Preparation method of flow liner crystallite glass

A glass-ceramic and flow pattern technology, which is applied in glass pressing, glass manufacturing equipment, glass forming, etc., can solve the problems of texture morphology and color matching and decoration effect, difficult to generate texture and pattern, and blurred pattern. , to achieve the effect of inhibiting ecological environment damage, natural decorative effect, and overcoming poor overall feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

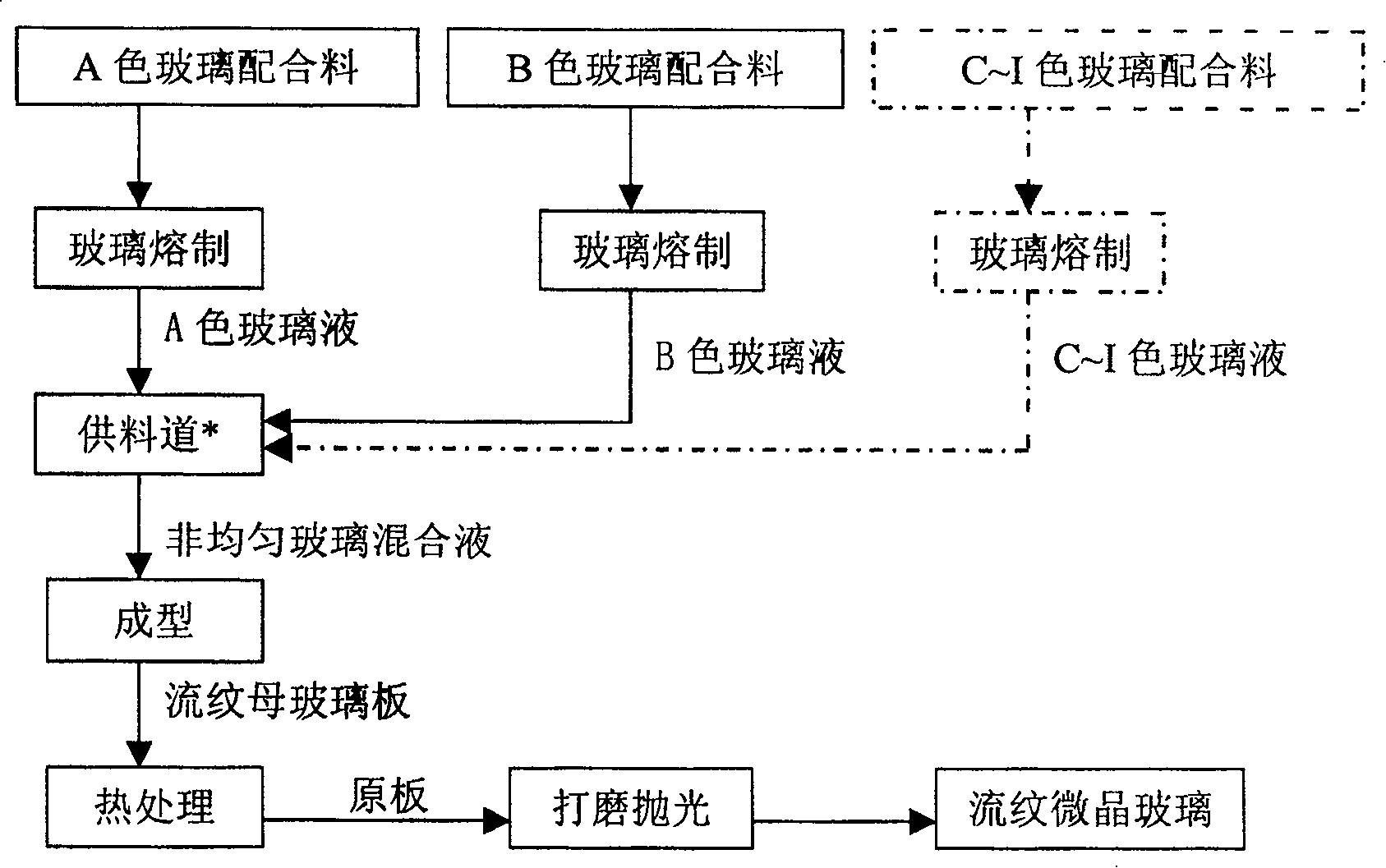

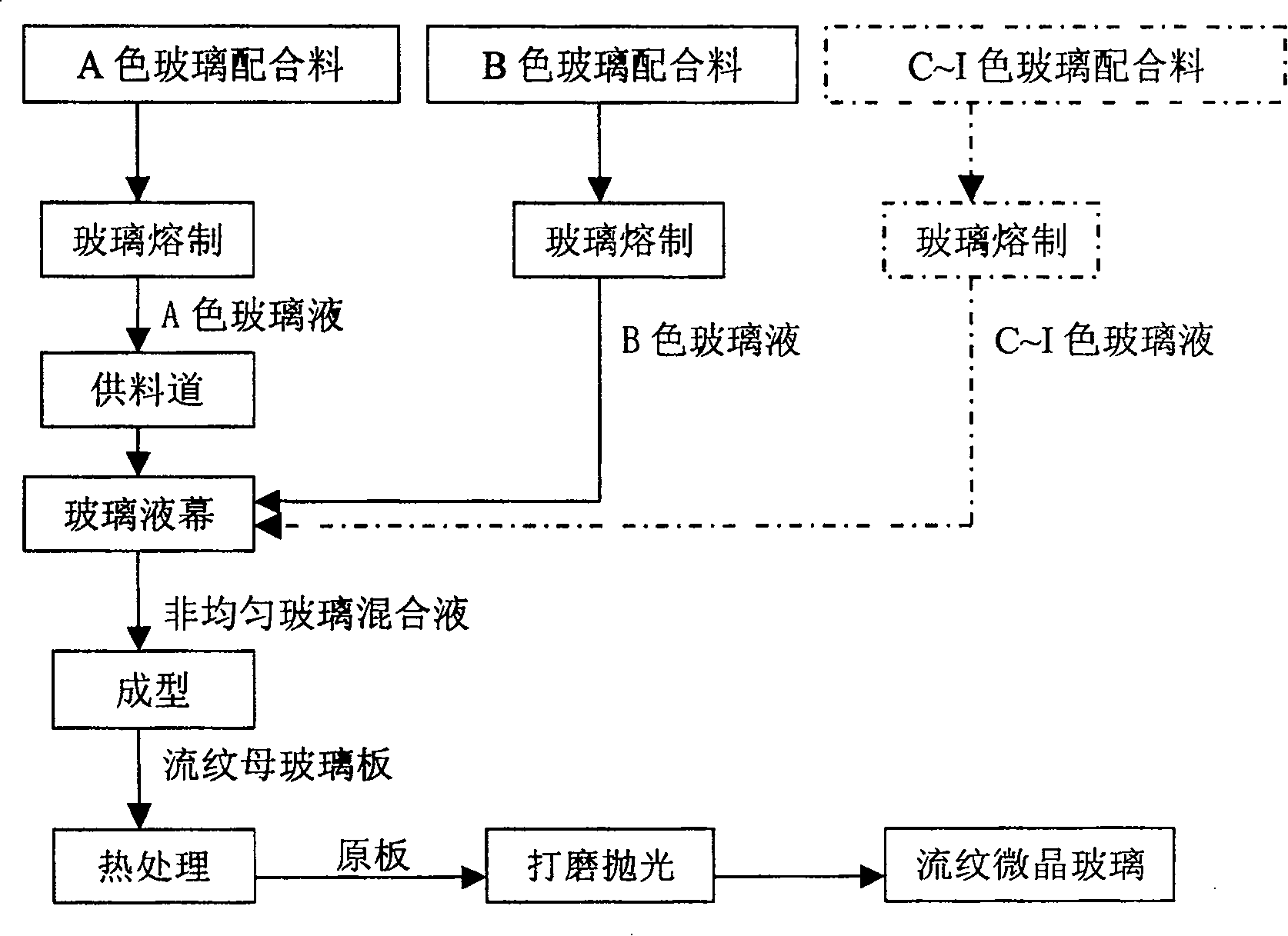

[0021] As shown in Fig. 1(a), the preparation method of rhyolite glass ceramics includes the following steps:

[0022] (1) Melting of two colors (A color and B color) of molten glass: Weigh and prepare the green and yellow glass batches respectively, and the mass percentage of the main chemical components of the green glass batch is: 56.0% SiO 2 , 9.0% Al 2 O 3 , 21.0%CaO, 2.0%MgO, 2.0%K 2 O, 4.5%Na 2 O, 0.5% Sb 2 O 3 , 0.3% TFe 2 O 3 , 0.7% Cr 2 O 3 , 4.0% ZrO 2 , The mass percentage of the main chemical composition of the yellow glass batch is: 56.0% SiO 2 , 8.0% Al 2 O 3 , 21.0%CaO, 2.0%MgO, 2.0%K 2 O, 4.5%Na 2 O, 0.5% Sb 2 O 3 , 0.8%TFe 2 O 3 , 4.0% ZrO 2 , 1.2% MnO 2 . Put the glass batches of the two colors into two glass melting furnaces respectively, keep them at 1500℃ for 2h, and melt them into two kinds of glass liquids of different colors;

[0023] (2) Inhomogeneous mixing of molten glass: Lead the molten green glass into the forehearth of the melting furnace for meltin...

Embodiment 2

[0028] As shown in Fig. 1(a), the preparation method of rhyolite glass ceramics includes the following steps:

[0029] (1) Melting of two colors (A color and B color) of molten glass: same as Example 1;

[0030] (2) Inhomogeneous mixing of molten glass: Lead the molten green glass into the forehearth of the melting furnace for melting yellow glass near one end of the cooling part of the furnace (the dosage ratio between the molten green glass and the molten yellow glass is 1:2), Stirring equipment is set in the feeding channel to stir the glass confluent liquid at a speed of 8r / min, so that the two glass liquids of different colors can be mixed to a certain extent, and a non-uniform glass mixed liquid with a higher degree of mixing is produced;

[0031] (3) Forming: same as Example 1;

[0032](4) Heat treatment: same as Example 1;

[0033] (5) Finishing: cutting, grinding, and polishing the original glass-ceramic plate to obtain a delicate, turbulent flow-shaped glass-ceramic with...

Embodiment 3

[0035] As shown in Fig. 1(a), the preparation method of rhyolite glass ceramics includes the following steps:

[0036] (1) Melting of two colors (A color and B color) of molten glass: same as Example 1;

[0037] (2) Inhomogeneous mixing of molten glass: the yellow molten glass is introduced into the forehearth of the melting furnace for melting green glass near one end of the outlet of the melting furnace (the dosage ratio between the yellow molten glass and the green molten glass is 1:2) , The yellow and green two glass liquids merge with each other when they flow out through the discharge port, forming a non-uniform glass mixed liquid with a very low degree of mixing;

[0038] (3) Forming: same as Example 1;

[0039] (4) Heat treatment: same as Example 1;

[0040] (5) Finishing: cutting, grinding, and polishing the original glass-ceramic plate to obtain a streamlined flow-shaped glass-ceramic with a combination of yellow and green.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com