Method and device for preparing 1-aminoanthraquinone

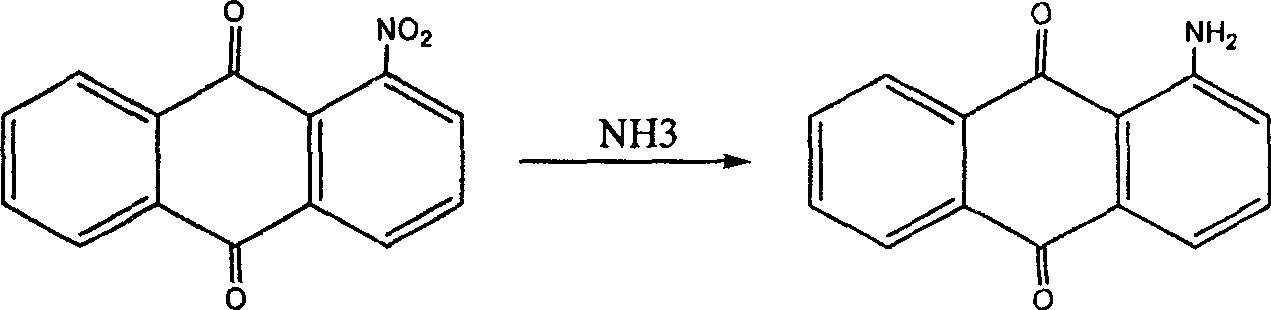

A technology of aminoanthraquinone and nitroanthraquinone, applied in chemical instruments and methods, preparation of organic compounds, chemical/physical/physicochemical fixed reactors, etc. Increased investment and other issues to achieve the effect of reduced equipment investment, stable product quality, and investment savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

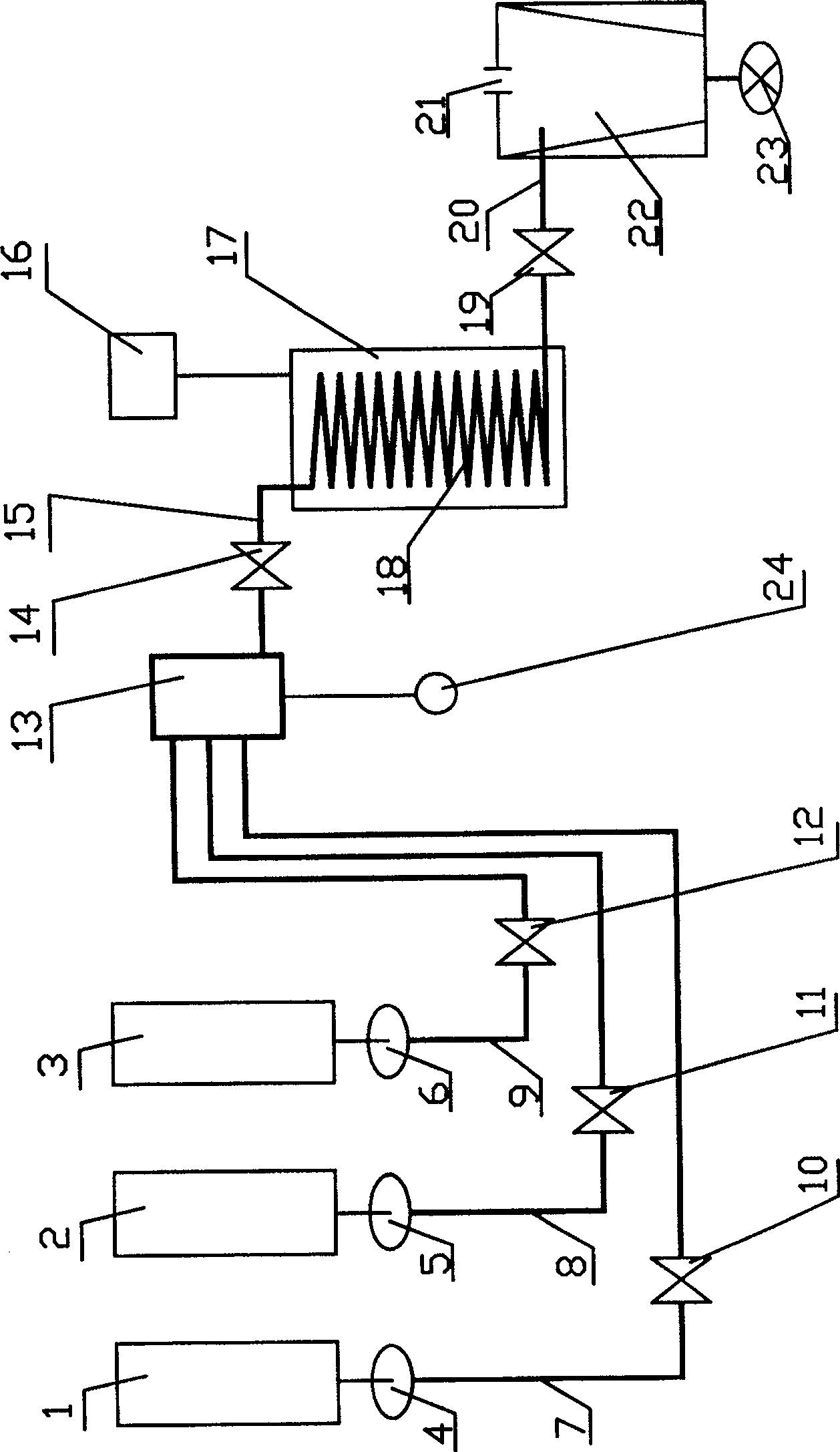

[0024] See attached figure 1 , the reaction device of the present invention comprises a metering tank 1 of 1-nitroanthraquinone, a metering tank 2 of a catalyst, a metering tank 3 of liquefied ammonia, a pipeline reactor 17 with a coil 18, a premixer 13, and a heater 16 is connected with pipeline reactor 17, and this heater 16 can select oil bath heater; Premixer 13 is connected with booster pump 24, and booster pump 24 can keep the pressure in the premixer 13 as required pressure. In order to facilitate the observation of the raw materials in the tank, the measuring tank 1 and the measuring tank 2 are designed as measuring tanks made of glass; the measuring tank 3 containing liquid ammonia is made of stainless steel, and the surface of the measuring tank 3 is provided with a glass liquid level gauge. The outlet of metering tank 1 is provided with high-pressure metering pump 4, and high-pressure metering pump 4 is connected to the inlet end of premixer 13 through pipeline 7; S...

Embodiment 2

[0028] The reaction device is as in Example 1. In metering tank 1, be the n-hexane solution (mass percentage concentration 40%) of 1-nitroanthraquinone, in metering tank 2, be the triethylamine solution (mass percentage concentration 1%) of ammonium bromide, in metering tank 3, be liquid ammonia. Adjust the flow ratio in the three metering tanks = 3.7:1:0.37 into the pipeline, control the reaction temperature at 150°C, the pressure at 10MPa, and maintain a material flow rate of about 0.3ml / s. The residence time of the ammonolysis reaction is about 20 minutes, and the rest of the operations are the same Example 1, the 1-aminoanthraquinone product was obtained with a yield of about 52%.

Embodiment 3

[0030]The reaction device is as in Example 1. In metering tank 1, be the xylene solution (mass percentage concentration 40%) of 1-nitroanthraquinone, be the n-octanol solution (mass percentage concentration 1%) of trimethylammonium bromide in metering tank 2, metering tank 3 Inside is liquid ammonia. Adjust the flow ratio in the three metering tanks = 5:1:0.6 into the pipeline, control the reaction temperature at 175°C, the pressure at 12MPa, and maintain a material flow rate of about 0.1ml / s. The ammonolysis reaction residence time is about 60 minutes, and the rest of the operations are the same Example 1. The 1-aminoanthraquinone product was obtained with a yield of 72%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com