Quadrupole field emission display and making method thereof

A quadrupole structure and manufacturing method technology, which is applied in cold cathode manufacturing, electrode system manufacturing, non-luminescent electrode manufacturing, etc., can solve the problems of high cost and difficulty in uniform layer thickness, and achieve the effect of increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

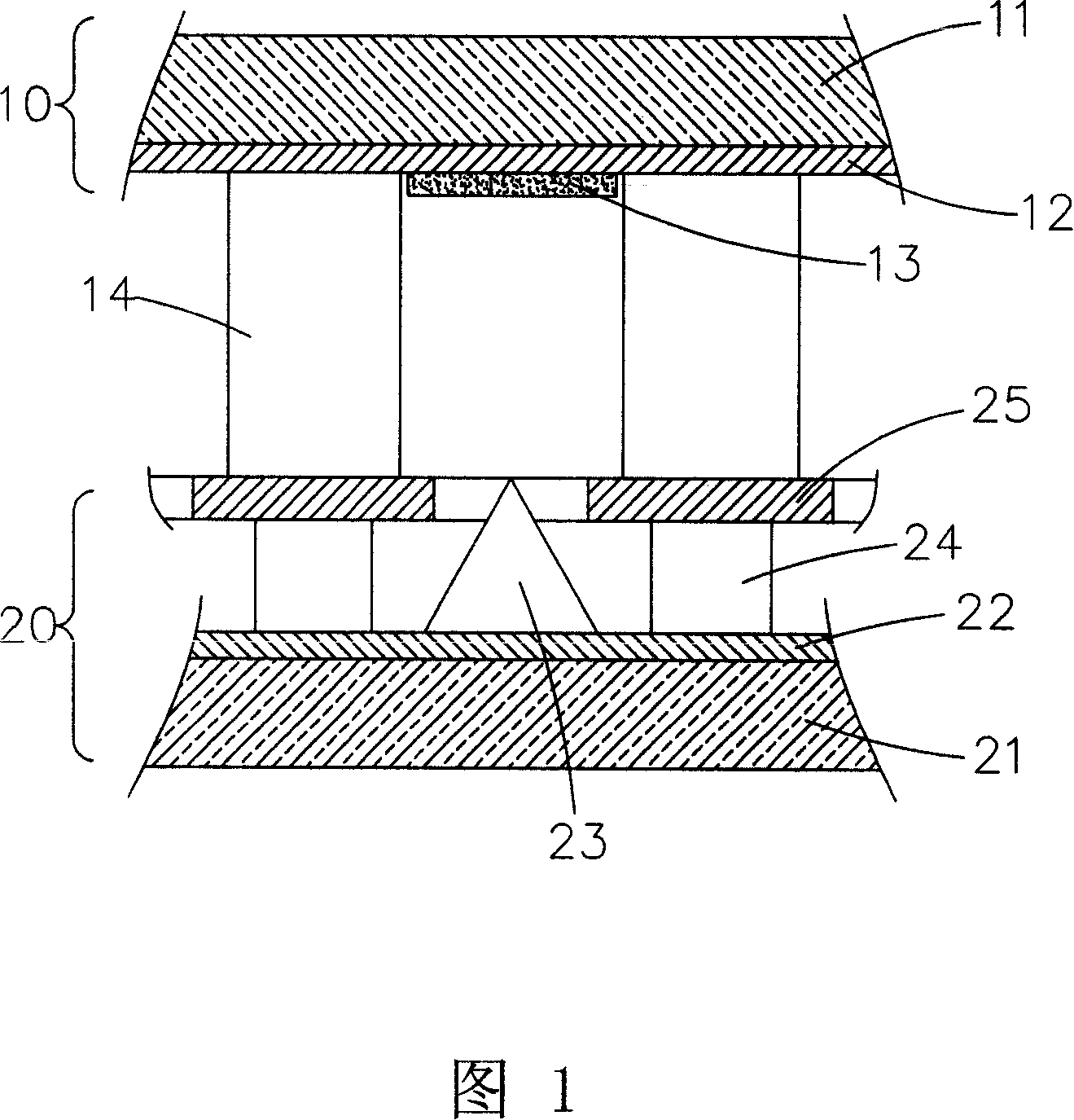

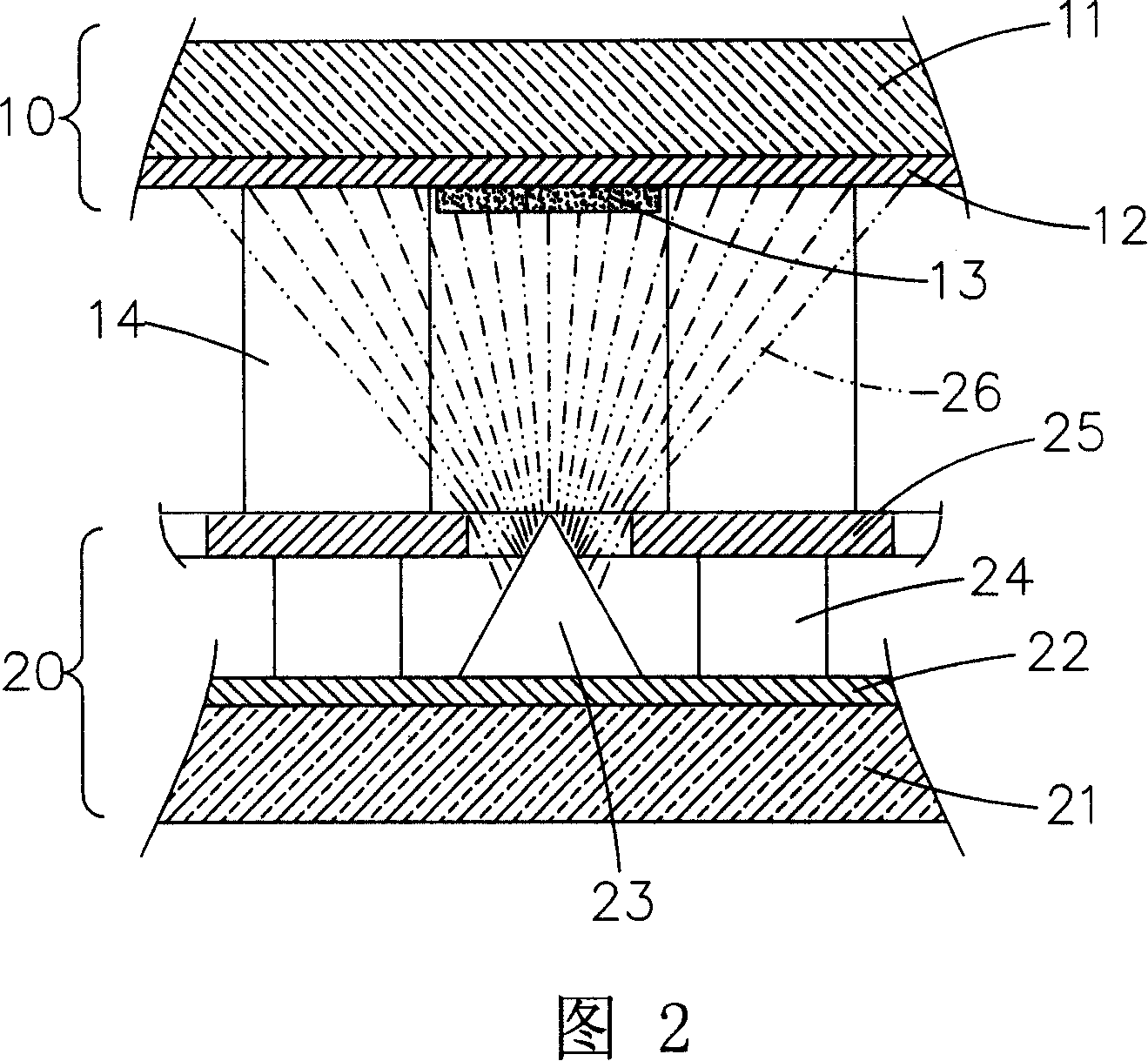

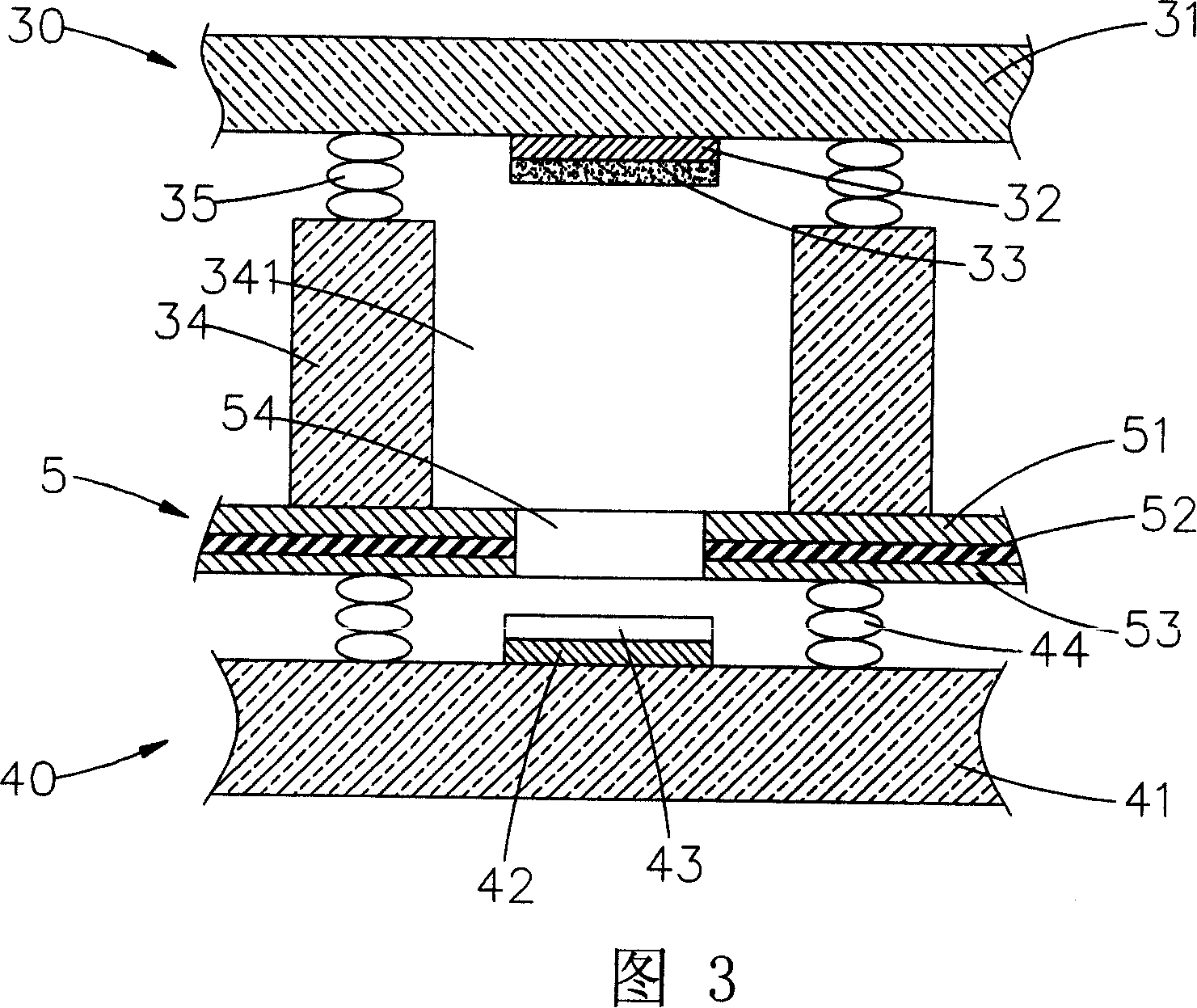

[0049] Fig. 3 is a cross-sectional view of the field emission display of the present invention. It is composed of a set of cathode unit and anode unit. The phosphor layer 33 of each anode unit of the anode plate 30 is attached to the anode conductive layer 32, and the anode conductive layer 32 is attached to the anode substrate 31. The electron source emission layer 43 of each cathode unit of the cathode plate 40 is attached on the cathode conductive layer 42, and the cathode conductive layer 42 is attached on the cathode substrate 41. A mesh cover 5 is fixedly installed between the cathode plate 40 and the anode plate 30. The mesh cover 5 has a three-layer structure of a convergence electrode layer 51, an insulating layer 52 and a gate electrode layer 53. The convergent electrode layer 51 faces the anode plate 30 and the gate layer 53 faces the cathode plate 40. Both the gate layer 53 and the convergence electrode layer 51 have an appropriate potential. A plurality of through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com