Track type conveyor control device

A control device and conveyor technology, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of easy failure, heavy installation workload, easy wear and tear, and achieve the effect of simplifying the structure and avoiding wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

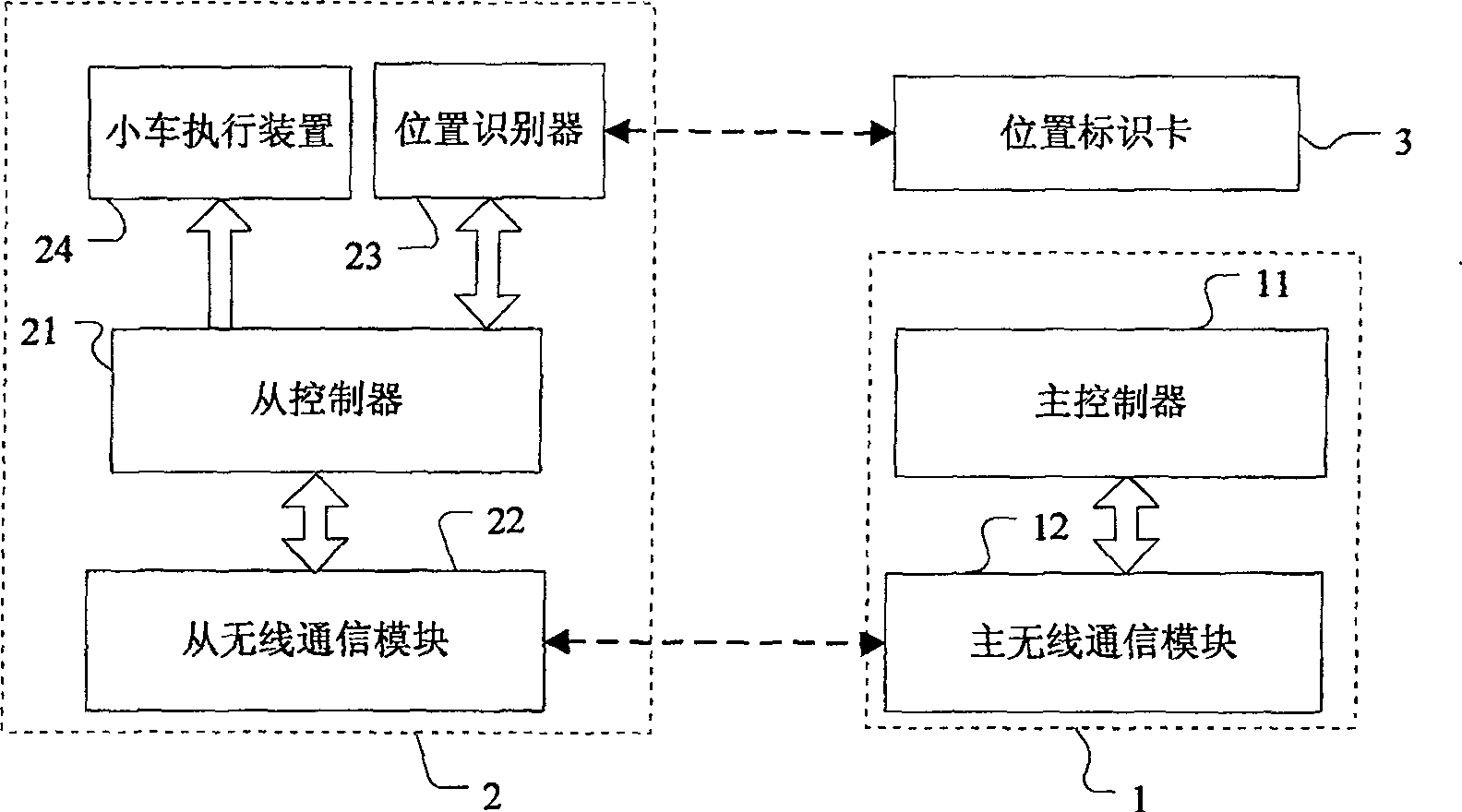

[0018] see figure 1 , figure 1 It is a structural block diagram of the present invention. The track conveyor control device of the present invention includes: a main control unit 1, several on-board control units 2 installed on each transport trolley, and a plurality of position identification cards 3 installed at different positions on the track. The main control unit 1 is composed of a main controller 11 and a main wireless communication module 12 connected through a serial interface; each vehicle-mounted control unit 2 is composed of a slave controller 21, a slave wireless communication module 22, a position identifier 23 and a car execution device 24 , and installed on a transport trolley; wherein, the slave controller 21 is respectively connected to the slave wireless communication module 22 and the position identifier 23 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com