Method for making thick metal inductance in integrated circuit

A technology of integrated circuits and manufacturing methods, applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of metal line sidewall corrosion, voids, increase of polymers, etc., and achieve good electrical performance and process stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

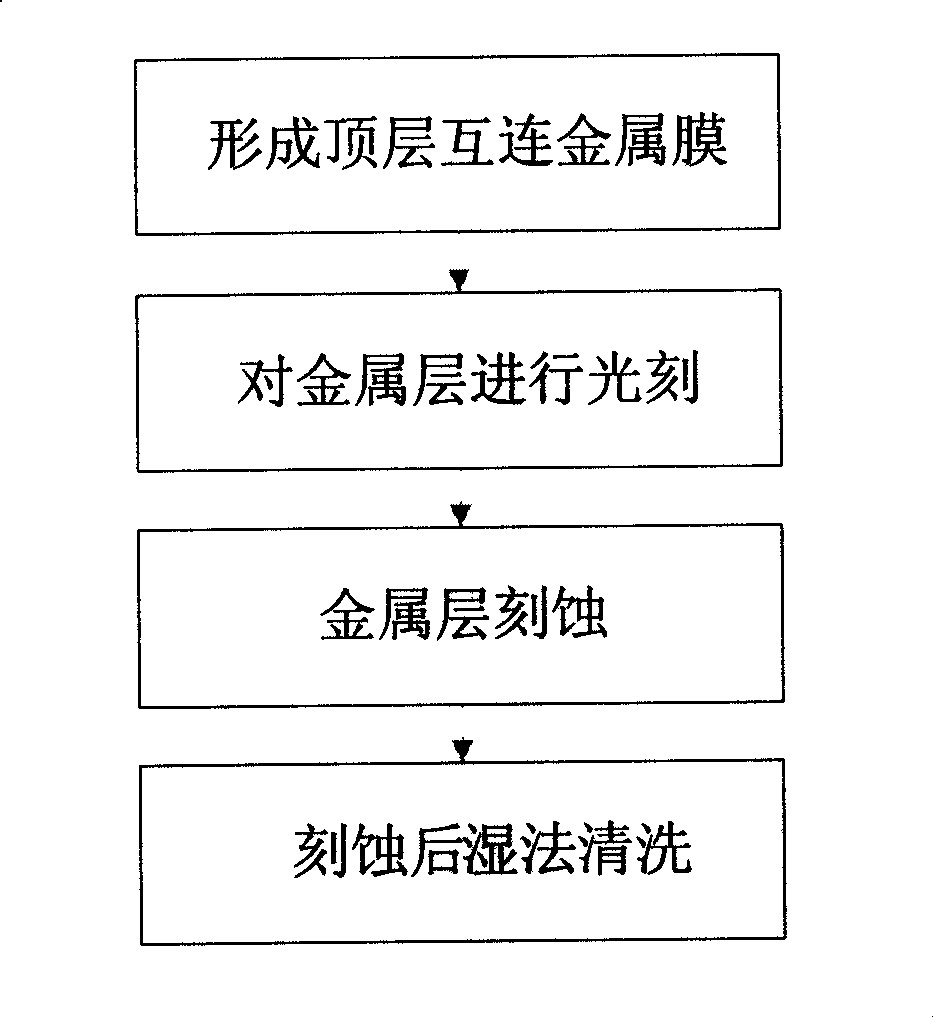

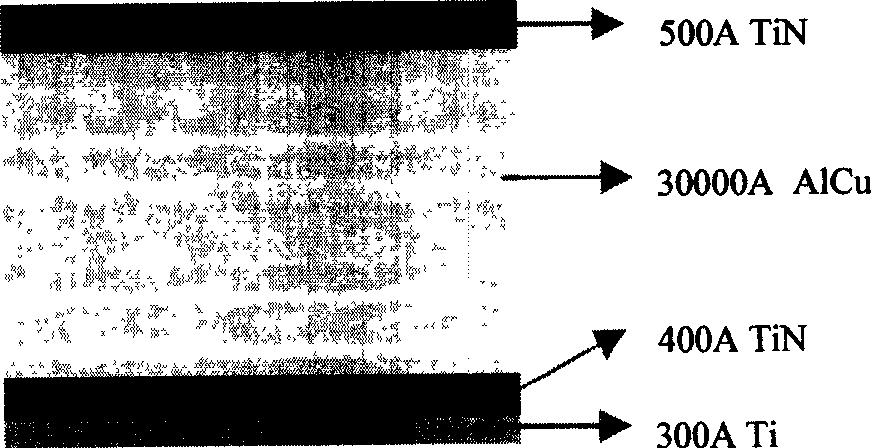

[0012] figure 1 It is a schematic flow chart of the manufacturing method of the thick metal inductor in the integrated circuit of the present invention. Such as figure 1 As shown, the present invention first adopts physical vapor deposition to sequentially deposit 300 angstrom Ti, 400 angstrom TiN, 30000 angstrom AlCu, and 500 angstrom TiN to form a 3 micron thick top layer interconnect thick metal film. Wherein, the schematic diagram of the thick metal layer structure can be found in figure 2 shown. Second, the thickness of AlCu can be 28000 angstroms to 32000 angstroms. A photoresist with a thickness of 4.0um is used as the metal pattern protective layer during etching. The third step, with Cl 2 and BCl 3 The thick metal layer is etched by dry etching method as the main etching gas, and the type of etching equipment used is DPS CENTURA5200 of Applied Materials for dry etching, and the dry etching is divided into three steps. Its process parameters refer to Figure 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com