Preparation of integrated desulfurizing agent during the two-stage digestible and separating process and its system thereof

A separation process and preparation system technology, applied in the field of slaked lime desulfurization agent preparation, can solve the problems of small particle diameter, blockage of large particles of impurities, excessive floor space, etc., and achieve smooth raw material flow, reduced logistics load, and high surface activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

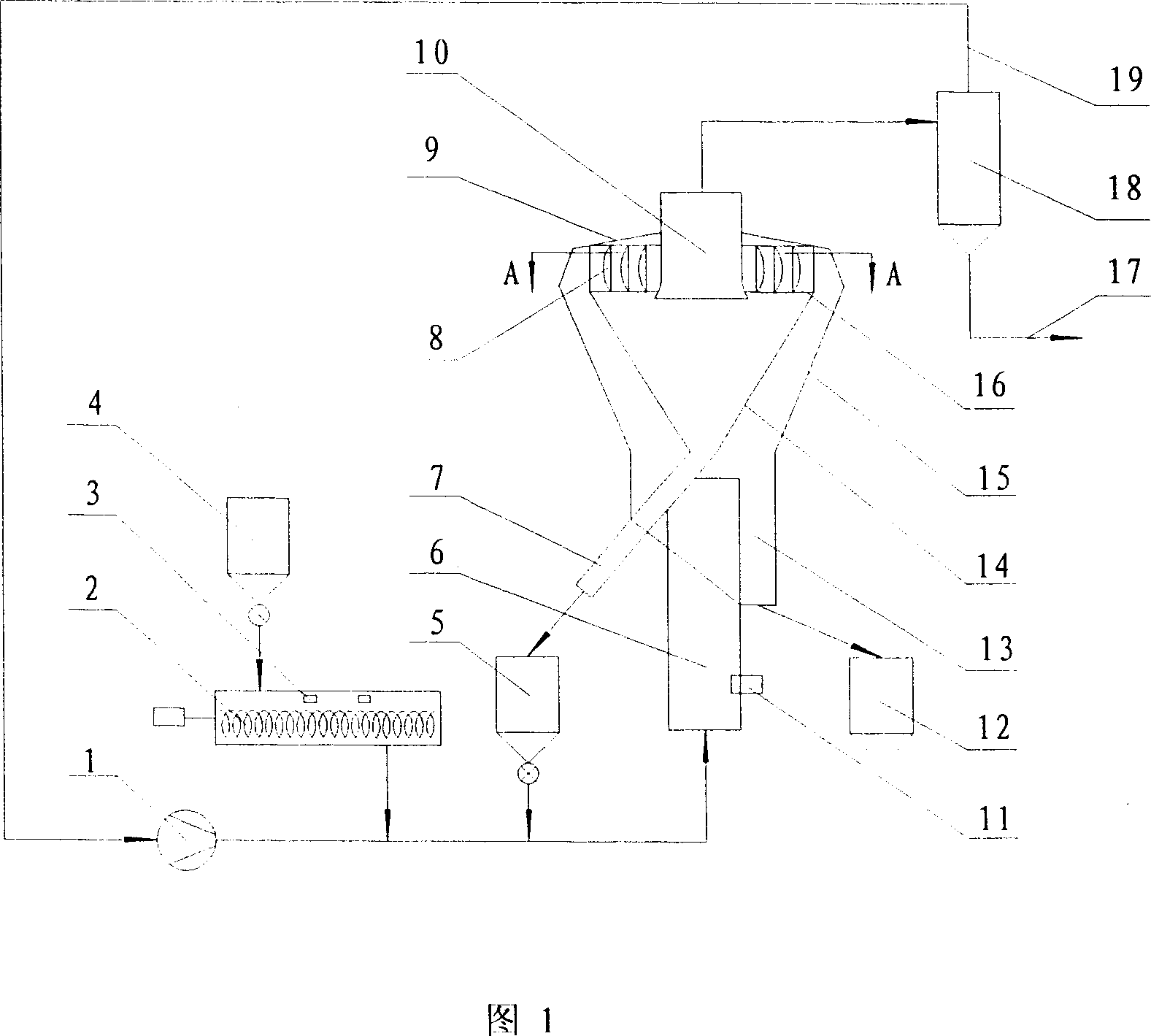

[0028] The desulfurizing agent preparation process of the present invention and its system are further described in detail below in conjunction with the accompanying drawings and specific examples:

[0029]The desulfurizer preparation system integrated with the two-stage digestion and separation process shown in the figure mainly consists of the main body of the digestion reaction tower, the material circulation bin 5 located outside the main body of the digestion reaction tower, the second-stage fine particle separator 18, the spiral stirring digestion Device 2, and fluidization blower 1 composition.

[0030] The feeding port of the spiral stirring digester 2 is connected with the quicklime silo 4, and the top of the spiral stirring digester 2 is provided with atomizing water nozzles 3, and the atomizing water nozzles 3 can be single or arranged in parallel.

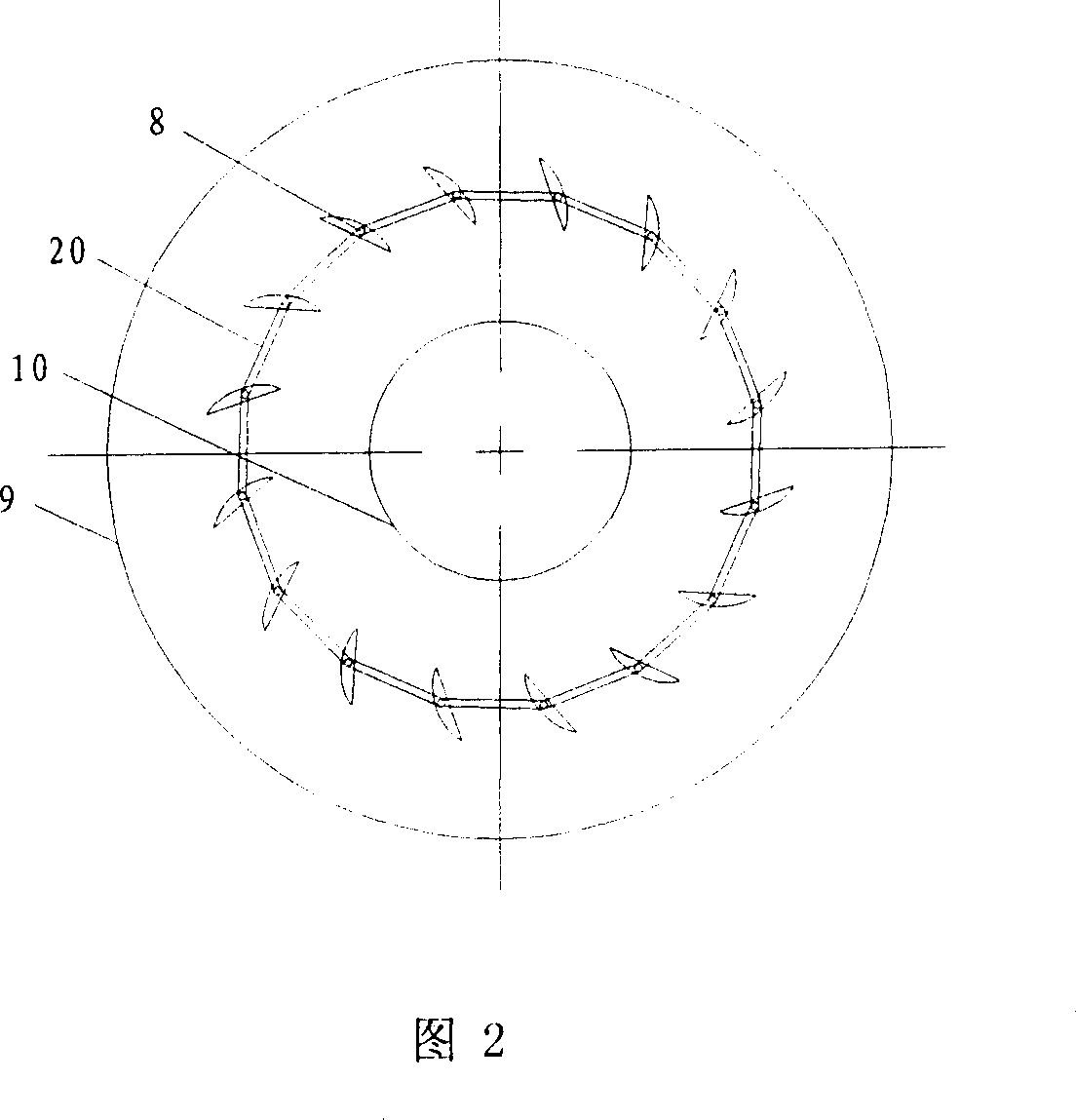

[0031] The main body of the digestion reaction tower includes a cylindrical digestion fluidization section 6 , an ann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com