Maintenance and clinker removal method of sub lance for converter dual blown from top and bottom, and equipment

A top-bottom combined blowing and converter technology, which is applied in the manufacture of converters, etc., can solve the problems of inflexible movement of the scraper-type slag scraper, affecting the operation of the sub-gun program of the converter, and incomplete cleaning of slag during maintenance. Converter smelting cycle, improving the operation rate of the sub-lance, and the effect of improving the operation rate of the converter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

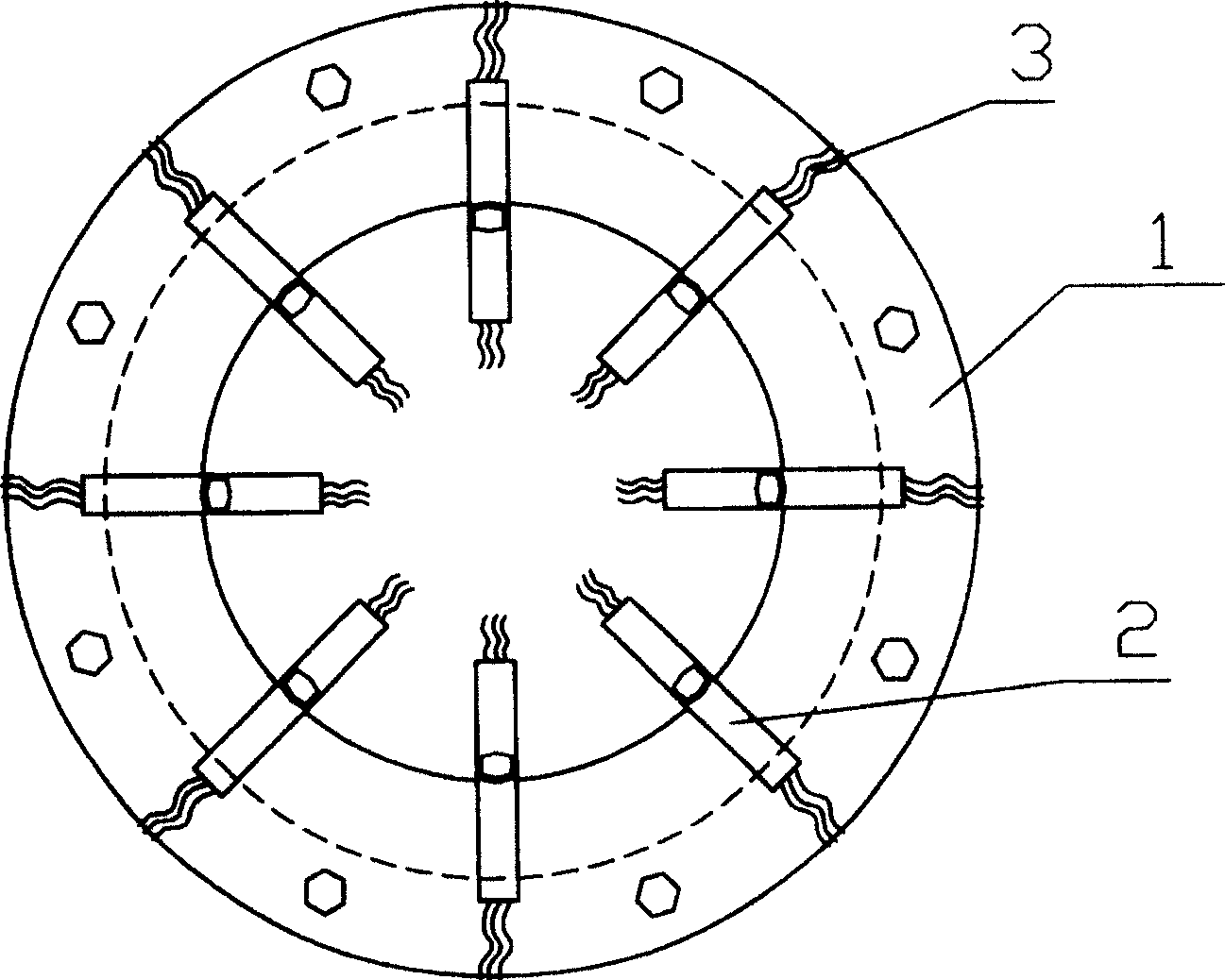

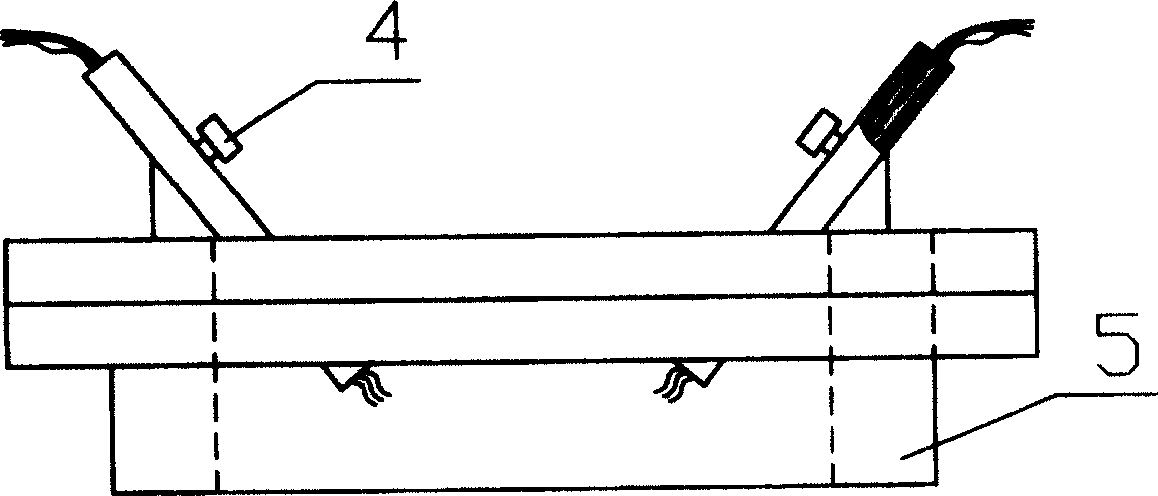

[0019] The preferred embodiment for realizing the present invention is: the embodiment of the 260t top-bottom combined blowing converter sub-lance maintenance and slag removal method, and the technical solution adopted is to carry out the test or lift the sub-lance after the sub-lance goes deep into the converter. The scraping brush removes the sticky residue, so the auxiliary gun can be maintained and cleaned in time to achieve normal use. To maintain the slag removal method, follow the steps below:

[0020] 1. Equipped with sub-gun test probe,

[0021] 2. The auxiliary gun goes deep into the converter for the first test,

[0022] 3. Lift the sub-gun after the test, and then wipe off the bonding residue on the sub-gun body and the probe equipment end,

[0023] 4. Equip the sub-lance with a test probe again, go deep into the converter for the second test, and then scrape the bonding slag of the sub-lance again.

[0024] 5. Lift the sub-gun after the test, and then scrape th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com