Substrate cleaning apparatus and method

A technology for cleaning devices and substrates, applied to discharge tubes, electrical components, plasma, etc., can solve problems such as over-etching, and achieve the effect of preventing electrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

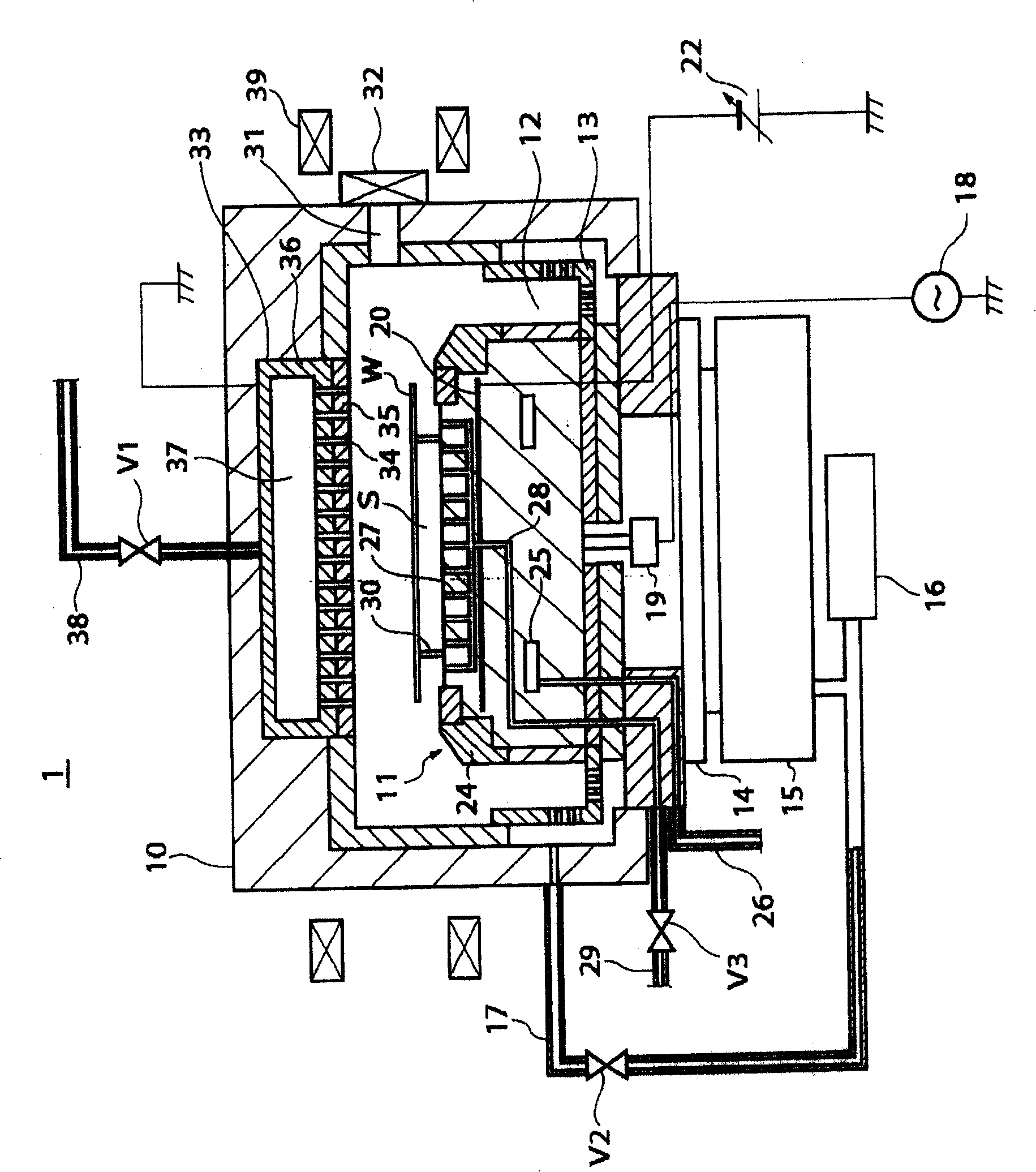

[0124] Next, examples of the present invention will be specifically described.

[0125] The following examples are carried out in the plasma processing apparatus 1 described above.

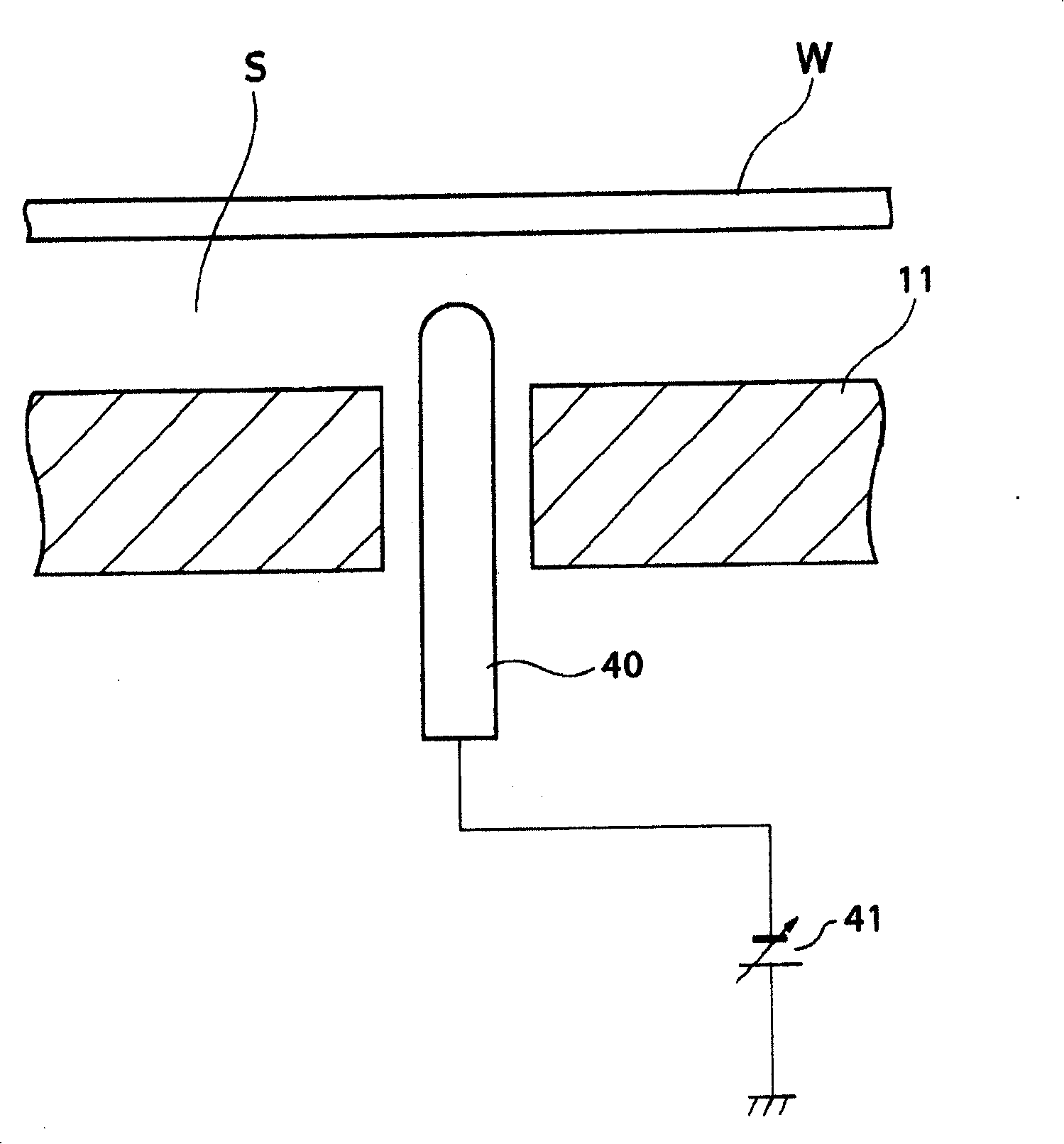

[0126] First, a wafer W on which a large amount of particles adheres to the back surface is prepared, and the wafer W is placed on the ejector pins 30 protruding from the susceptor 11 in the chamber 10 .

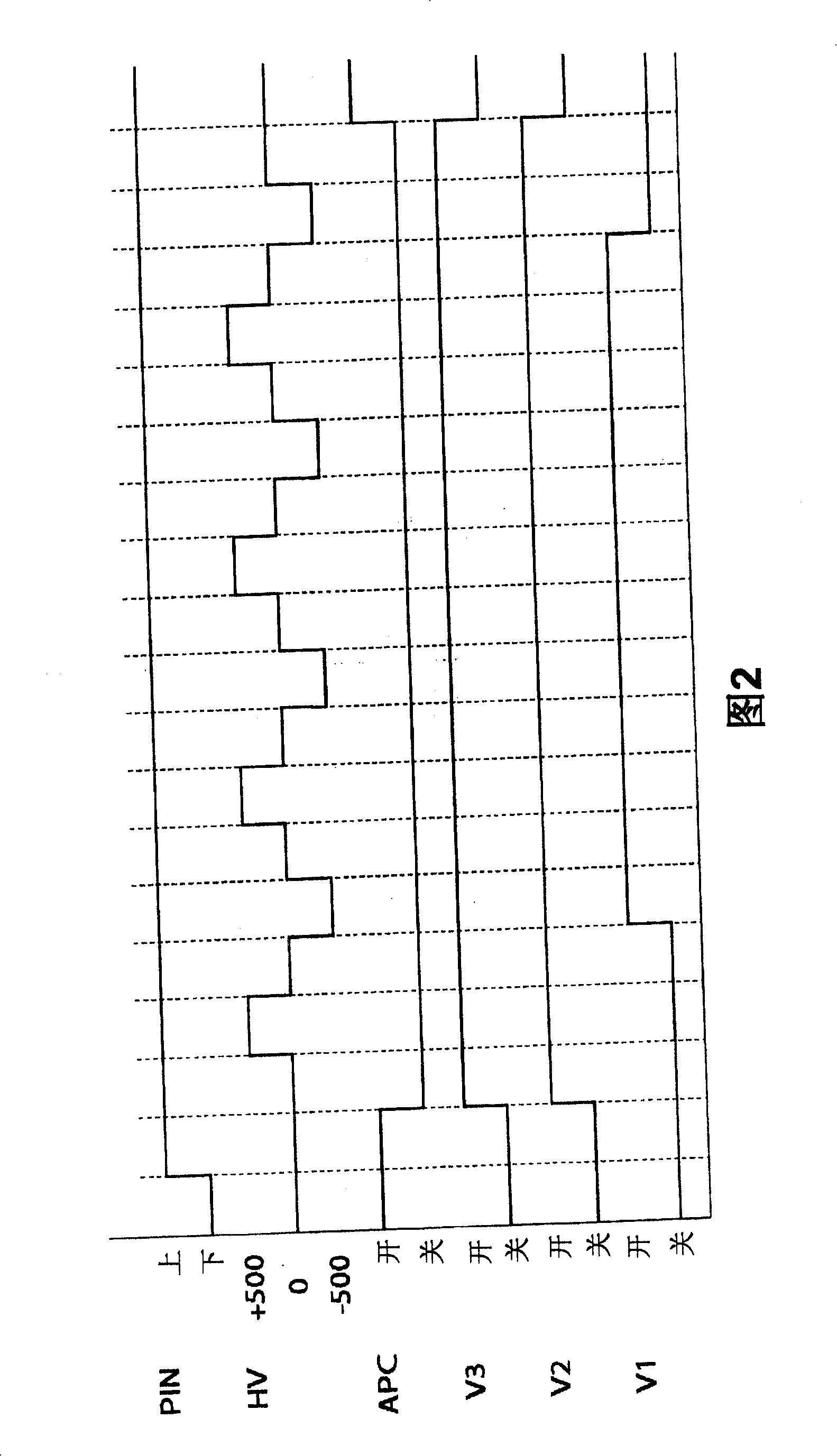

[0127] Then, after the chamber 10 is depressurized by the main discharge line, the APC 14 is closed, and the valve V2 of the exhaust pipe 17 and the valve V3 of the heat transfer gas supply pipe 29 are opened to stably exhaust the chamber 10. While feeding N from the heat transfer gas supply hole 27 2 The gas is ejected toward the back surface of the wafer W. As shown in FIG. Thereby, while keeping the inside of the chamber 10 at 6.65×10 3 Pa (50 torr) or more, while generating a viscous flow in the space S.

[0128] Next, open valve V1 with a flow rate of 7.0×10 4 SCCM put N 2 Gas is intr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com