Method for producing metallic lead and zinc by using lead-zinc containing waste slag or lead-zinc monoxide mine

A lead-zinc oxide, metal lead technology, applied in the improvement of process efficiency, photography technology, instruments and other directions, can solve the problems of low product purity, high energy consumption, serious environmental pollution of lead dust, etc. The effect of low consumption and good environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

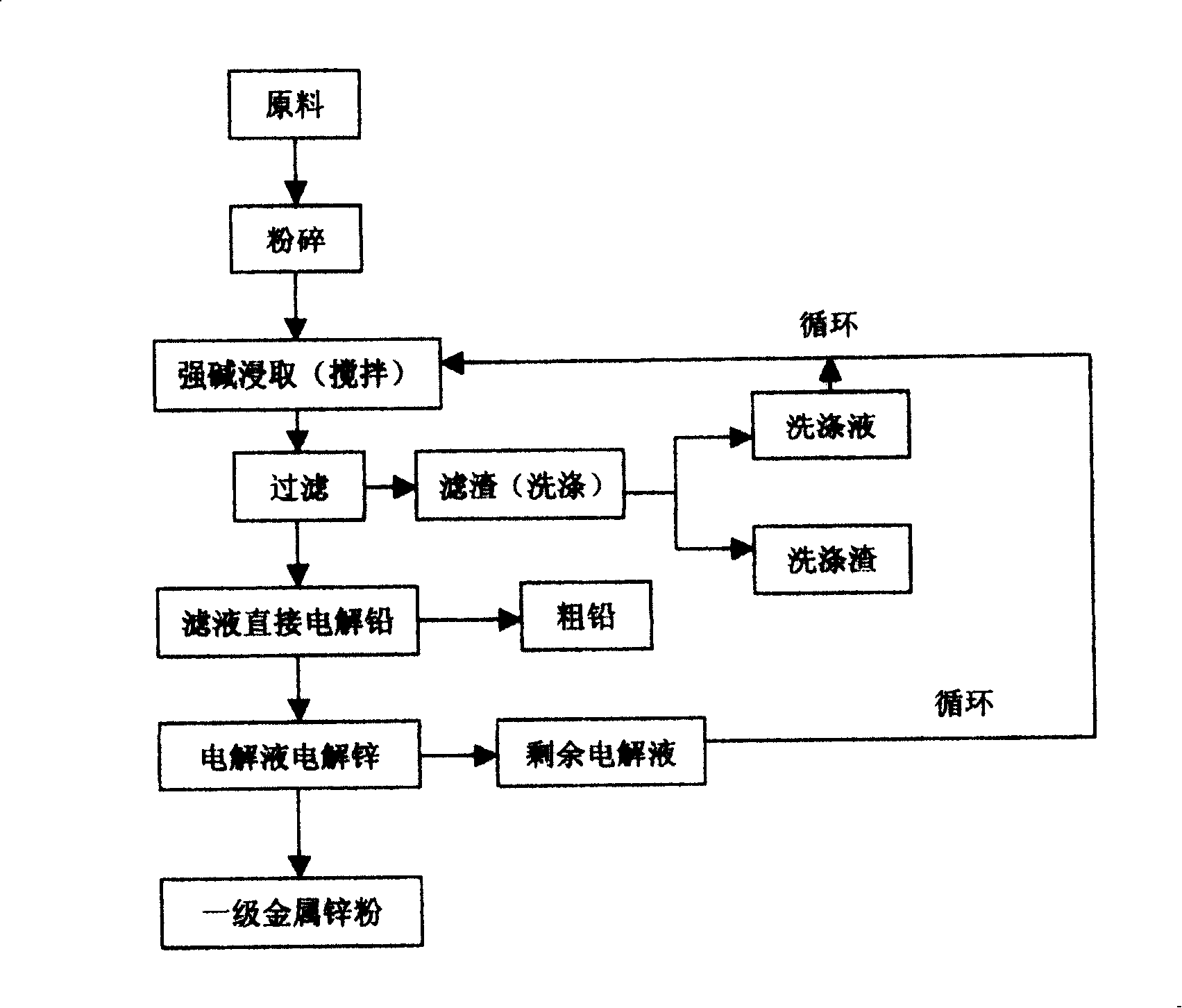

[0013] see figure 1 . Taking lead-zinc ash (lead-zinc waste residue) from a factory as raw material, its composition is shown in Table 1:

[0014] Table 1 The composition of lead and zinc ash in a factory

[0015] Element

[0016] First, immerse 500g of the above-mentioned lead-zinc ash into 5L of 5mol / L NaOH solution, the leaching temperature is 30°C, and stir for 200 minutes at a speed of 500 rpm, and the lead-zinc in the lead-zinc ash enters the solution. Then filter while hot to obtain filter residue and filtrate. The composition of the filtrate is shown in Table 2:

[0017] Table 2 Composition of lead-zinc ash alkali leaching solution

[0018] Element

[0019] After the filter residue is washed with NaOH solution and water, the washing water is returned to be used as a strong alkali leaching cycle, and the washing residue is landfilled. The filtrate is directly used for electrolysis of lead, using stainless steel as cathode and anode, at 20-30℃,...

Embodiment 2

[0021] Taking lead oxide ore as raw material, its composition is shown in Table 3:

[0022] Table 3 Composition of a certain lead-zinc oxide ore

[0023] Element

[0024] 240g of the above-mentioned lead-zinc oxide ore was pulverized to 0.1-1mm, then immersed in 6L 5mol / L NaOH solution, the leaching temperature was 90°C, and stirred for 100 minutes at a speed of 1000 rpm, and the lead and zinc in the ore powder entered the solution. Then filter while hot, and the filtrate composition is shown in Table 4:

[0025] Table 4 composition of lead-zinc oxide ore alkali leaching solution

[0026] Element

[0027] The filter residue was washed with NaOH solution and water and then landfilled. The filtrate is directly used for electrolysis of lead, using stainless steel as cathode and anode, at 30-50℃, the current density is 1000A / m 2 , the voltage is 1.8-2.0V, the electrolysis is carried out for 2h, and the crude lead with the purity of 98.5% is obtained on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com