Preparation method of composite cladding material and equipment

A composite coating and composite plating technology, applied in coatings, electrolytic coatings, cells, etc., can solve the problems of uneven distribution, low percentage of non-metallic particles, low yield, etc., to increase uniformity and improve cladding strength. , the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Cut the plated workpiece 5 of the base pure copper plate into a size of 500*700mm, and perform electrodeposition according to the following steps:

[0019] The following ingredients are configured into composite plating solution 2:

[0020] NiSO 4 ·6H 2 O 250g / L

[0021] NiCl 2 ·6H 2 O 45g / L

[0022] h 3 BO 3 30g / L

[0023] Sodium Gluconate 100g / L

[0024] Surfactant-JFC 2ml / L

[0025] Al 2 o 3 Powder (particle size≤5μm) 80g / L

[0026] ① Soak the pure copper plate in 5% sulfuric acid solution and activate it at room temperature for 1 min;

[0027] ②Clean, then install the hanger and put it into the electrolytic cell 1;

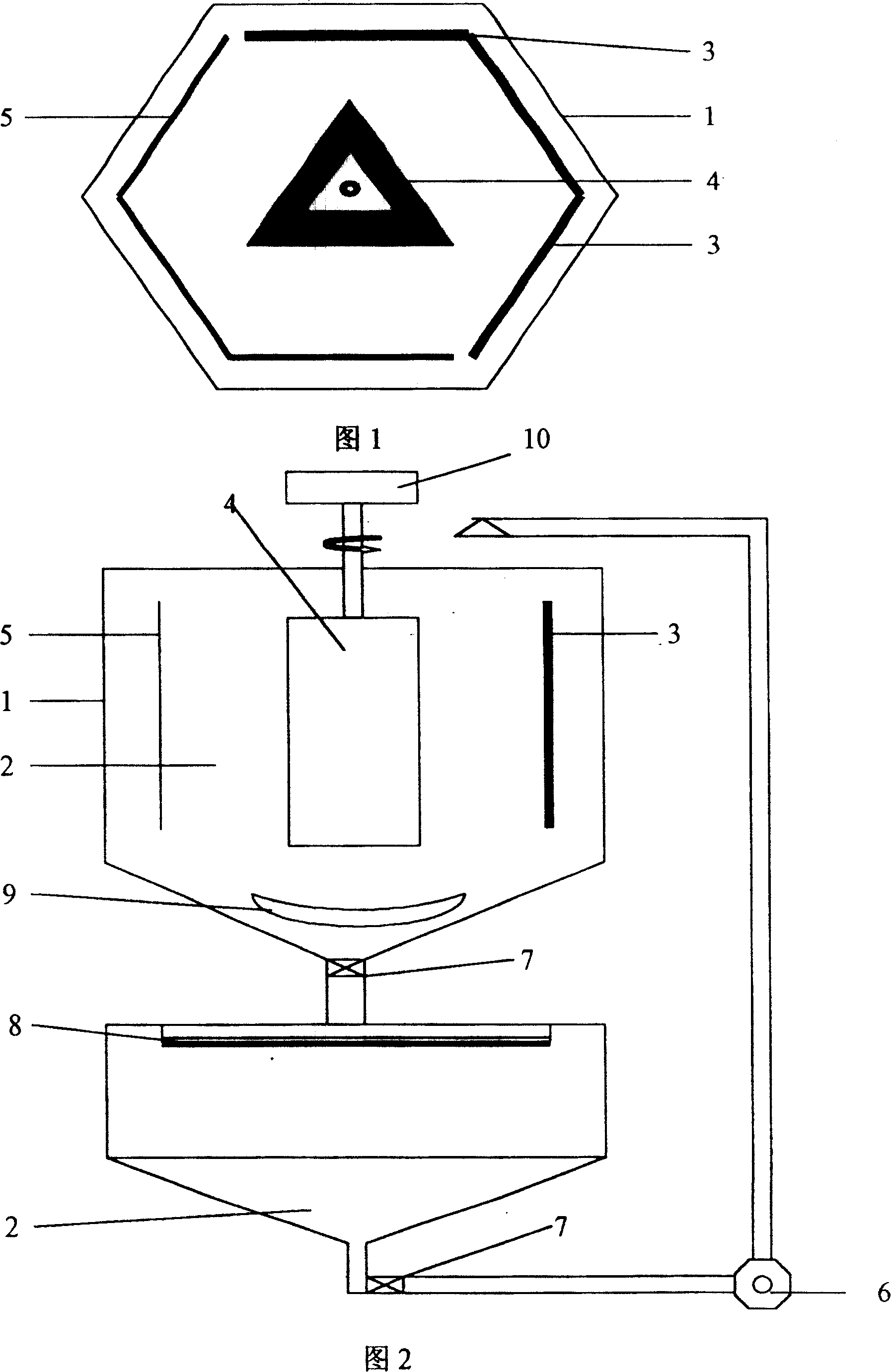

[0028] ③ Turn on the rotating device 10 to rotate the rotating anode 4, turn on the air agitator 9, and pass the pump

[0029] 6 The plating solution can be circulated, and the experiment can be carried out in the electrolytic tank. The parameters of the electroplating process are as follows:

[0030] pH 4.5

[003...

Embodiment 2

[0038] Cut the plated workpiece 5 of the base pure copper plate into a size of 500*700mm, and perform electrodeposition according to the following steps

[0039] The following ingredients are configured into composite plating solution 2:

[0040] NiSO 4 ·6H 2 O 250g / L

[0041] NiCl 2 ·6H 2 O 45g / L

[0042] h 3 BO 3 30g / L

[0043] Sodium Gluconate 100g / L

[0044] TiO 2 Powder (particle size≤5μm) 80g / L

[0045] Surfactant-JFC 2ml / L

[0046] ① Soak the pure copper plate in 5% sulfuric acid solution and activate it at room temperature for 1 min;

[0047] ②Clean, then install the hanger and put it into the electrolytic cell 1;

[0048] ③ Turn on the rotating device 10 to rotate the rotating anode 4, turn on the air agitator 9, and pass the pump 6

[0049] The plating solution can be circulated and experimented in the electrolytic tank. The electroplating process parameters are as follows:

[0050] pH 4.5

[0051] Temperature (°C) 50°C

[0052] ...

Embodiment 3

[0058] Cut the plated workpiece 5 of the base pure copper plate into a size of 500*700mm, and perform electrodeposition according to the following steps:

[0059] The following ingredients are configured into composite plating solution 2:

[0060] NiSO 4 ·6H 2 O 250g / L

[0061] NiCl 2 ·6H 2 O 45g / L

[0062] h 3 BO 3 30g / L

[0063] Sodium Gluconate 100g / L

[0064] SiC powder (particle size≤5mm) 80g / L

[0065] Surfactant-JFC 2ml / L

[0066] ① Soak the pure copper plate in 5% sulfuric acid solution and activate it at room temperature for 1 min;

[0067] ②Clean, then install the hanger and put it into the electrolytic cell 1;

[0068] ③ Turn on the rotating device 10 to rotate the rotating anode 4, turn on the air agitator 9, and pass the pump 6

[0069] The plating solution can be circulated and experimented in the electrolytic tank. The electroplating process parameters are as follows:

[0070] pH 4.5

[0071]Temperature (°C) 50°C

[0072] Curr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com