Environment friendly dedusting griddle employed wind and water

An environment-friendly, mine-screening technology, applied in screen, solid separation, grille, etc., can solve problems such as increased construction cost, decreased construction quality, environmental pollution, etc., to prevent the loss of wind energy, high product quality, and low dust content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in more detail below in conjunction with accompanying drawing example:

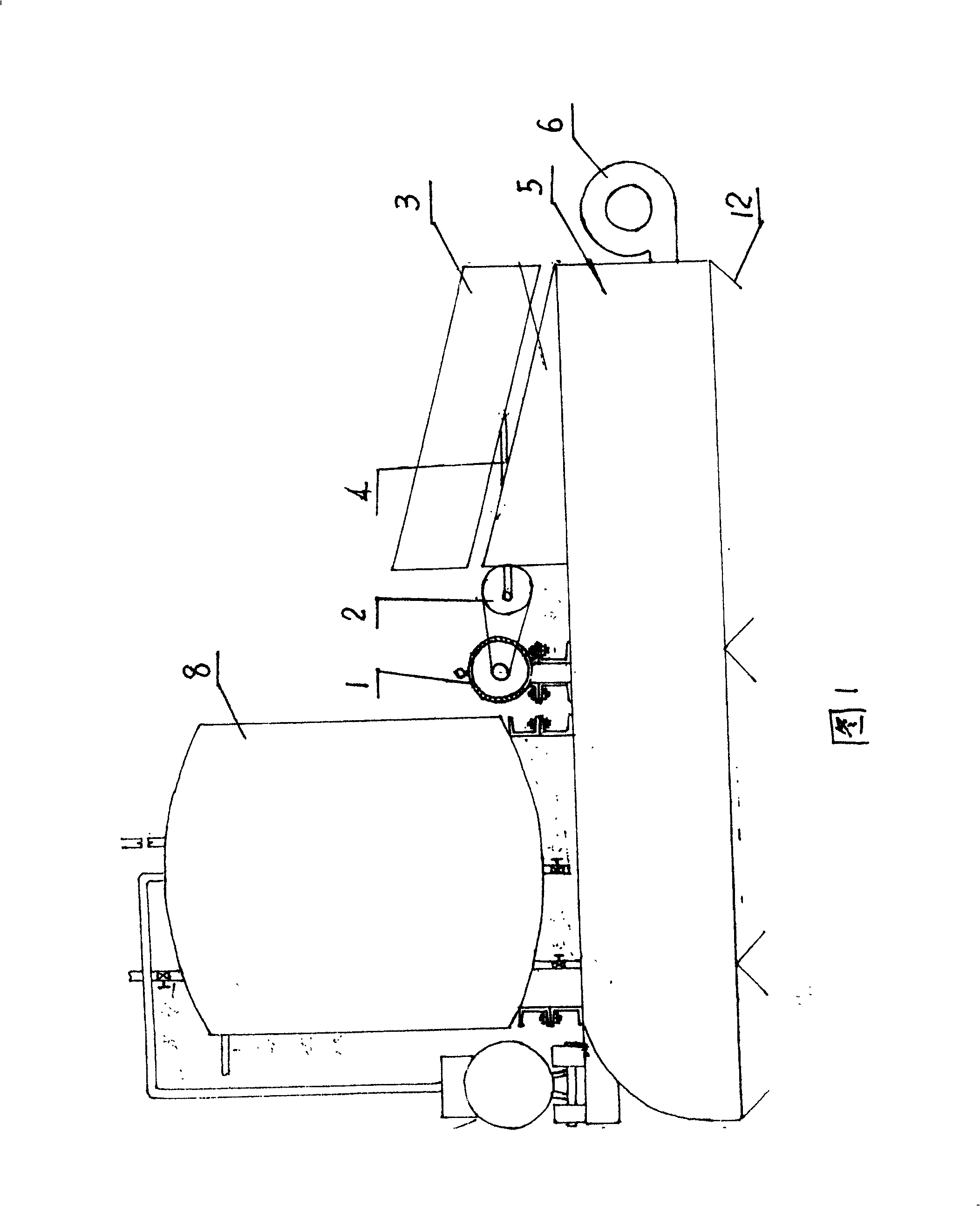

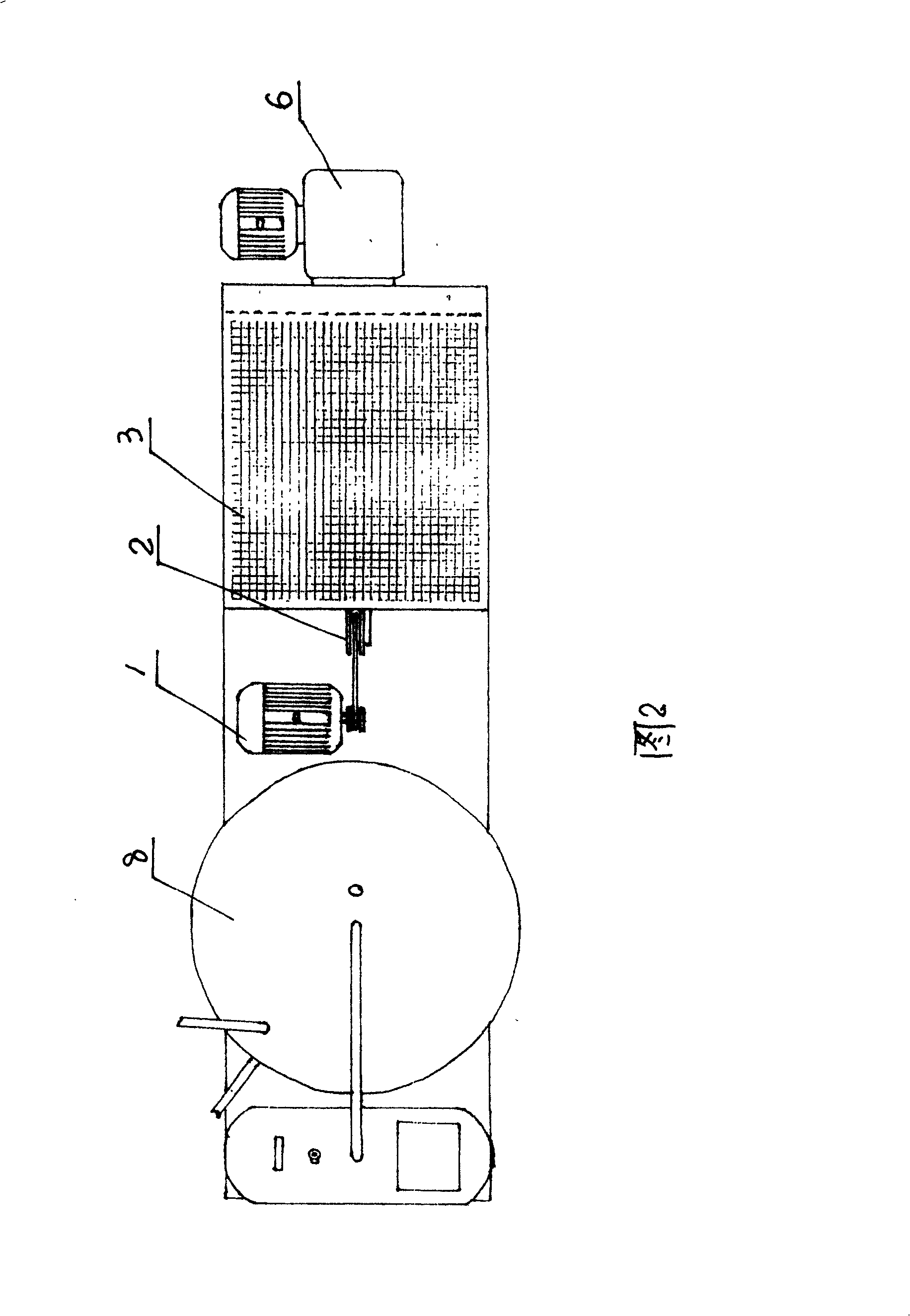

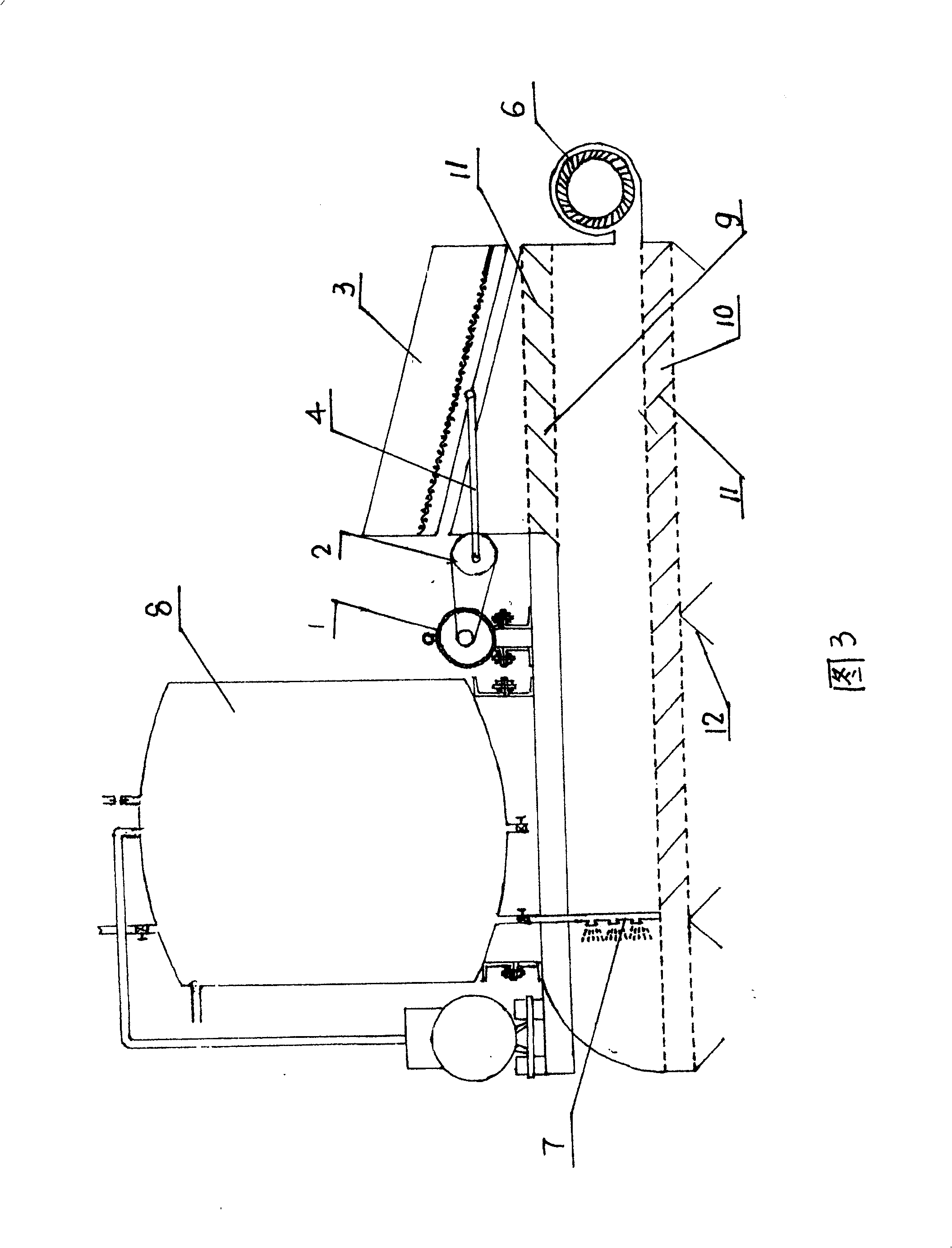

[0015] The composition of Fengshui dust-removing environmental protection mining screen includes a vibrating screen composed of a frame, a motor 1, an eccentric wheel 2, and a wire screen 3. The motor drives the eccentric wheel to rotate, and the eccentric wheel drives the wire sieve to vibrate through the transmission pull rod 4 and the like. A dedusting and sorting drum 5 is arranged at the lower part of the vibrating screen. The front end of the dedusting and sorting cylinder is provided with an air supply device 6, which is a blower or compressed air. The rear end of the dedusting and sorting cylinder is provided with a spraying device 7, and the spraying device is connected with the water supply device 8. The water supply device is one of a high-pressure water pump, a pressure water storage tank or a high-level water tank. The upper part of the dedusting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com