Composite section bar of fiber, pure titanium and gold foil, method for producing the same and solidifying mould thereof

A technology for composite profiles and curing molds, which is applied in the field of fiber-pure titanium foil composite profiles and its manufacturing process and curing molds, and can solve the problems of easy displacement of directional fiber reinforcements, large weight, and many materials used for layer positioning fibers , to achieve excellent damage tolerance and residual strength, high elastic modulus, and shear resistance physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

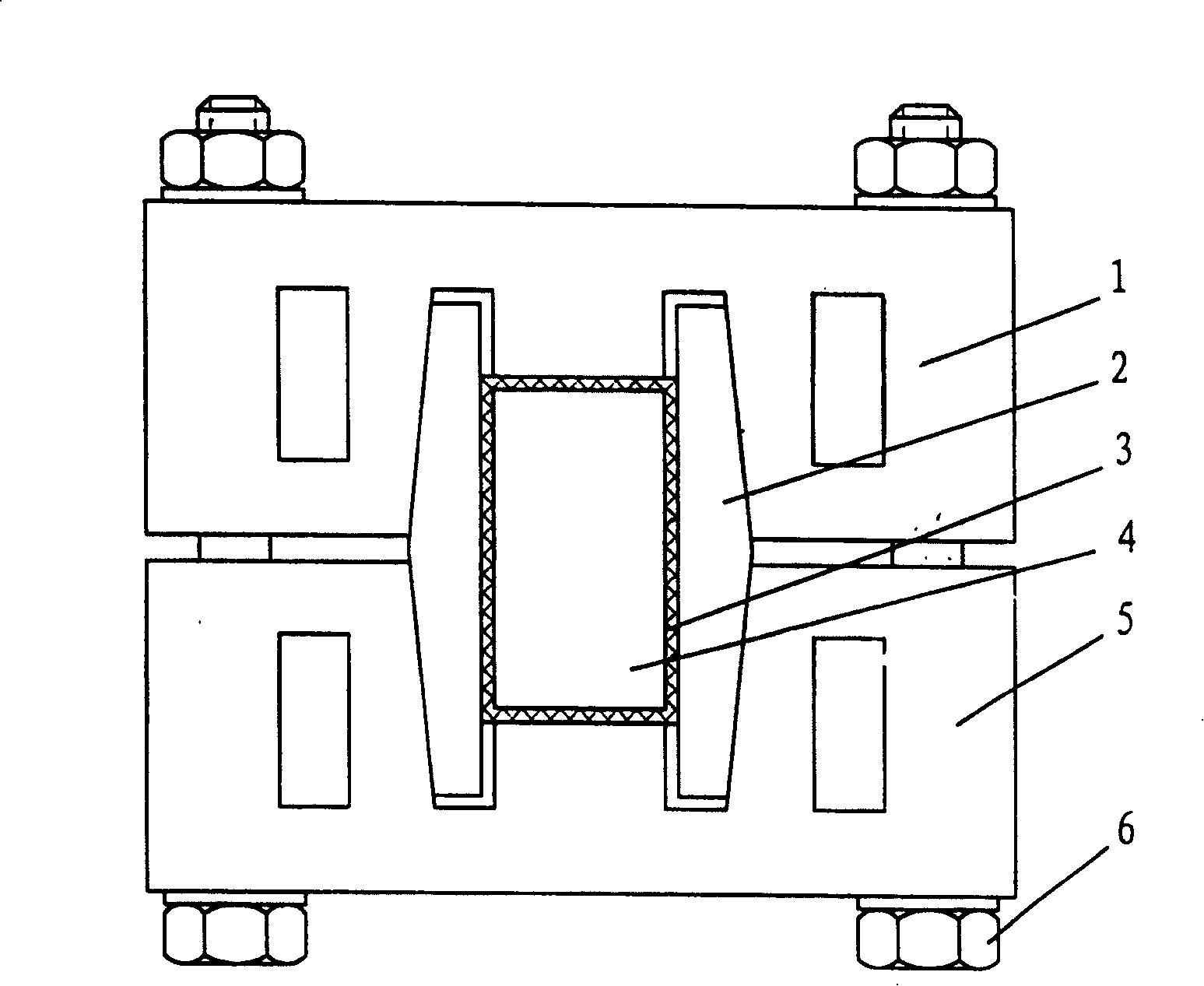

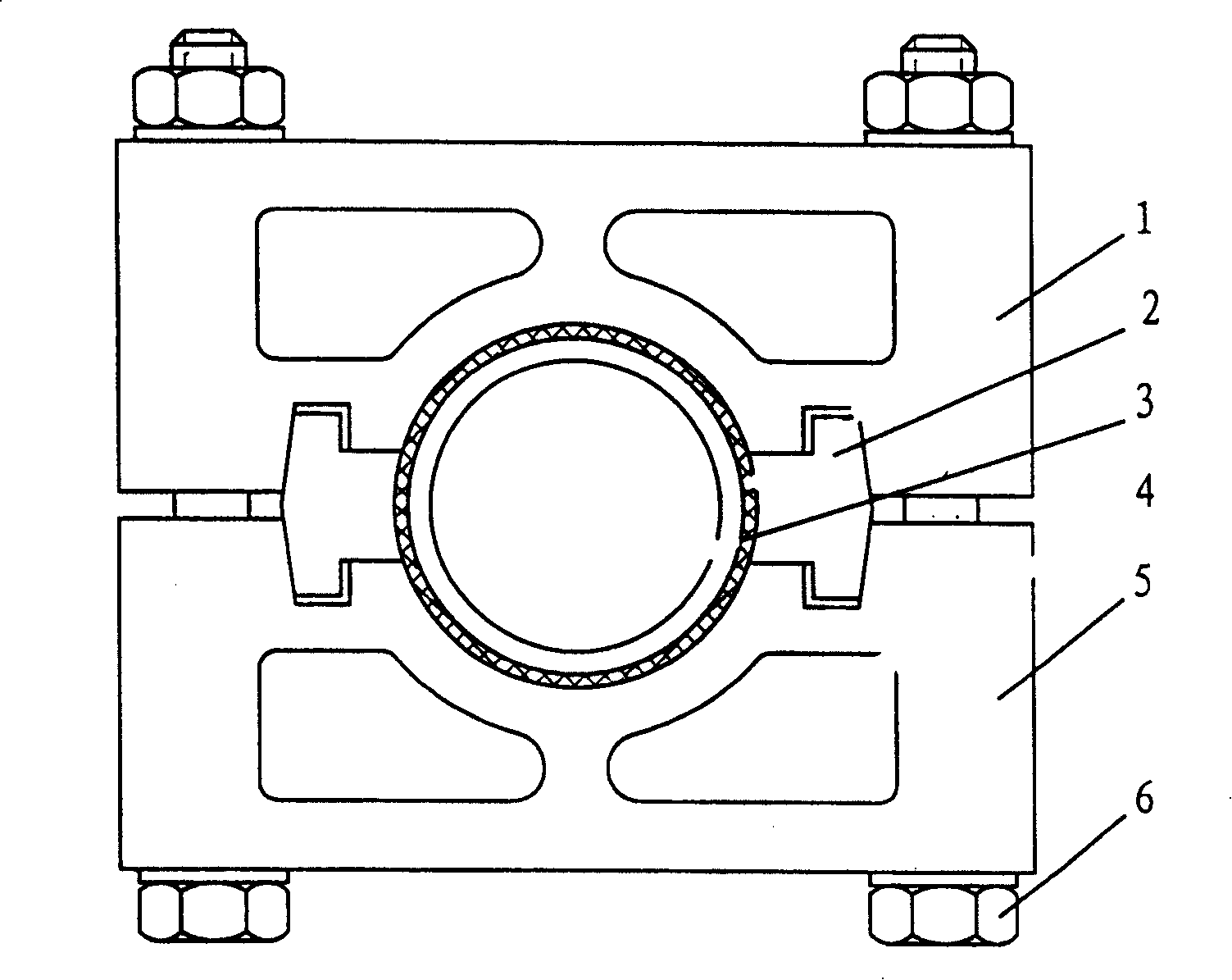

[0049] Use pure titanium foil and carbon fiber cloth, such as one of unidirectional cloth, two-way weave plain weave, twill weave, five satin weave, eight satin weave or two-way 45 three-dimensional weave cloth, each impregnated with epoxy resin glue, made of epoxy resin Resin-based two-layer carbon fiber cloth interlayered with pure titanium foil, pre-impregnated tape, multi-directional molded and sizing process round pipe.

[0050] The carbon fiber cloth impregnated with epoxy resin glue is cut into the length with the perimeter of the two outer surfaces of the male mold, and the pure titanium foil soaked with epoxy resin glue is cut into the length with the perimeter of one outer surface of the male mold; On the male mold pre-coated with release agent, spread the carbon fiber cloth with the perimeter of the two outer surfaces on the male mold, and spread the titanium foil on the other carbon fiber unidirectional cloth that has not been rolled. , put it on the rolling platfo...

Embodiment 2

[0053] Use pure titanium foil and high-strength and high-modulus polyethylene (PE) bulletproof fiber bidirectional woven cloth to impregnate high-strength and high-modulus polyethylene (PE) bulletproof fiber resin glue respectively to make a high-strength and high-modulus polyethylene (PE) bulletproof fiber resin glue as the matrix. Polyethylene (PE) bulletproof fiber two-way woven fabric with pre-impregnated tape interlayer of pure titanium foil multi-directional molded profiles.

[0054] The high-strength high-modulus polyethylene (PE) bulletproof fiber bidirectional woven fabric impregnated with epoxy resin glue is cut into the length of an outer surface circumference of the male mold, and the pure titanium foil impregnated with high-strength high-modulus polyethylene (PE) bulletproof fiber resin glue Cut to the length that has the circumference of the two outer surfaces of the male mold; on the male mold that has been pre-brushed with release agent, first spread the pure ti...

Embodiment 3

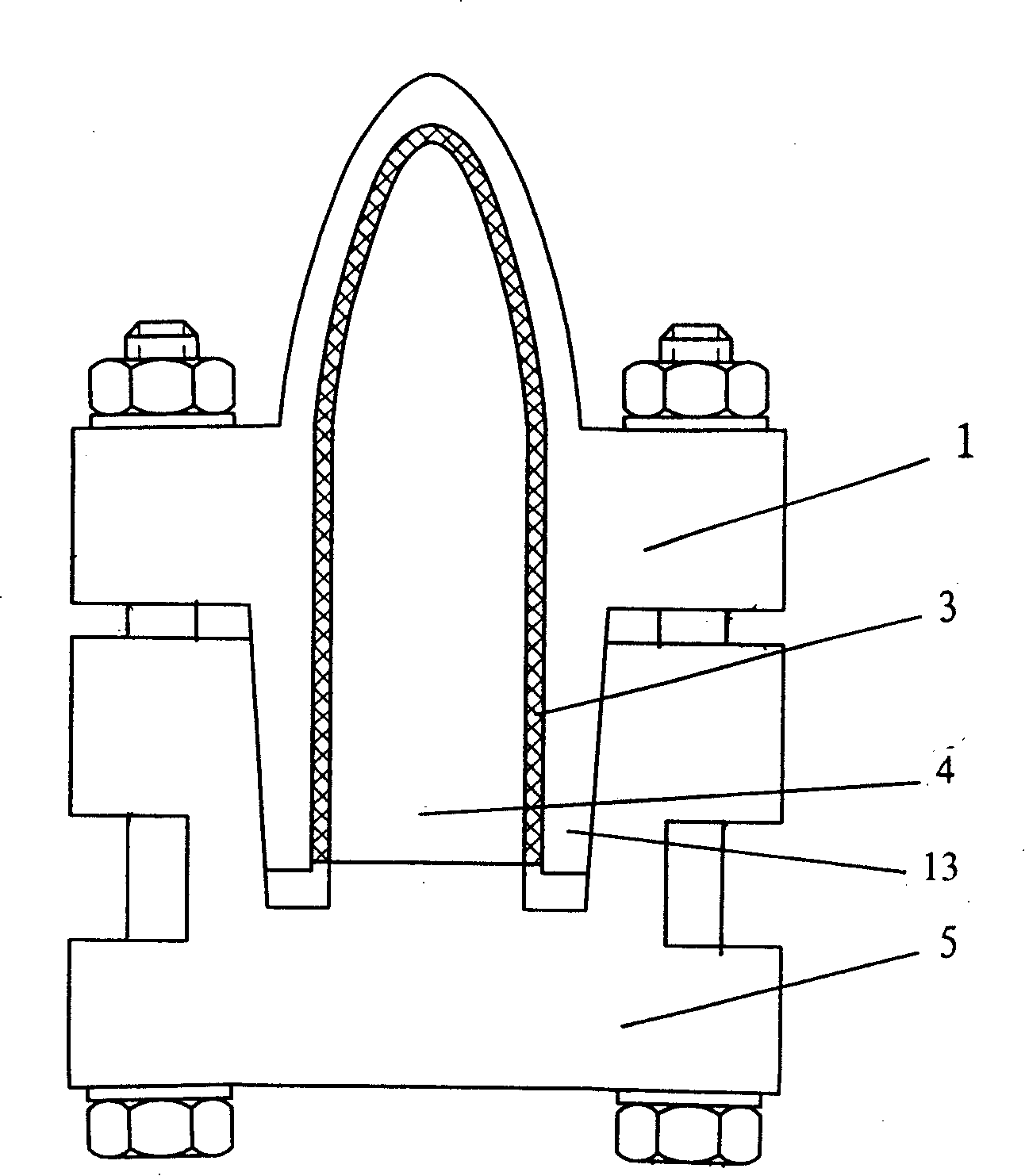

[0057] Using pure titanium foil and aramid fiber two-way braided fabric respectively impregnated with phenolic resin glue to make two-layer aramid fiber two-way braided fabric with phenolic resin as the matrix, multi-directional molding and sizing process of pre-preg adhesive cloth with pure titanium foil interlayer round tube.

[0058] The aramid fiber bidirectional woven cloth impregnated with phenolic resin glue is pre-cut to have the length of the perimeter of the two outer surfaces of the male mold, and the pure titanium foil impregnated with phenolic resin glue is pre-cut to have the perimeter of one outer surface of the male mold length. On the male mold pre-coated with the release agent, spread the aramid bidirectional woven cloth with two layers on the male mold, and spread the titanium foil on the other unrolled aramid bidirectional On the woven cloth, put it on the rolling platform machine and roll and roll it to make an uncured profile of aramid two-way braided pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com