Characterization emthod for convertable phase change material electric property

A technology of phase change materials and electrical properties, applied in electrical components, static memory, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

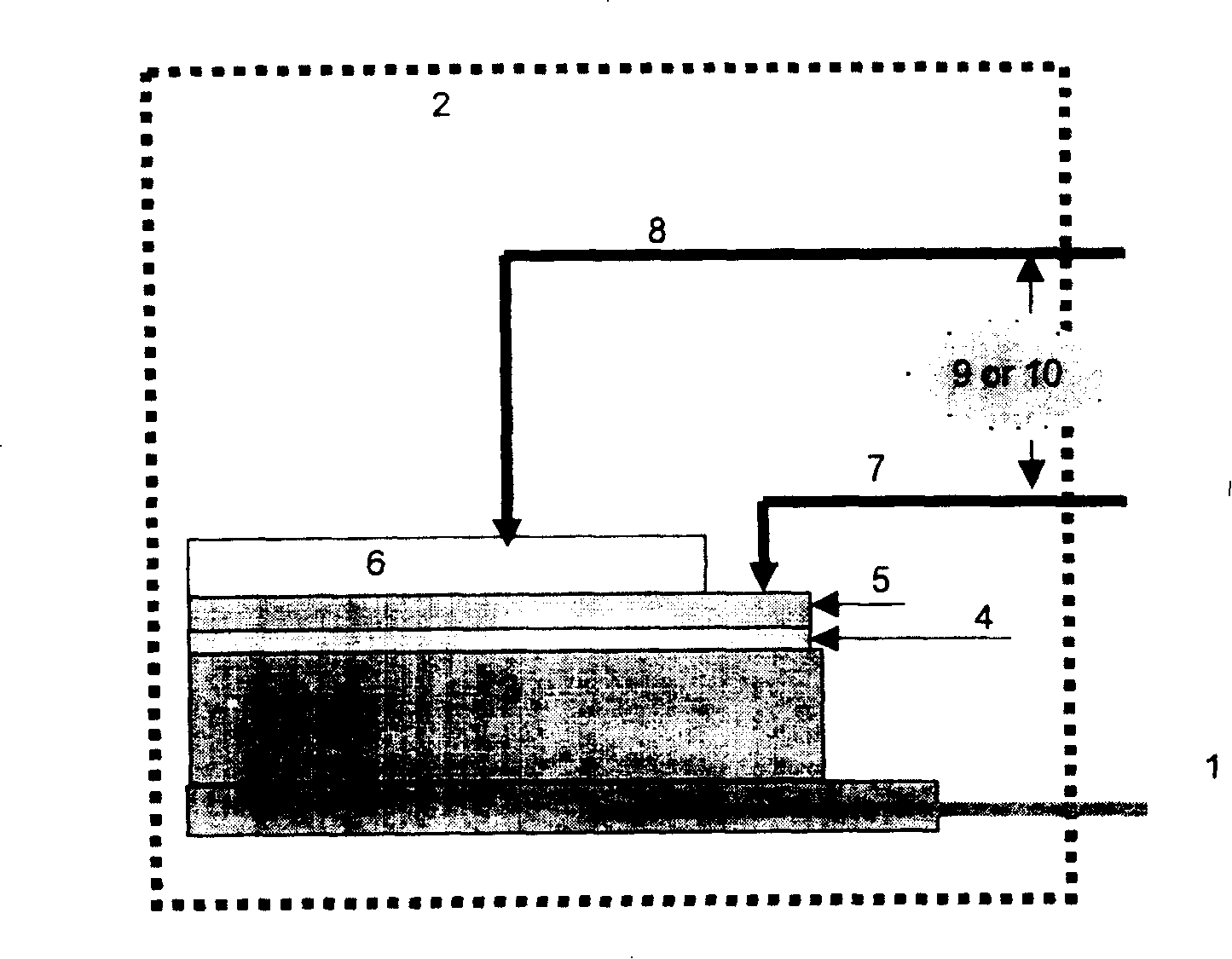

[0034] Embodiment 1: Mainly use magnetron sputtering to deposit materials, and its simple unit device preparation steps and testing methods are:

[0035] (1) Use a silicon oxide wafer as the substrate, the thickness of silicon oxide is 1 μm, first use the magnetron sputtering method to deposit the transition layer Ti at room temperature, the thickness is about 20nm, and then sputter the lower electrode material W, the thickness is 100nm left and right, the power is 300W, and the background vacuum is 4×10 -6 torr, sputtering vacuum is 0.10Pa.

[0036] (2) Magnetron sputtering of GeTeSb film with a thickness of 80 nm, a sputtering power of 100 W, and a background vacuum of 3 × 10 -6 torr, the sputtering vacuum is 0.08Pa.

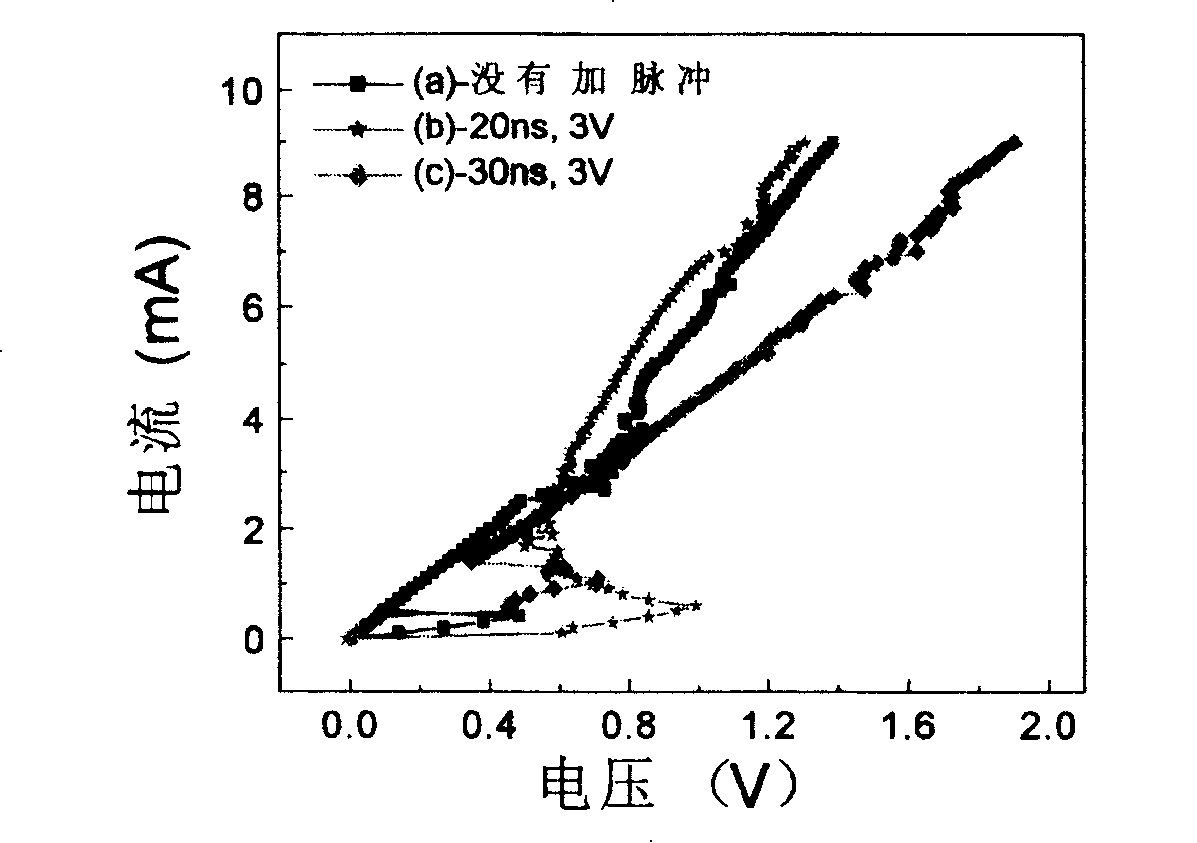

[0037] (3) Put the prepared materials into figure 1 In the closed container shown, according to Figure 4 The temperature is controlled by rising and falling as shown, and can be evacuated, filled with liquid nitrogen or other gas protection as needed. A ...

Embodiment 2

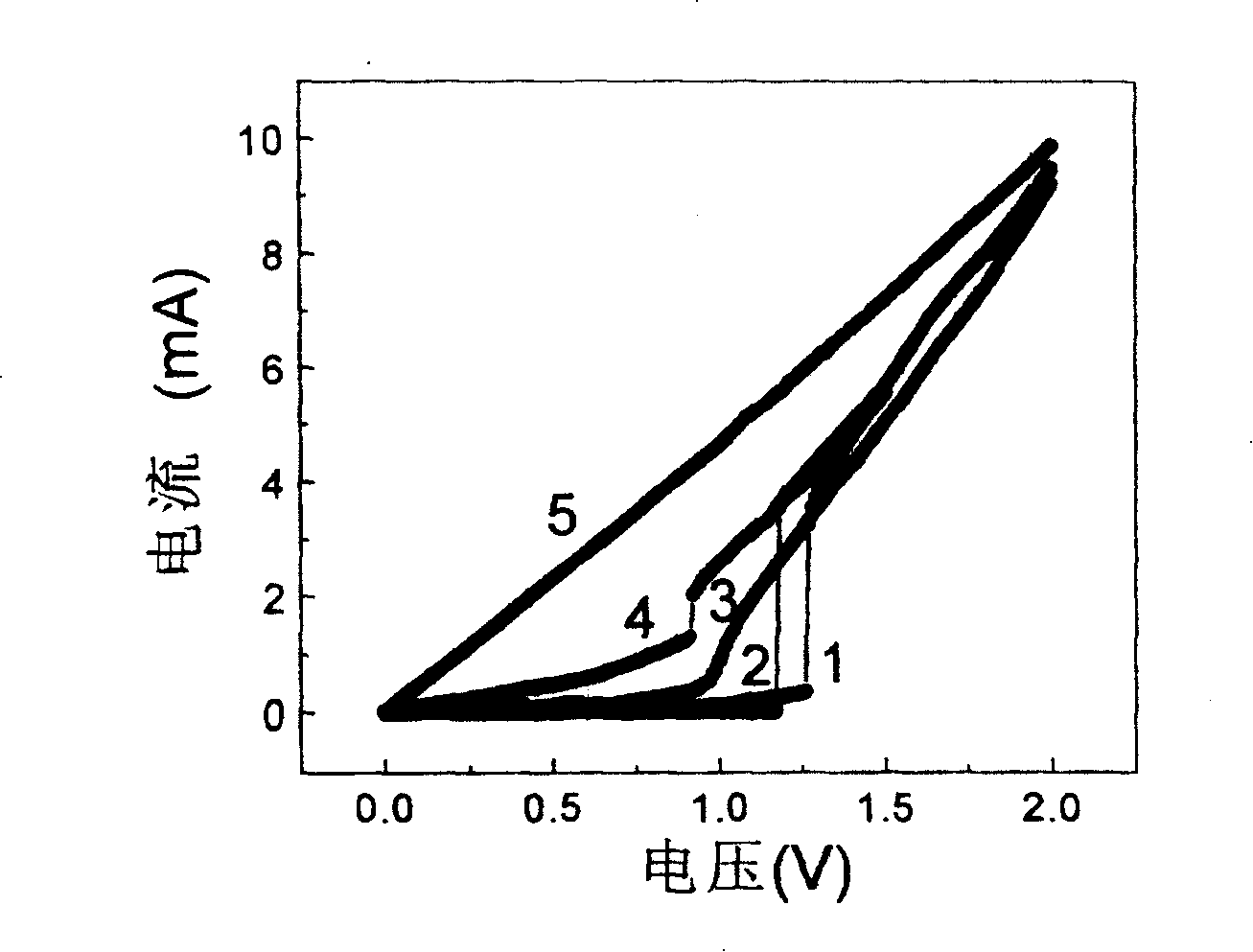

[0039] Example 2: Example 1 (1)-(4) remain unchanged, by rotating and moving the CASCADE RHM-06 probe station. Characterizing the I-V properties of each point of the GeTeSb film on a 4-inch silicon wafer, we can see the uniformity, repeatability and stability of the GeTeSb film.

Embodiment 3

[0040] Example 3: Example 1 (1)-(4) remained unchanged, and the I-V characteristics were studied in a closed heating container at a temperature of 120°C. result with figure 2 resemblance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com