Application of tinea alba fungi resisting fiber structure body

A technology of trichophyton and structure, which is applied in the field of anti-phytophyte fiber structure, can solve problems such as ignorance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0030] Dissolve the acrylonitrile-based polymer composed of 91.1% of acrylonitrile, 8.6% of methyl acrylate, and 0.3% of sodium methallylsulfonate prepared by conventional polymerization in 45% of sodium thiocyanate. -Da) aqueous solution to prepare a spinning dope with a polymer concentration of 12%. Use a known spinneret to extrude the stock solution into a 10% sodium thiocyanate aqueous solution at -3°C, wash with water, stretch, and heat-treat to make acrylic fiber (fiber A), and then, for the fiber Introduce silver into the medium, use 1% nitric acid aqueous solution to adjust 1000ml of silver nitrate aqueous solution adjusted to 20m·mol / l to pH3, put 100g of fiber A into the solution, treat at 98°C for 10 minutes, wash with water, dry, and then put into the adjusted Into 1000 ml of a 10 m·mol / l sodium oxalate aqueous solution, treated at 98° C. for 10 minutes, washed with water, and dried to prepare an acrylic fiber (fiber B) containing a silver compound.

manufacture example 2

[0032]Except using AN95%, the acrylonitrile polymer of vinyl acetate 5% composition, with the treatment time of silver nitrate aqueous solution being 30 minutes, other make the acrylonitrile fiber manufacture example 1 that contains silver compound similarly to contain silver acrylic fiber (fiber C) based on a compound.

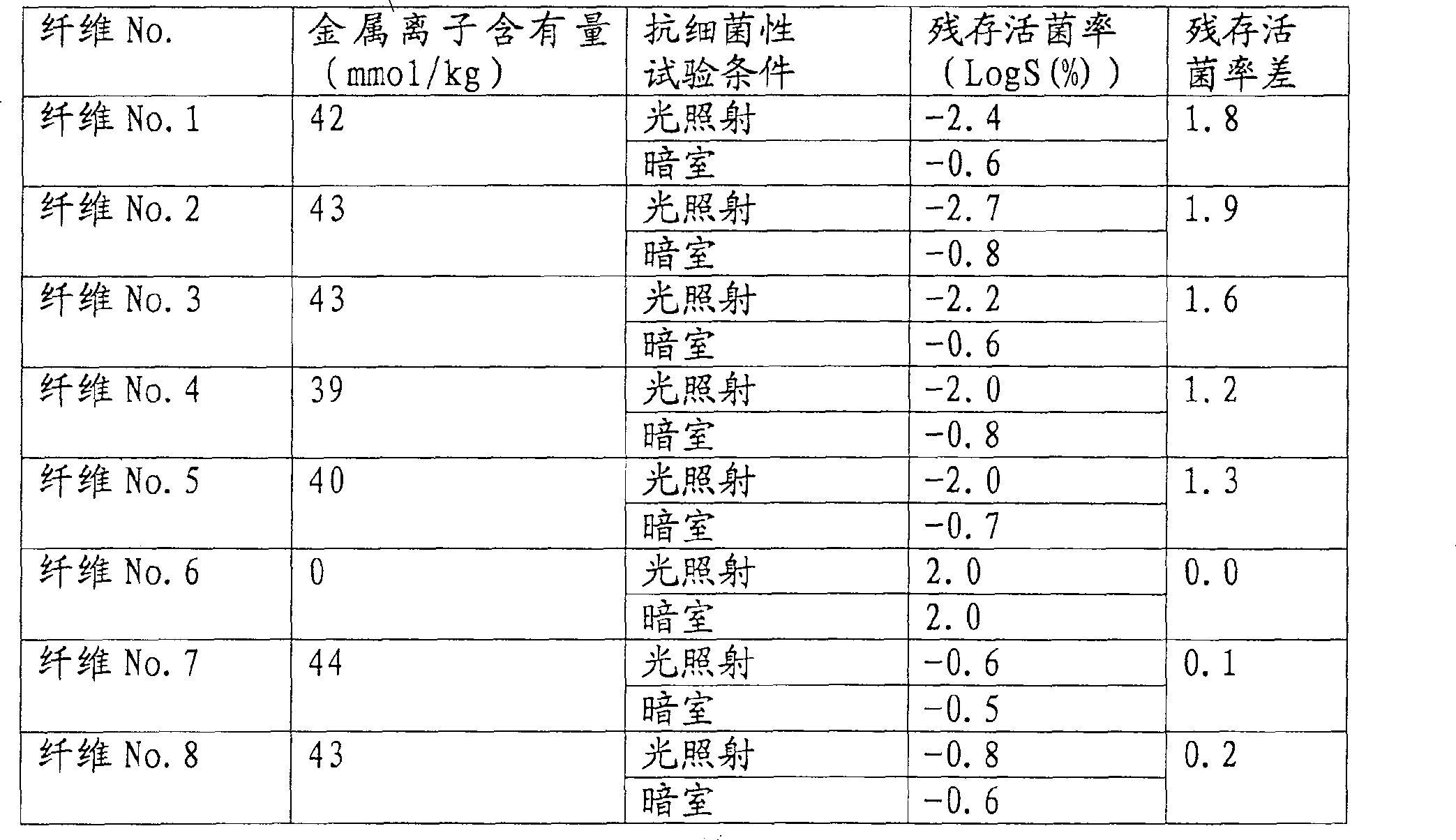

[0033] After soaking the acrylic fibers (fibers B and C) containing silver-based compounds prepared above in an aqueous solution whose pH is adjusted with nitric acid, remove the moisture, put them into an autoclave (when the heat treatment temperature exceeds 100°C) or dry them with hot air. machine (when the heat treatment temperature is below 100°C), heat treatment is carried out at the pH and temperature shown in Table 1, and six kinds of fibers of fiber No. 1-5 and 8 are made, and fiber No. 6 and 7 are silver-containing compounds respectively. The acrylic fiber (fiber A) of Production Example 1 and the acrylic fiber (fiber B) itself containing a silver-b...

Embodiment 1

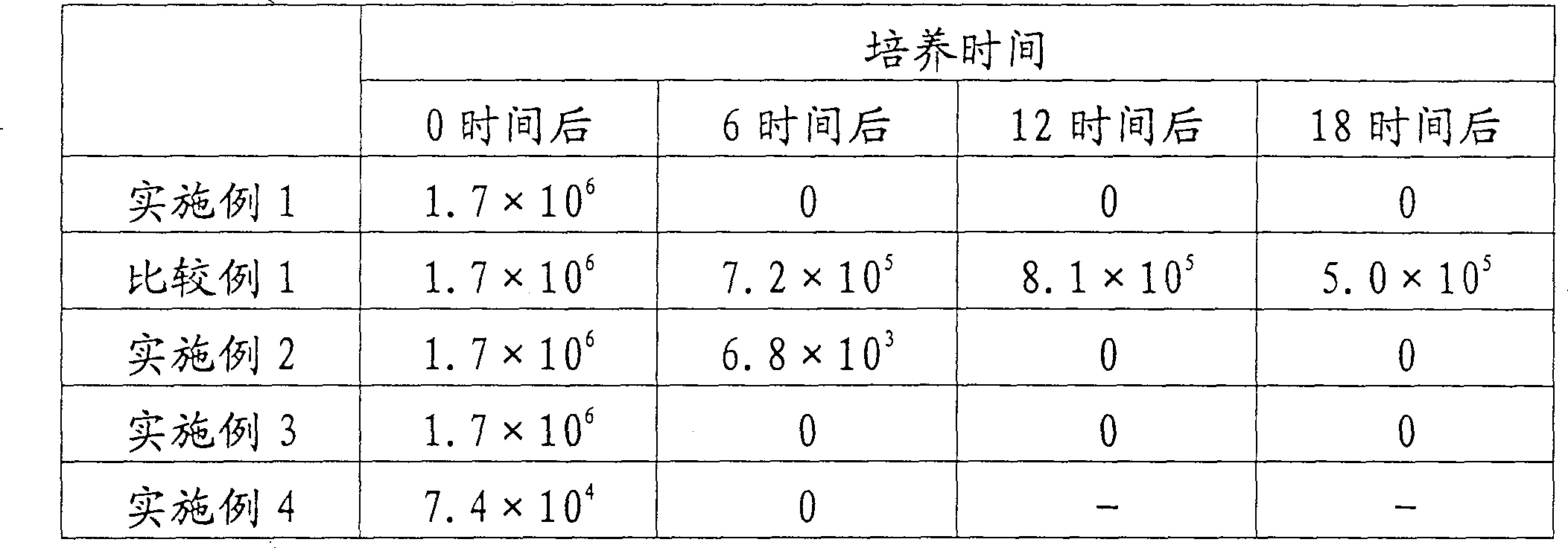

[0050] Embodiment 1, comparative example 1

[0051] As the silver-loaded acrylic fiber, the above-mentioned fiber No. 210% by weight, 40% of the acrylic fiber "K85-1.3T51" manufactured by Nippon Exlan Industry Co., Ltd., and the water-absorbent acrylic fiber "K626-1.7T51" manufactured by the company "50% by weight is blended, and the monofilament of metric count 1 / 10S is spun out according to the common method of spinning and weaving of synthetic fiber 2 inches, after continuing double-filament processing, make the yarn with the weight of 250g by creel circumference 200cm. The yarn was bulked at 100° C. for 15 minutes in an atmospheric box type steam treatment apparatus. The bulky yarn is rewound, and the weight per unit area is about 600g / m with a 3-gauge automatic flat knitting machine 2 Plain weave knitted fabric sample (Example 1). In Comparative Example 1, a knitted fabric sample was prepared in the same manner as in Example 1, except that the silver-loaded acrylic fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com