Ablate spherical well cover with multi-layer casting

A multi-layer shell and oblate spherical technology, which is applied in the fields of anti-explosion manhole cover and anti-ballistic, can solve the problem that the manhole cover is not high in anti-explosion load and anti-shock wave strike ability, the manhole cover cannot resist the direct hit of kinetic energy bullets, and the force and stability of the manhole cover In order to improve the anti-explosion shock wave load capacity, save materials and improve the overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

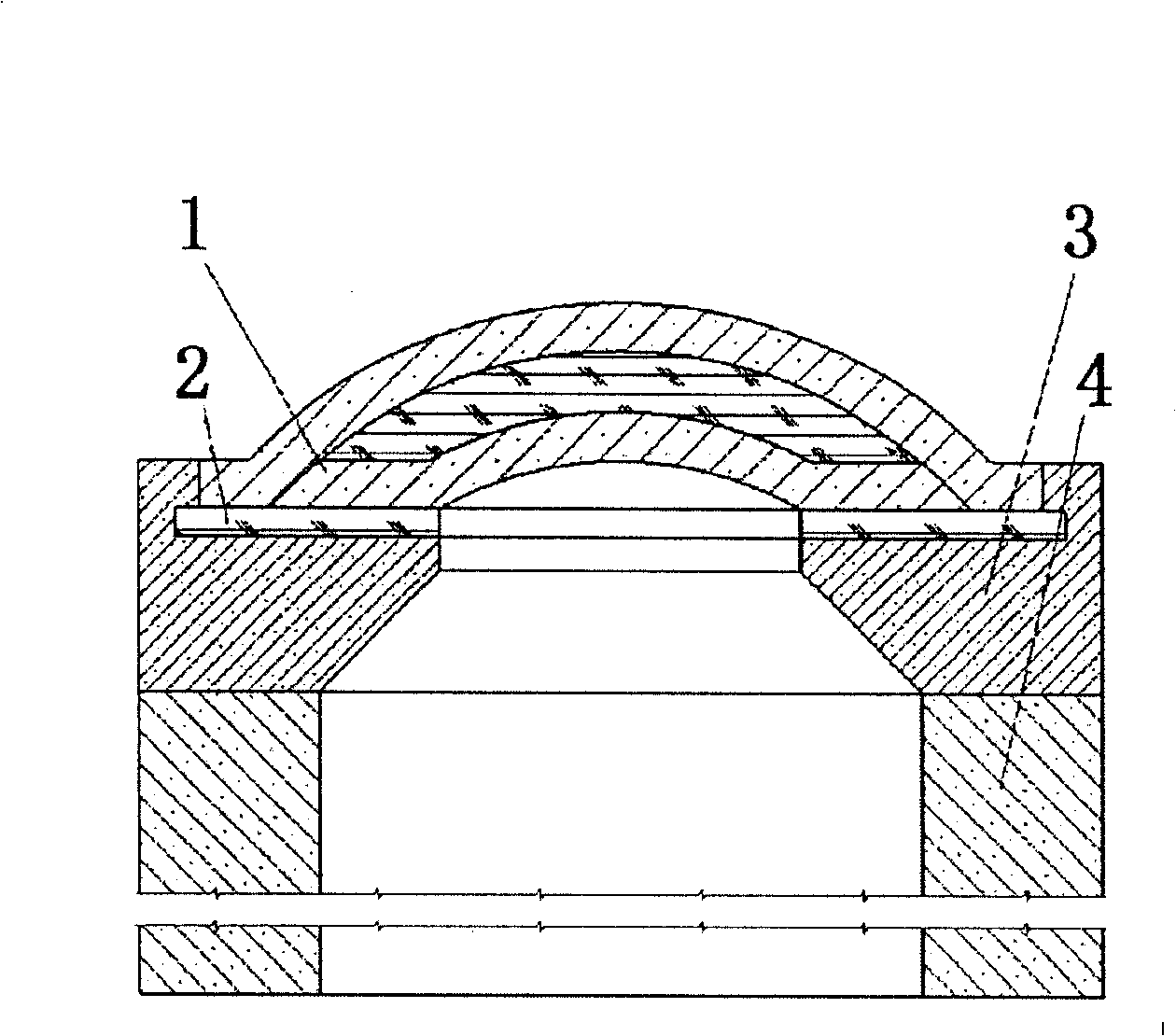

[0020] For an embodiment of the invention see figure 1 , this kind of oblate spherical well cover with multi-layer shell, the well cover 1 is supported on the well frame 3, and the well frame is located on the well shaft 4. There is an elastic buffer pad 2 between the above-mentioned well cover and the well frame. The above-mentioned elastic buffer pad can be a large deformable high-strength rubber pad, the well frame is an assembled hollow cylindrical well frame, the wall thickness of the well frame column gradually decreases from top to bottom, and the shaft is an assembled hollow cylinder with equal wall thickness. The well frame above is a ladle high-strength concrete structure. The assembled steel structure of the well frame 3 and the well shaft 4 is first installed as a whole by welding the connecting plate and bolts, and built in the rock mass with steel bars, and then the well frame and the well shaft assembled steel structure are concreted, and the elastic buffer pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com