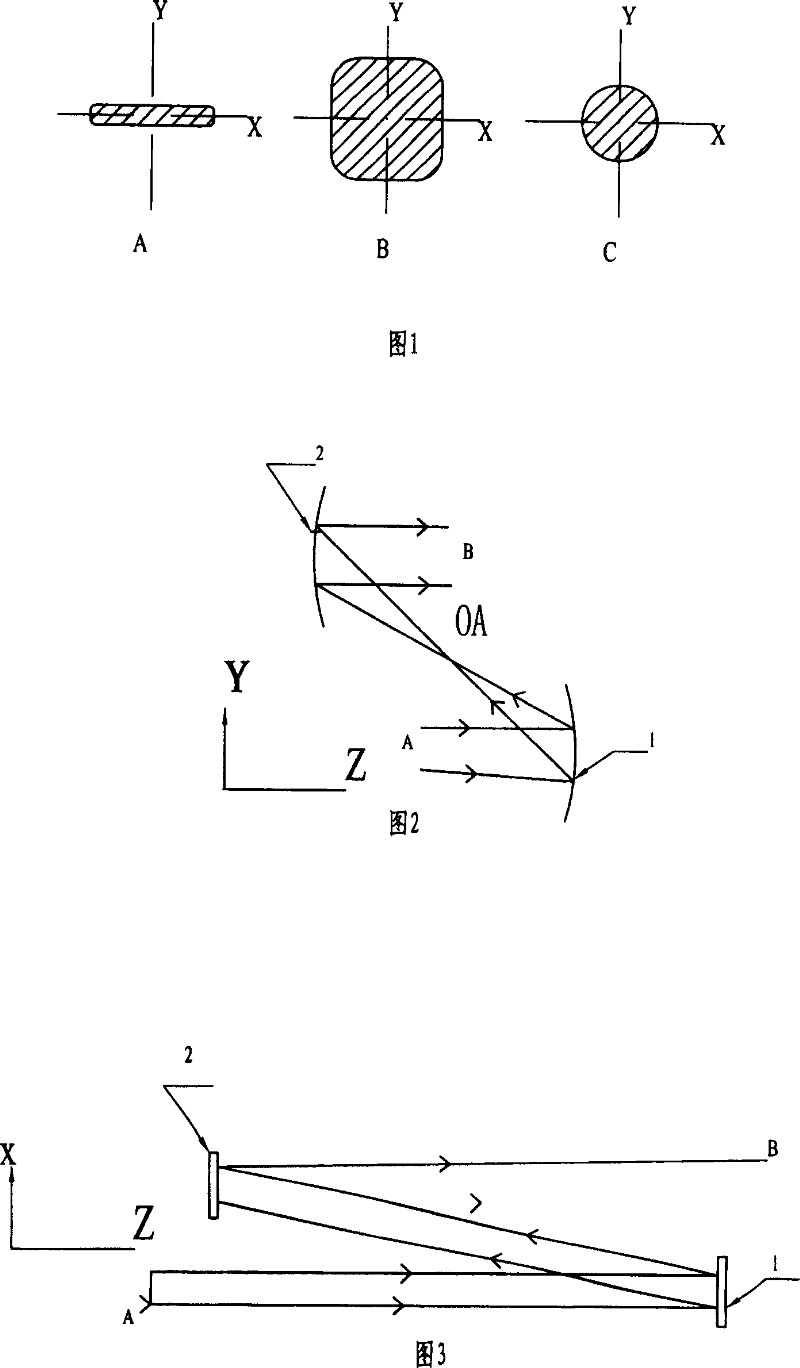

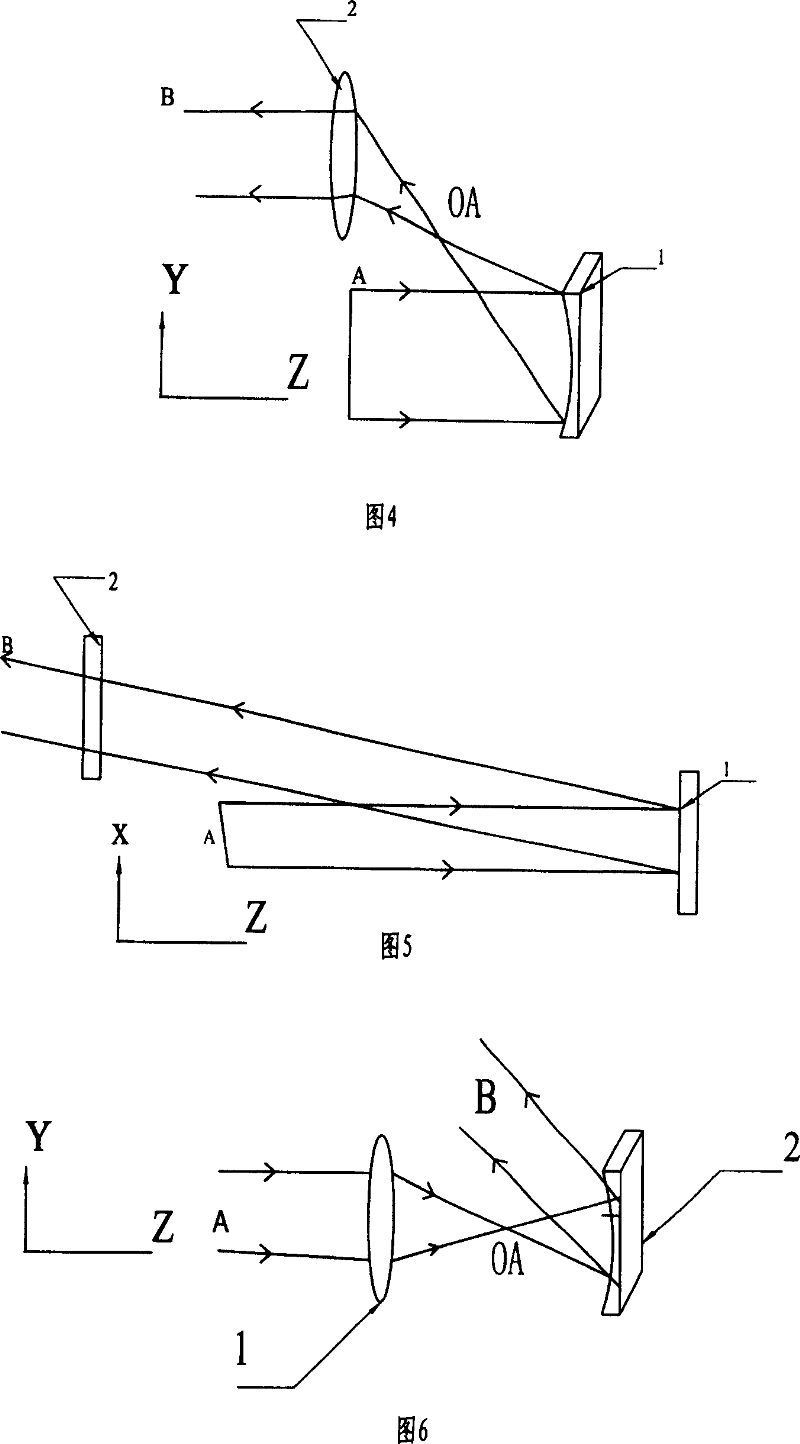

[0070] Diffusion-cooled slab waveguide CO in kilowatt-level RF excitation 2 In the laser, due to the use of an off-axis unstable cavity, it is a quasi-parallel beam output by the unstable cavity in the direction parallel to the slab waveguide (X direction), and a quasi-parallel beam in the direction perpendicular to the slab waveguide (Y direction). Gaussian distributed laser beam, the output laser beam cross section is rectangular at the waveguide port. Quasi-parallel beam radius ω in the direction parallel to the slab waveguide (Y direction) X01 is 12mm, the Gaussian-like laser beam radius ω perpendicular to the slab waveguide direction (Y direction) Y01 is 0.65mm. The output wavelength is 10.6um. The transform shaping process is as follows:

[0071] the focal length f Yc1 The first cylindrical reflector is placed at the waveguide port A at a distance L of 300mm 0 place, L 0 It is 1400mm.

[0072] Calculated according to formulas (2) and (3):

[0073] Y-direction sp...

Embodiment 2

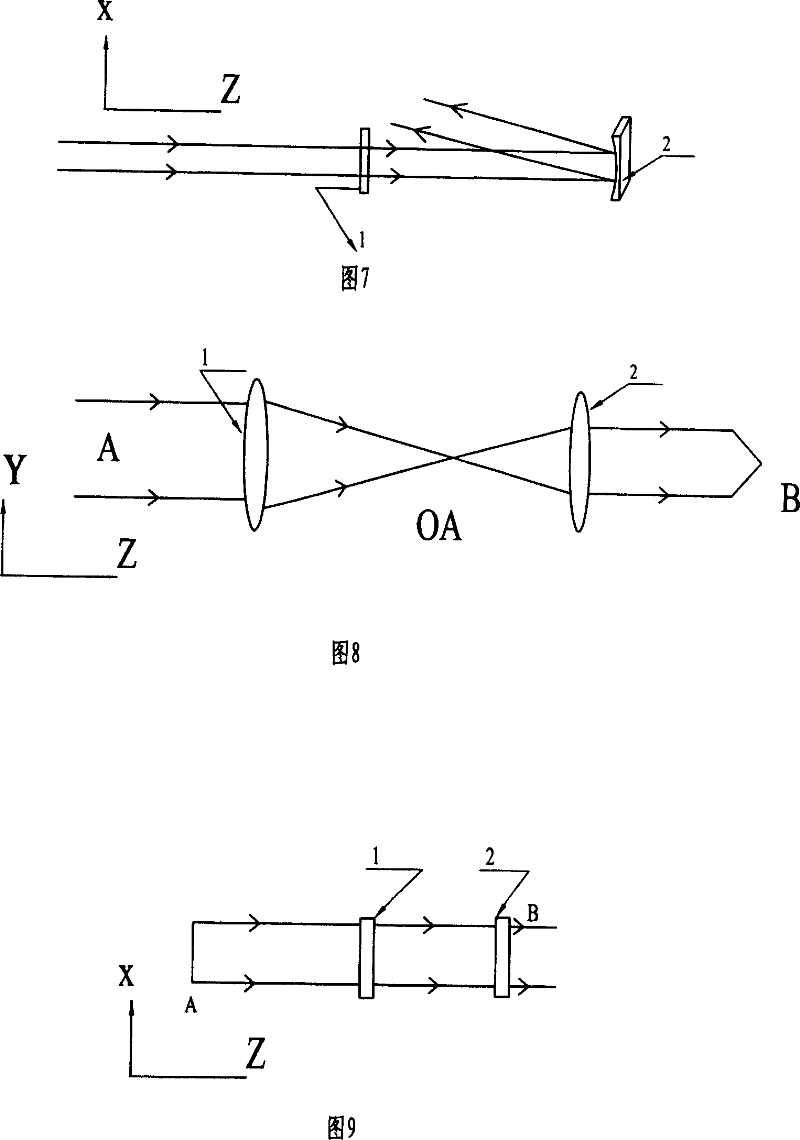

[0077] Slab waveguide CO 2 The output laser beam cross section and transformation shaping method in the laser are the same as in embodiment 1, the difference is that the beam wavelength is 9.6um, and the focal length f Yc1 50mm, L 0 55mm, K 1 =0.5, the focal length of the second cylindrical mirror is f Yc2 lens. The calculation method of the parameters is the same as in Example 1 (see Fig. 4, Fig. 5).

Embodiment 3

[0079] The slab waveguide solid-state laser, the output laser beam and the transformation and shaping method are the same as the embodiment 1, the difference is that the beam wavelength is 1.064um, and the first cylindrical mirror is a lens with a focal length f Yc1 80mm, L 0 500mm, K 1 =2. The calculation method of the parameters is the same as in Example 1. (See Figure 6, Figure 7)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com