Modified nanometer ZSM-5 molecular sieve catalyst, preparation method and application thereof

A ZSM-5, catalyst technology, applied in the field of modified nano ZSM-5 molecular sieve catalyst and its preparation, can solve the problem of low xylene selectivity, and achieve the effects of prolonging catalyst life, high activity and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The nanometer NaZSM-5 molecular sieve was exchanged with 0.5N ammonium nitrate solution at 80°C for 3 times for sodium ion exchange, each time for 2 hours. Washing with water, drying at 90-120°C, and roasting at 540°C for 5 hours to prepare nanometer HZSM-5 molecular sieve.

[0043] Reaction conditions: HC (HC is the sum of toluene and methanol) weight space velocity 2h -1 ; Toluene / methanol (mol / mol): 2 / 1; Temperature: 410°C; Atmospheric pressure: H 2 / HC (mol / mol): 8.5. The obtained toluene conversion rate was 38.91%, and the p-xylene selectivity was 76.36%.

[0044] Micron HZSM-5 prepared by the same method, under the same reaction conditions, the conversion rate of toluene is 36.43%, and the selectivity of p-xylene is 76.46%.

Embodiment 2

[0046] The nano HZSM-5 molecular sieve prepared in Example 1 was impregnated with a rare earth solution with a mass ratio of molecular sieve to rare earth of 100:25, dried, and roasted to obtain a rare earth modified nano ZSM-5 molecular sieve. For toluene, methanol alkylation reaction.

[0047] Reaction conditions: HC weight space velocity 2h -1 ; Toluene / methanol (mol / mol): 2 / 1; Temperature: 410°C; Atmospheric pressure: H 2 / HC (mol / mol): 8.5. The obtained toluene conversion rate is 32.80%, and the p-xylene selectivity is 76.65%.

Embodiment 3

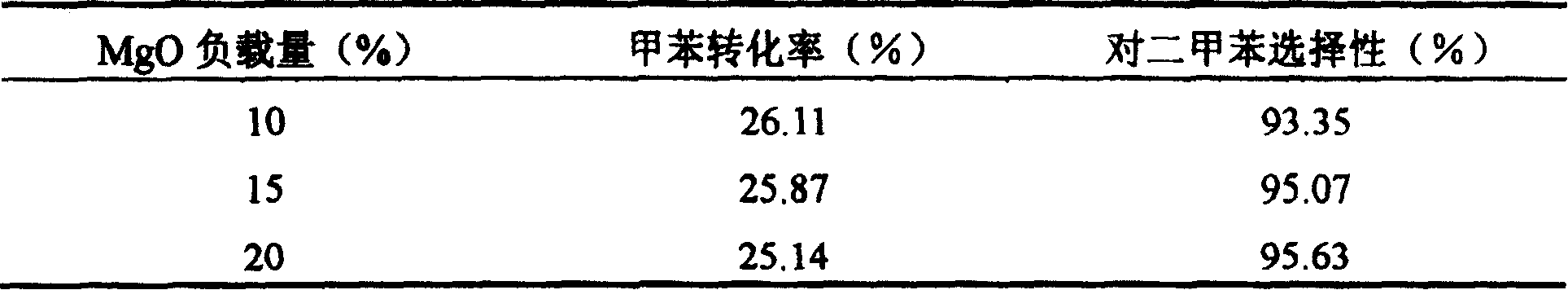

[0049] The rare earth modified nano ZSM-5 molecular sieve prepared in Example 2 was impregnated with magnesium acetate solution at room temperature for 5-15 hours, dried and roasted to obtain modified catalysts loaded with 10%, 15%, and 20% MgO respectively , Tablet molding. The effect of different MgO loadings on the catalyst performance was investigated.

[0050] Reaction conditions: HC weight space velocity 2h -1 ; Toluene / methanol (mol / mol): 2 / 1; Temperature: 410°C; Atmospheric pressure: H 2 / HC (mol / mol): 8.5. The reaction results showed that as the MgO loading increased from 10% to 20%, the toluene conversion rate was 26.11-25.14%, and the p-xylene selectivity was 93.35-95.63% (see Table 1).

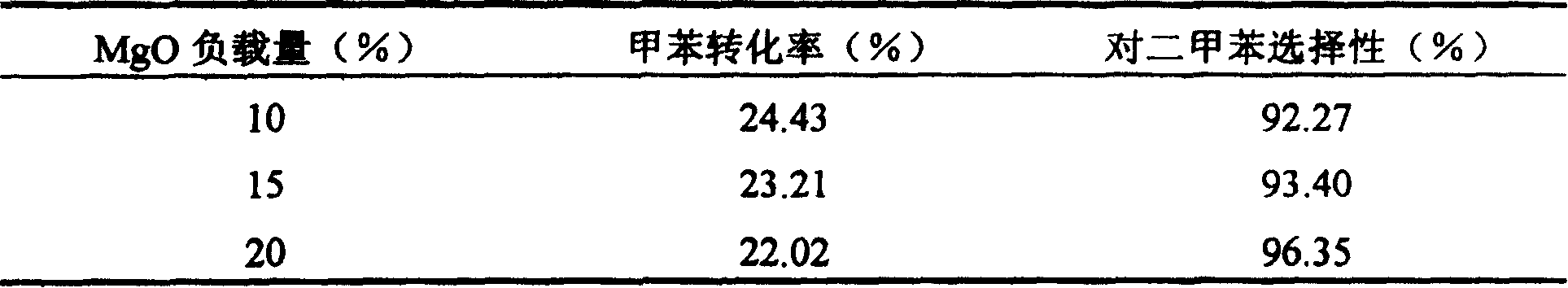

[0051] In the same way, modified micron ZSM-5 catalysts loaded with 10%, 15%, and 20% MgO were prepared respectively. Under the same reaction conditions, the reaction results were as follows: as the MgO loading increased from 10% to 20%, the toluene conversion The rate is 24.43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com