Preparation method of AlN Si3N4-SiC ceramic material

A technology for ceramic materials and ceramic bodies, applied in the field of preparation of multiphase ceramic materials, can solve problems such as limited enhancement effect, and achieve the effects of reducing preparation cost, improving sintering performance, and improving interface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

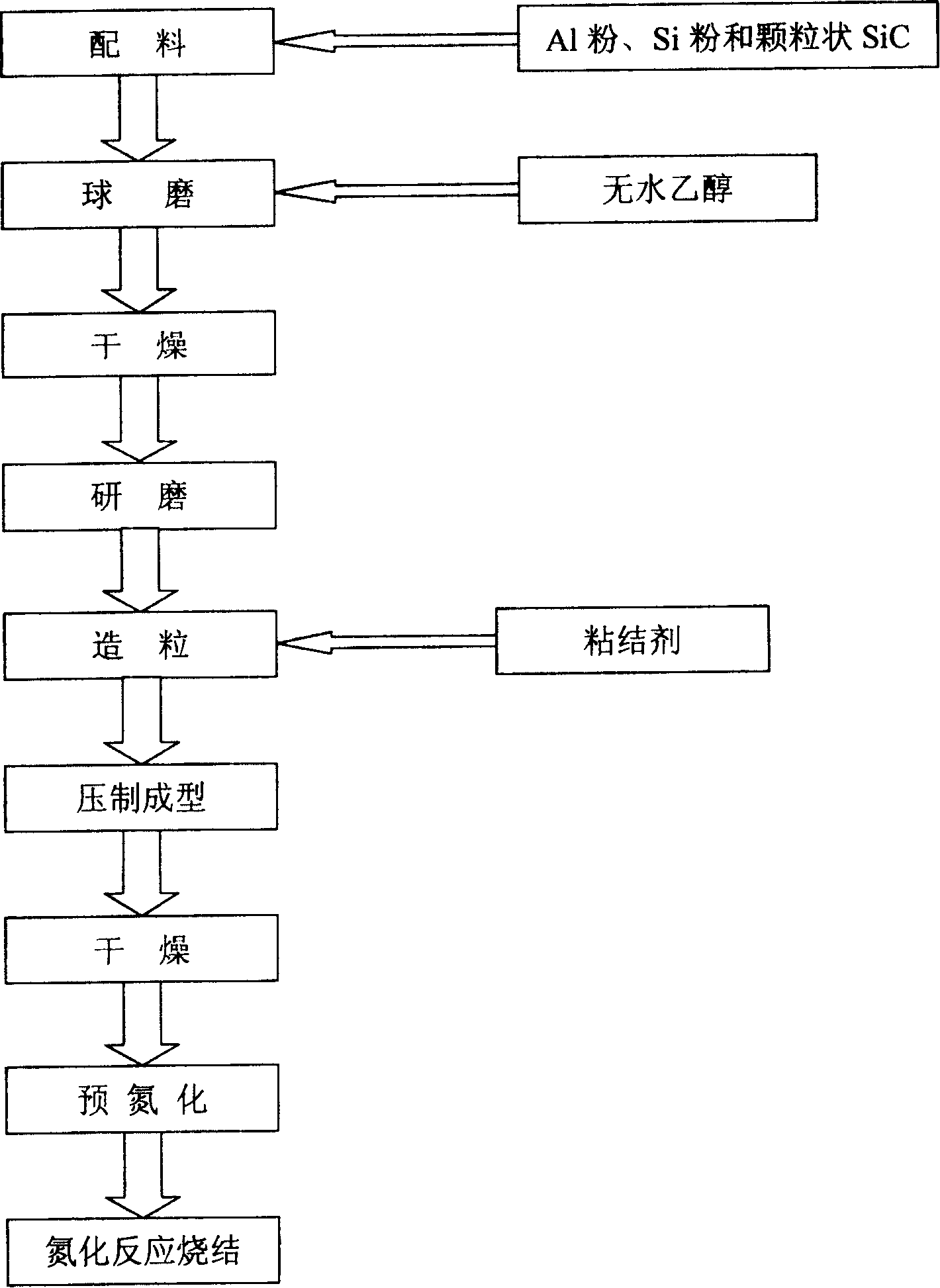

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041] combine figure 1 , the present invention AlN-Si 3 N4 -The preparation method of SiC ceramic material, comprises the following steps:

[0042] 1.1 Prepare Al powder, Si powder and SiC particles in a mass ratio of 2:7:3 as raw materials.

[0043] 1.2 Add the prepared raw materials into absolute ethanol, ball mill in a ball milling tank, the absolute ethanol is submerged in the powder, seal the ball milling tank after the gas is drained, that is, refine and refine the powder by adding absolute ethanol ball milling Mixing, the ratio of material to ball is 1:3, and the ball milling time is 2 hours.

[0044] 1.3 Put the ball-milled powder in the air for a period of time after solid-liquid separation, and then put it into a drying oven for drying. The drying temperature is 80°C, not exceeding 80°C.

[0045] 1.4 Grinding and refining the dried powder.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com