Herbicide intermediate 3-chloro-2-methyl aniline production process

A technology of methylaniline and production process, which is applied in the field of preparation of pesticide intermediates, can solve the problems of three wastes, harsh conditions, and low yield, and achieve the effects of simple feeding and post-treatment, safe and mild reaction conditions, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

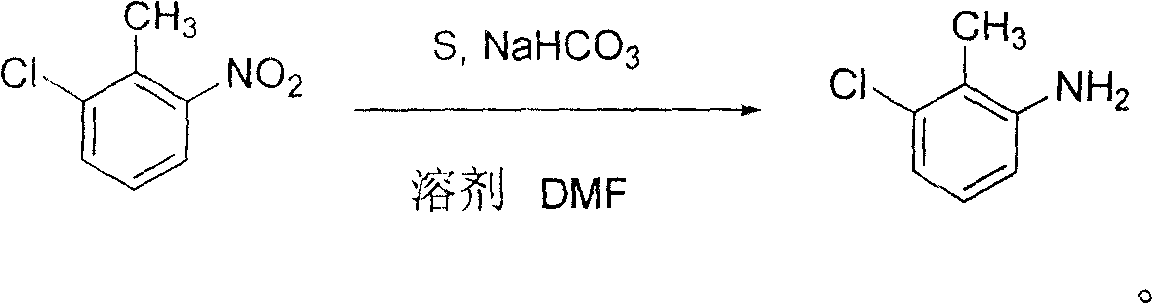

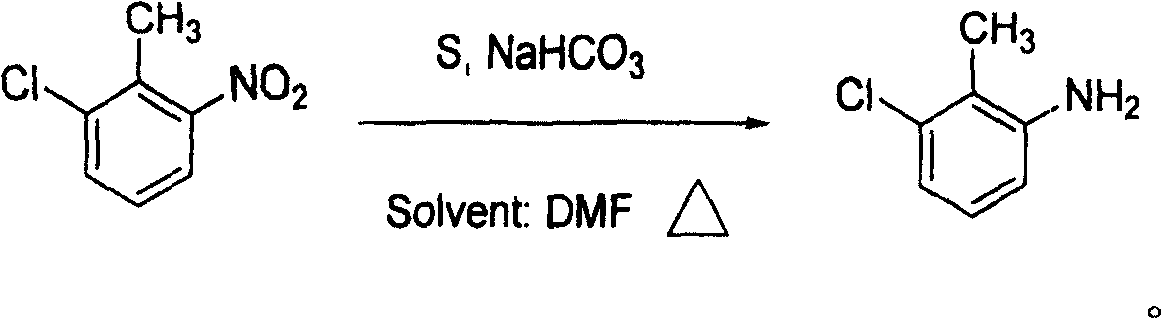

Method used

Image

Examples

Embodiment 1

[0019] In the 1000 milliliter three-necked flask, add 500 milliliters of N,N-dimethylacetamide solvent successively, 51 grams (0.3 moles) 2-chloro-6-nitrotoluene, 29 grams (0.9 moles, 3 equivalents) sulfur, 76 grams of sodium bicarbonate (0.9 moles, 3 equivalents), stirred and reacted at 130°C for 20 hours, terminated the reaction, then filtered, and the filtrate was fractionated under reduced pressure to obtain light yellow liquid 3-chloro-2-methylaniline, boiling point: 115~117 °C (10mmHg), yield 80%, purity 99% (GC).

Embodiment 2

[0021] In the 1000 milliliter three-necked flask, add 500 milliliters of N,N-dimethylacetamide solvent successively, 51 grams (0.3 moles) 2-chloro-6-nitrotoluene, 48 grams (1.5 moles, 5 equivalents) sulfur, 126 grams of sodium bicarbonate (1.5 moles, 5 equivalents), stirred and reacted at 110°C for 10 hours, ended the reaction, then filtered, and the filtrate was fractionated under reduced pressure to obtain light yellow liquid 3-chloro-2-methylaniline, boiling point: 115~117 °C (10mmHg), yield 77%, purity 99% (GC).

Embodiment 3

[0023] In the 1000 milliliter three-necked flask, add 500 milliliters of N,N-dimethylacetamide solvent successively, 51 grams (0.3 moles) 2-chloro-6-nitrotoluene, 29 grams (0.9 moles, 3 equivalents) sulfur, 76 grams of sodium bicarbonate (0.9 moles, 3 equivalents), stirred and reacted at 140°C for 24 hours, terminated the reaction, then filtered, and the filtrate was fractionated under reduced pressure to obtain light yellow liquid 3-chloro-2-methylaniline, boiling point: 115~117 °C (10mmHg), yield 85%, purity 99% (GC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com