Making process of pattern on wafer and its application

A technology of an integrated circuit and a manufacturing method, which is applied to the field of manufacturing integrated circuit patterns on a wafer, can solve the problems of difficult process control, low production efficiency, cracks, etc., and achieves the effects of simple equipment, low cost, and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A disc with a central hole is made of good light-transmitting glass, and the size is consistent with a 120mm disc. A layer of chrome is plated on the surface of the glass disc, and then the glass disc is coated with photosensitive adhesive to make a recordable disc; Use a disc recorder to record the pattern that needs to be etched on the silicon dioxide film on the wafer on the glass disc. The light source in the disc recorder is a laser with a wavelength of 650nm; then develop the patterned glass disc to make a mask; A mask plate for metal aluminum wiring is produced by the method. Then put the glass wafer mask plate corresponding to the etching pattern of the silicon dioxide film layer on the silicon wafer coated with photosensitive adhesive through oxidation, and use the light source to irradiate and expose the area determined by the mask plate, and then place the silicon wafer on the Develop in the developer; then etch the silicon wafer, and then remove the hardened...

Embodiment 2

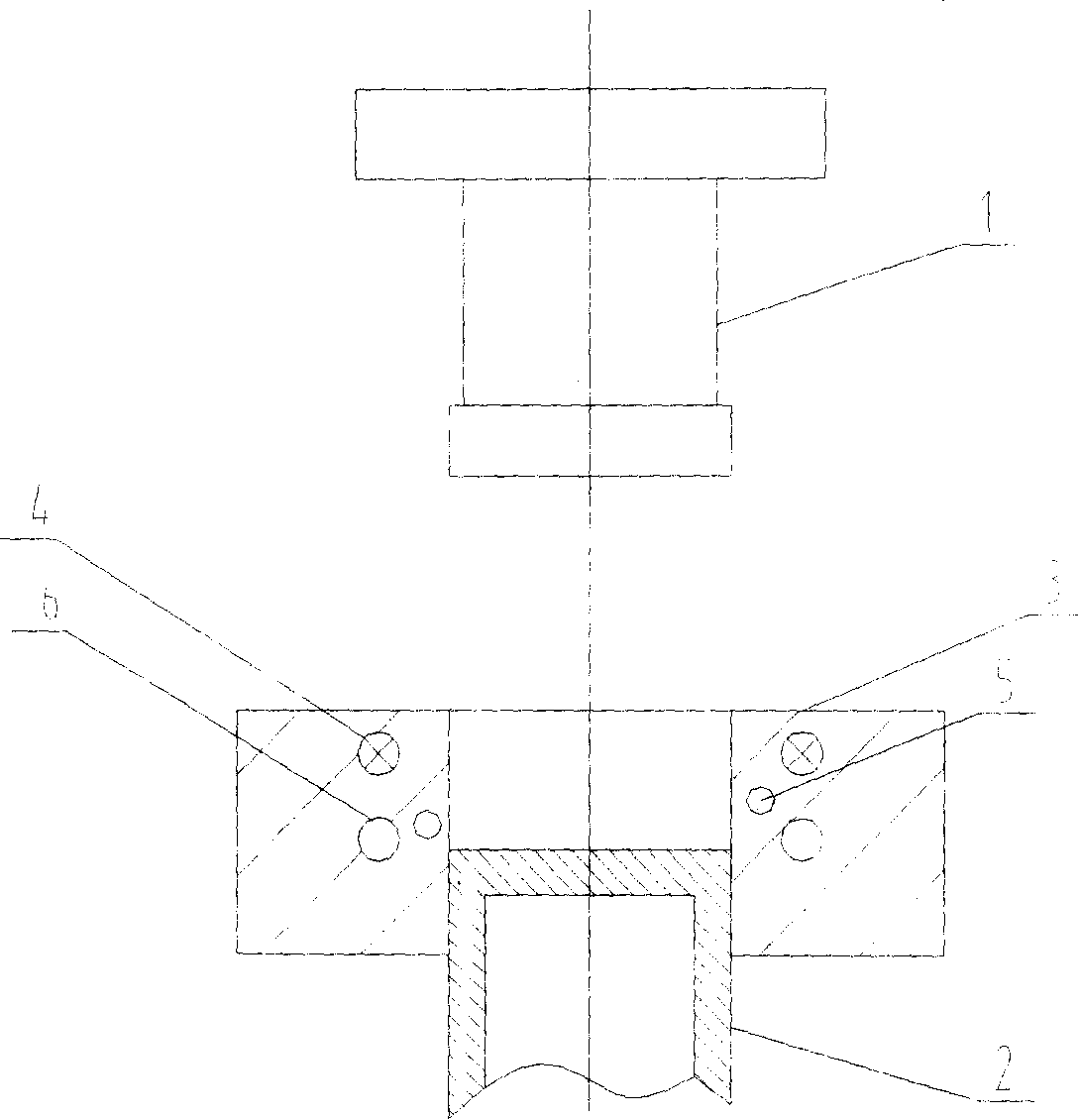

[0024] first use figure 1 The mold shown is used to shape the desired silicon wafer. Such as figure 1 As shown, the male mold 1 and the male mold 2 are placed in the female mold 3, and the heating element 4 is energized to preheat the mold, and the thermocouple 5 can collect the temperature on the female mold 3. After reaching the set temperature, the male mold 1 is removed from the The female mold 3 exits upwards, and the male mold 2 stays at the bottom of the female mold 3. Liquid silicon is poured into the female mold 3. The superheated temperature of the liquid silicon is 1500°C, and it will not solidify immediately when poured into the female mold 3. The positive mold 1 is then pressed against the liquid silicon. According to the temperature collected by the temperature acquisition sensor, it is judged whether to pass water through the cooling pipe 6 to cool the female mold 3 or to energize the heating element 4 to heat the female mold 3, so as to ensure that the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com