Aluminum-titanium-carbon-yttrium intermediate alloy and preparing method thereof

An intermediate alloy and composite structure technology, applied in the field of grain refiner, can solve the problems of C element addition and alloying, difficult to accurately control component content, long reaction time and other problems, achieve broad market application prospects, and low production cost , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

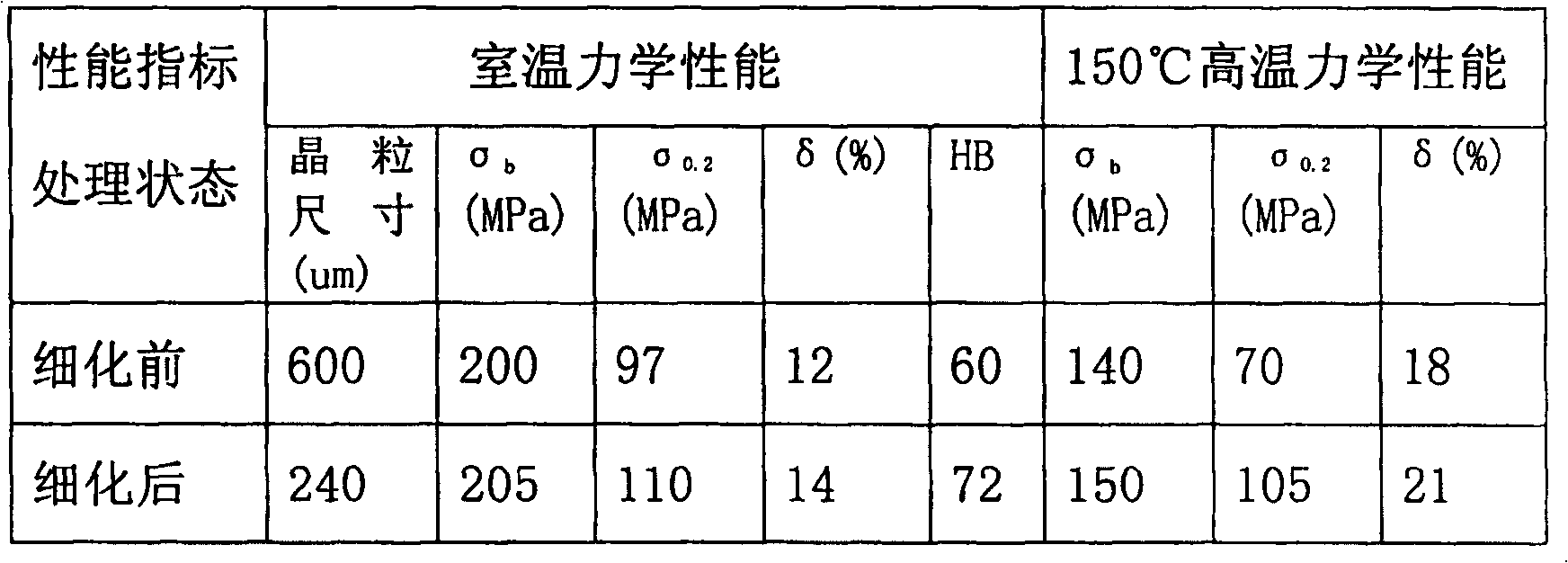

Embodiment approach 1

[0012] First 1. graphite powder, titanium powder and yttrium powder are counted as by mass percent Wt%: Ti 0.50, C1.00, the proportioning requirement of Y 0.10, weigh the raw material and mix and press into prefabricated block for subsequent use;

[0013] II. Preheat the pure aluminum ingot, then put it into a graphite crucible heated to 450°C, and then adjust the temperature to 760°C;

[0014] III. When all the pure aluminum ingots to be loaded are melted, heat up to 830°C, then add spare prefabricated blocks in batches and cover them with cryolite covering agent, keep warm for 25 minutes, remove slag, and then add refining agent C 2 Cl 6 Refining, the amount of refining agent is 1.3% of the total weight of the alloy, while refining, evenly stirring, and then standing for 40 minutes to obtain a clean aluminum, titanium, carbon, yttrium intermediate alloy metal liquid, and then pour it into the preheated Solidification and crystallization in ordinary metal casting molds; then...

Embodiment approach 2

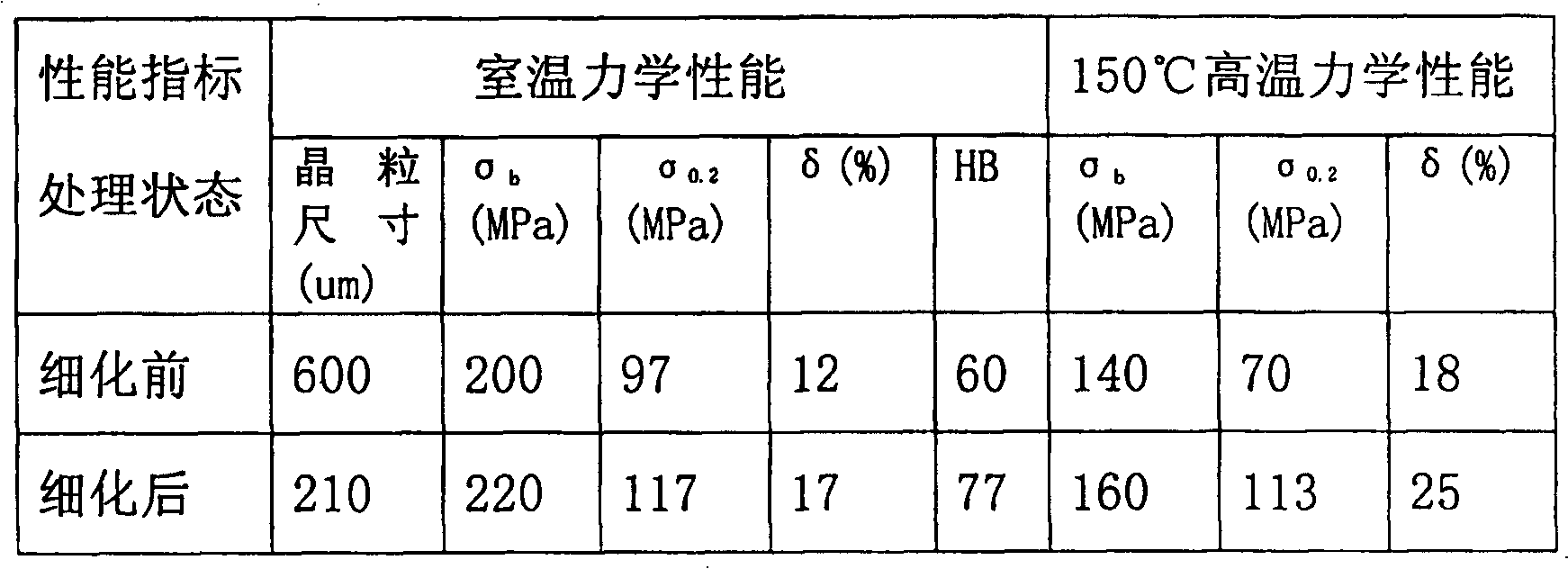

[0018] First 1. graphite powder, titanium powder and yttrium powder are counted as by mass percent Wt%: Ti 6.00, C10.00, the proportioning requirement of Y3.00, it is said that raw material is mixed and pressed into prefabricated block for subsequent use;

[0019] II. Preheat the pure aluminum ingot, then put it into a graphite crucible heated to 450°C, and then adjust the temperature to 760°C;

[0020] III. When all the pure aluminum ingots to be loaded are melted, heat up to 830°C, then add spare prefabricated blocks in batches and cover them with cryolite covering agent, keep warm for 25 minutes, remove slag, and then add refining agent C 2 Cl 6 Refining, the amount of refining agent is 1.3% of the total weight of the alloy, while refining, evenly stirring, and then standing for 40 minutes to obtain a clean aluminum, titanium, carbon, yttrium intermediate alloy metal liquid, and then pour it into the preheated Solidification and crystallization in ordinary metal casting mo...

Embodiment approach 3

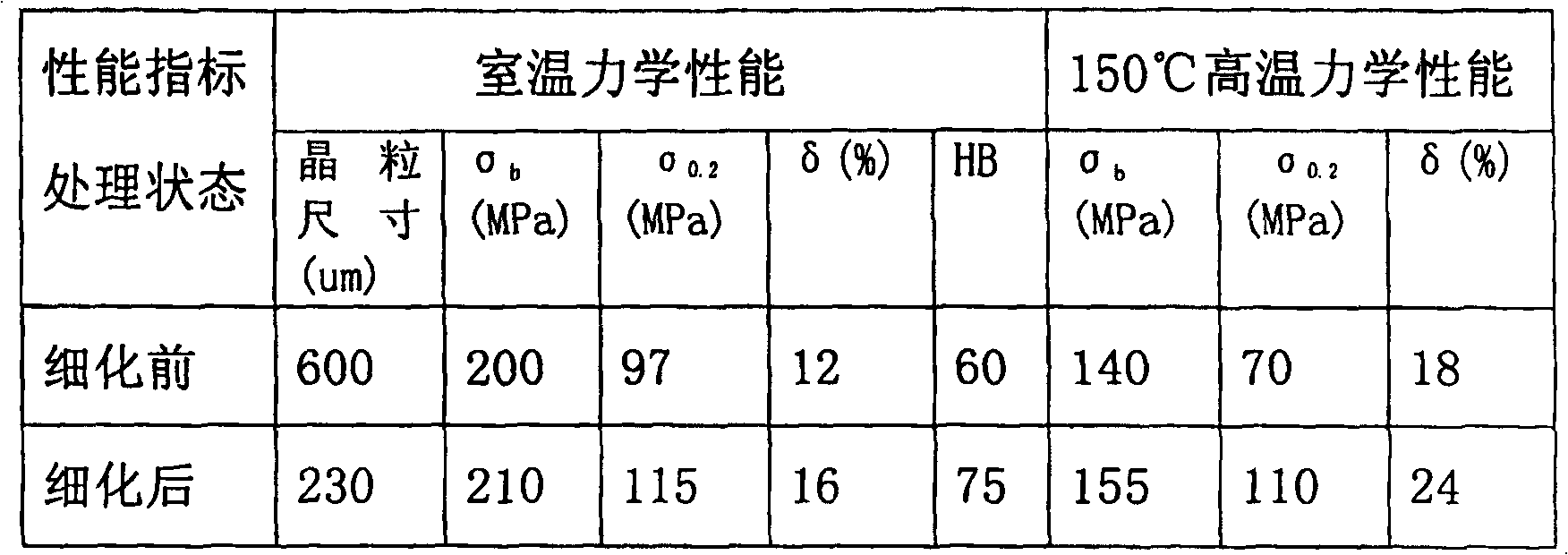

[0024] First 1. graphite powder, titanium powder and yttrium powder are counted by mass percentage Wt%: Ti 3.00, C5.00, the proportioning requirement of Y 2.00, weigh the raw material and mix and press into prefabricated block for subsequent use;

[0025] II. Preheat the pure aluminum ingot, then put it into a graphite crucible heated to 450°C, and then adjust the temperature to 760°C;

[0026] III. When all the pure aluminum ingots to be loaded are melted, heat up to 830°C, then add spare prefabricated blocks in batches and cover them with cryolite covering agent, keep warm for 25 minutes, remove slag, and then add refining agent C 2 Cl 6 Refining, the amount of refining agent is 1.3% of the total weight of the alloy, while refining, evenly stirring, and then standing for 40 minutes to obtain a clean aluminum, titanium, carbon, yttrium intermediate alloy metal liquid, and then pour it into the preheated Solidification and crystallization in ordinary metal casting molds; then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com