Acuminium-base laminated high-over load piezoelectric driver

A piezoelectric driver, high overload technology, applied in the field of piezoelectric ceramics, can solve the problems of inability to apply high overload environment, shear resistance, tensile resistance and overload resistance, and achieve high tensile resistance, output voltage and capacitance Low load capacity, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

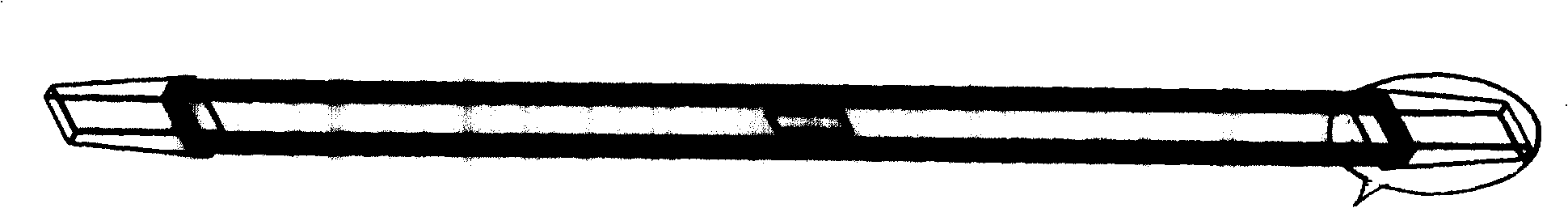

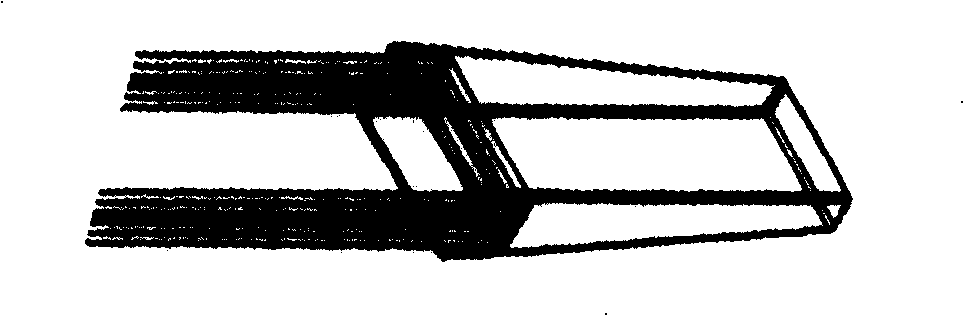

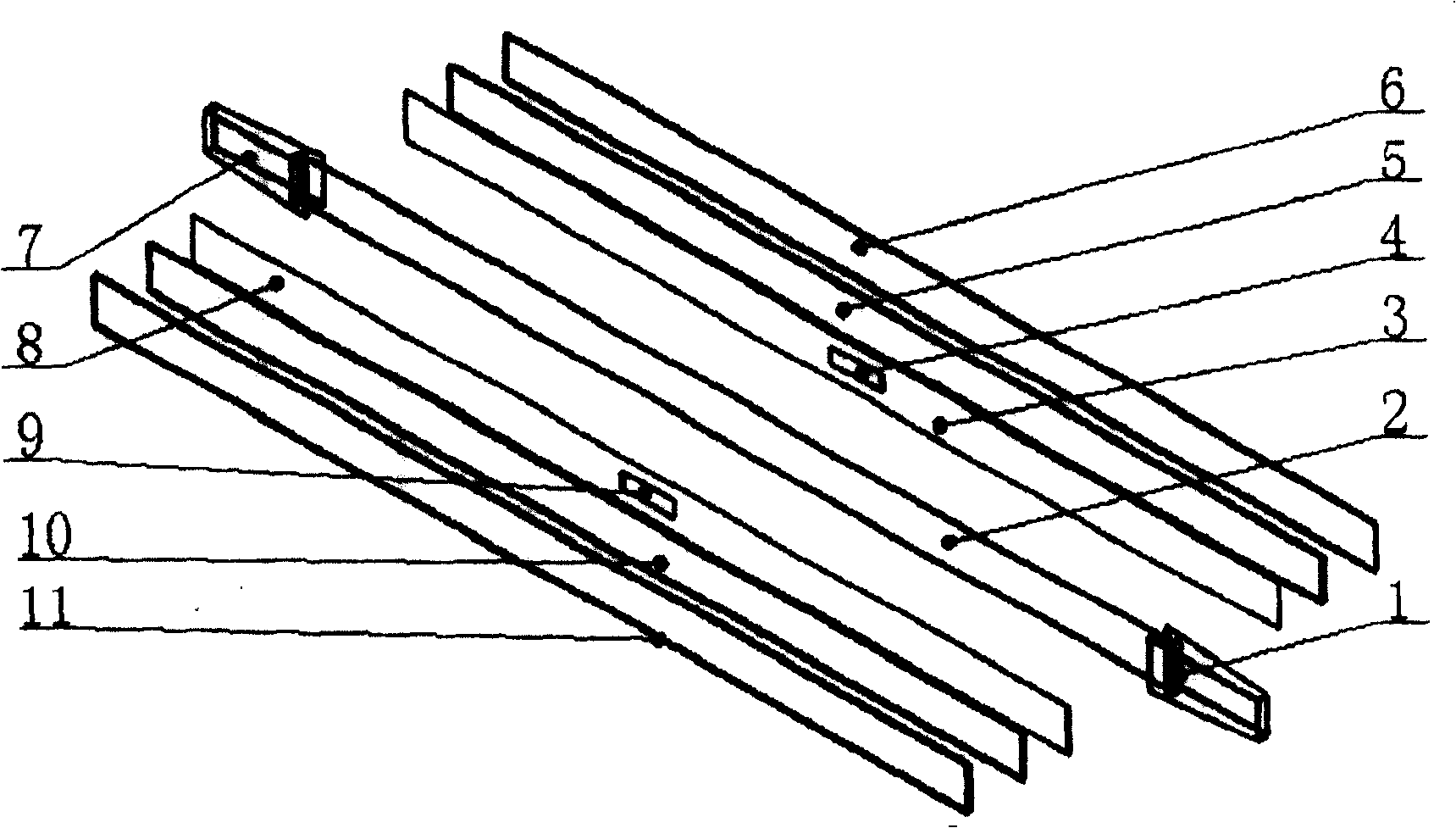

[0010] The aluminum-based laminated high-overload piezoelectric driver includes two piezoelectric ceramic laminates that are mechanically connected in series and electrically connected in parallel. An aluminum foil substrate 2 is bonded between the two piezoelectric ceramic laminates, and the aluminum foil substrate 2 is bonded to the piezoelectric ceramic laminate. The contact surface (at the same time as the existing bonding) is locally bonded with conductive epoxy, and the outer surfaces of the two piezoelectric ceramic laminates (backwards to the aluminum foil substrate are the outer) are connected as one pole of the electrode, and the aluminum foil substrate 2 is the pole of the electrode. the other pole. The two ends of the driver are snapped into and bonded in the glass fiber masses 1 and 7 through epoxy resin. The glass fiber masses 1 play the role of further clamping the piezoelectric ceramic laminate and the aluminum foil substrate on the one hand, and protect the Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com