Flue gas wet desulfurizing process

A wet desulfurization and flue gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of low desulfurization efficiency, high cost, easy blockage of equipment, etc., and achieve enhanced contact effect and enhanced stability. The effect of good permeability and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

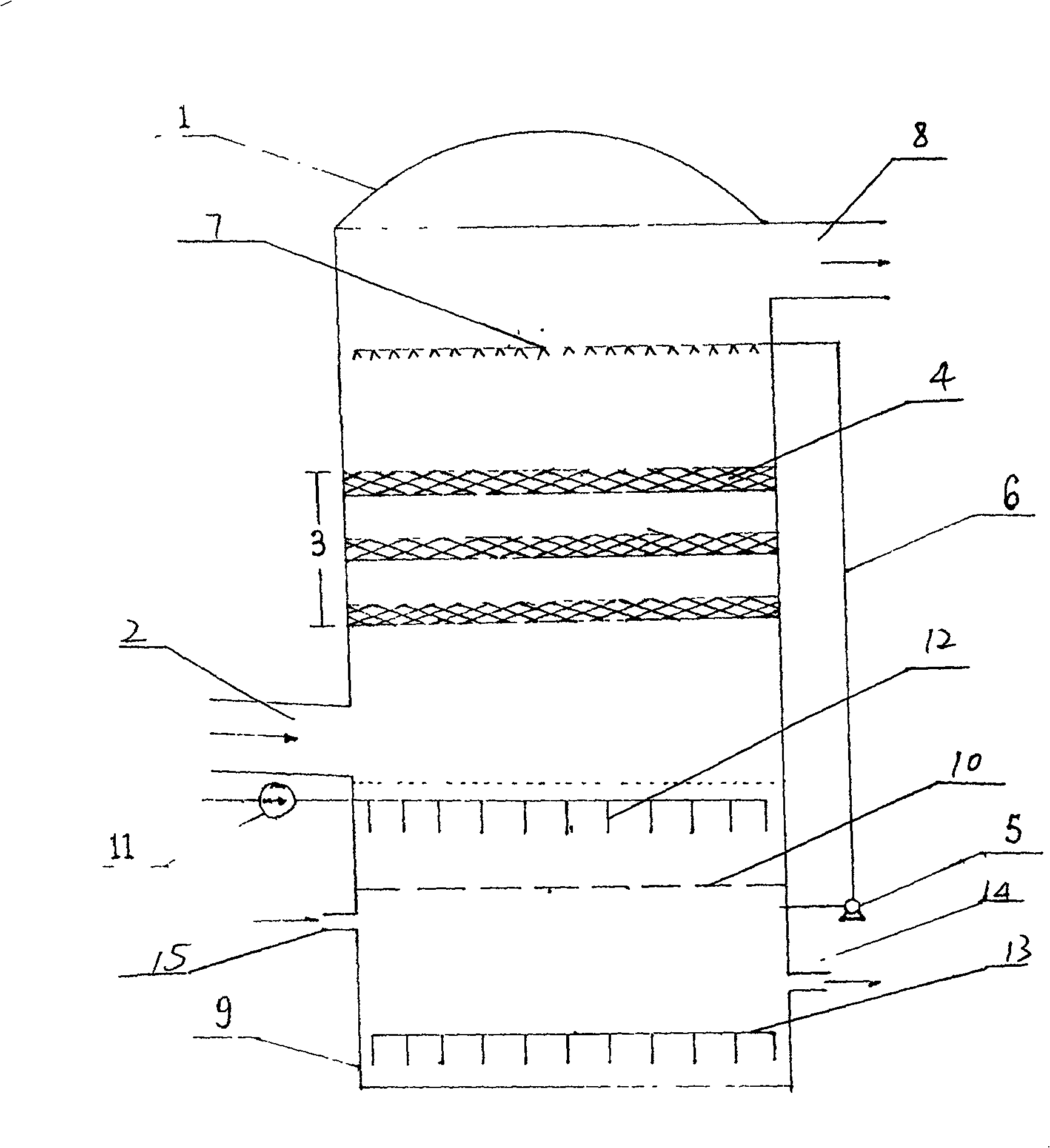

[0019] As shown in the figure, the flue gas from boilers, kilns, metallurgical furnaces and other devices enters the desulfurization tower 1 from the inlet 2 and rises, and is basically uniformly distributed in the multi-layer wire mesh area 3; the hydration absorption of gypsum and slaked lime The mixed liquid of the agent is transported by the slurry pump 5 and the infusion pipe 6 to the spray device 7 on the upper part of the desulfurization tower and sprayed down evenly; the flue gas is in reverse contact with the hydration absorbent, mainly forming a closer contact in the multi-layer wire mesh area , so that SO in the flue gas 2 After a chemical reaction occurs, it is transferred to the liquid phase, and the clean flue gas is discharged from the outlet 8 on the upper part of the desulfurization tower.

[0020] Absorbed SO 2 The hydration absorbent falls into the circulation tank 9 at the bottom of the desulfurization tower; the circulation tank is divided into two layers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com