Microwave disinfecting drying machine

A technology for microwave sterilization and dryers, which is applied to dryers, drying, and household clothes dryers. Work efficiency, less auxiliary equipment, and low investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

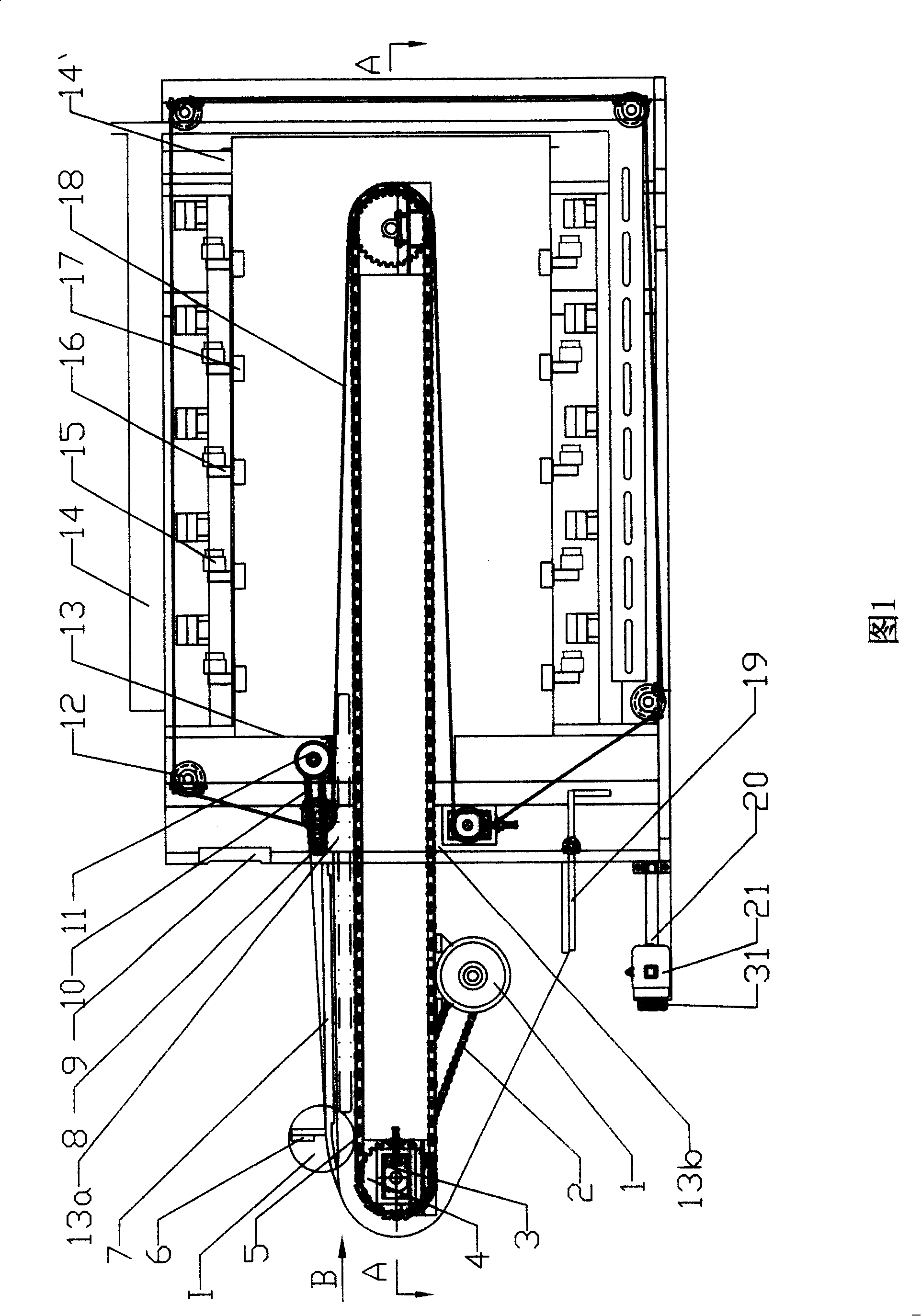

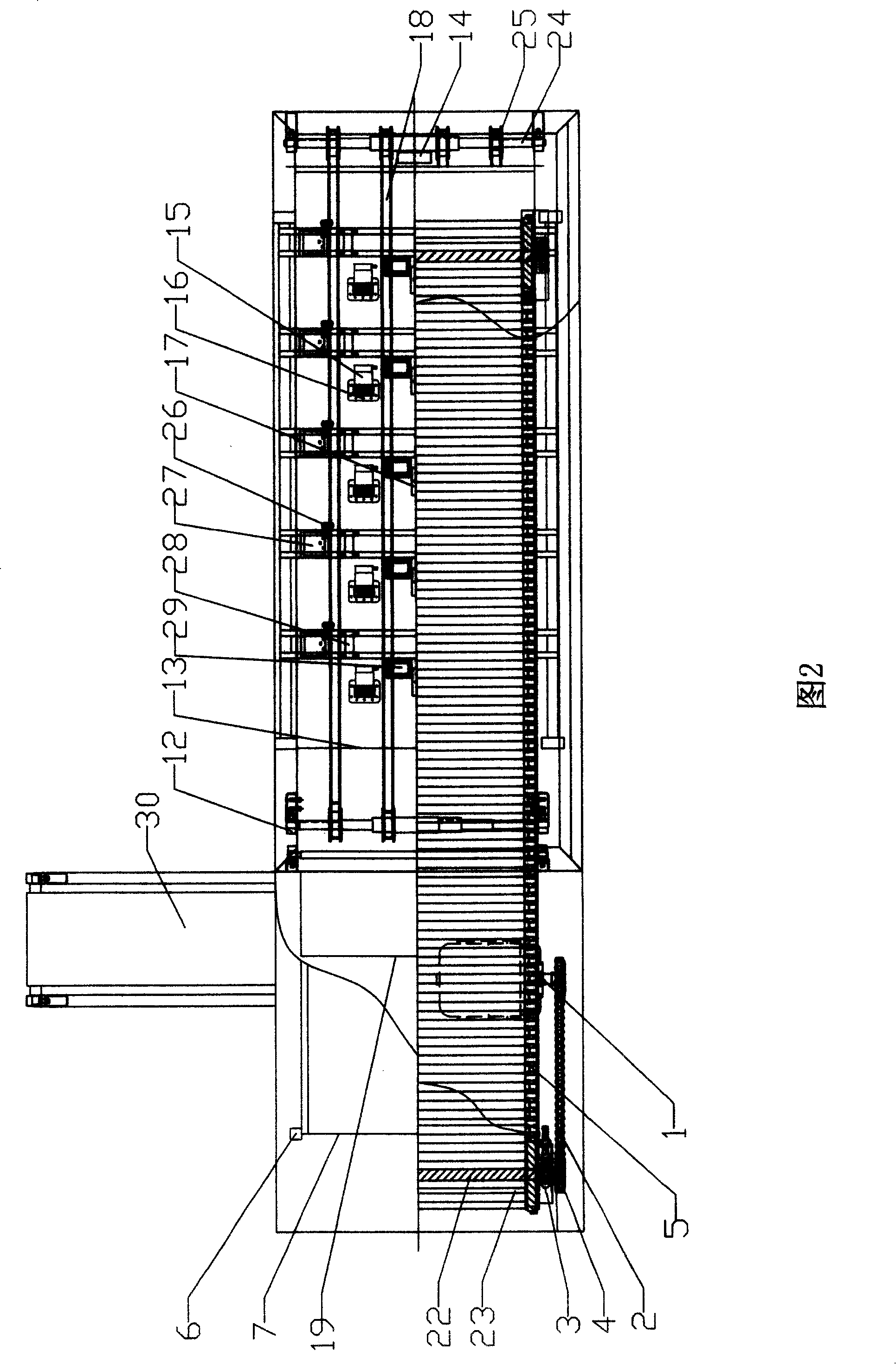

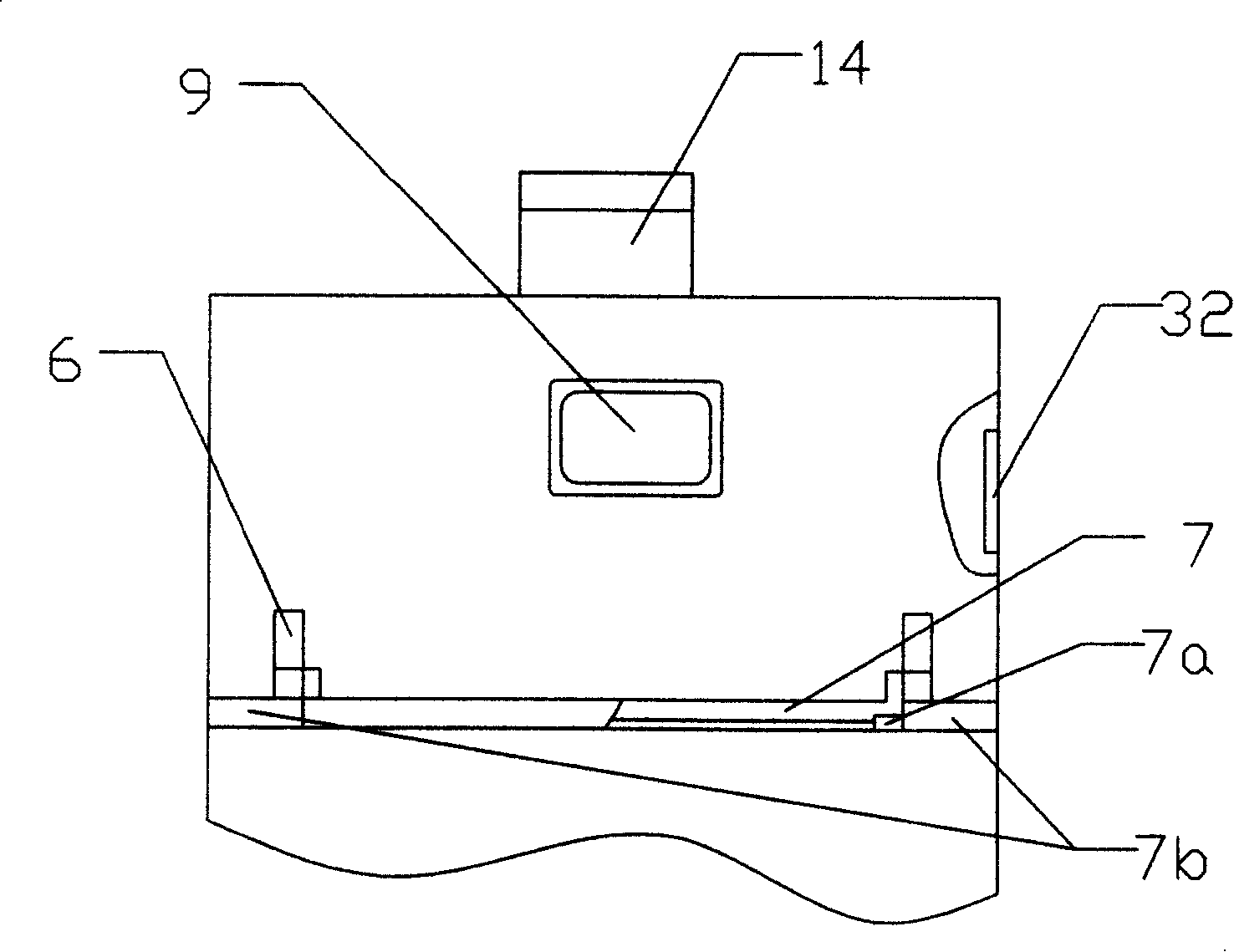

[0015] The structure of the microwave sterilization dryer of this embodiment can be seen from Figure 1, Figure 2 and Figure 4 It can be seen that it contains a casing (shown by a thin line on the periphery in Figure 1 and Figure 2), with a magnetron 15, a wave guide 16, a centrifugal fan 29, a transformer 27, and an axial flow inside the casing. The fan 28, the capacitor 26, the microwave heating chamber 13, the dehumidifier 14, the chain plate transmission mechanism and the pressure belt transmission mechanism that synchronously entrain the movement of the bedding, the microwave leakage prevention door 7 and the door movement mechanism at the inlet end 13a of the cabinet, and the on-board mechanism The gravity door 19 and the bedding transfer mechanism, the light curtain 6, the control panel 32 and the display 9 at the exit end 13b of the shell.

[0016] In the upper and lower parts of the microwave heating cavity 13, 10 magnetrons 15 capable of generating microwaves, 10 waveguid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com