Chloroprene rubber polymer blend and its preparing method

A technology of neoprene and blends, which is applied in the field of neoprene blends and its preparation, can solve the problem of resistance to flex cracking of neoprene materials, deterioration of rubber process performance and physical and mechanical properties, neoprene There is no significant improvement in the resistance to flexing and cracking of rubber materials, and the effect of broad application prospects is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

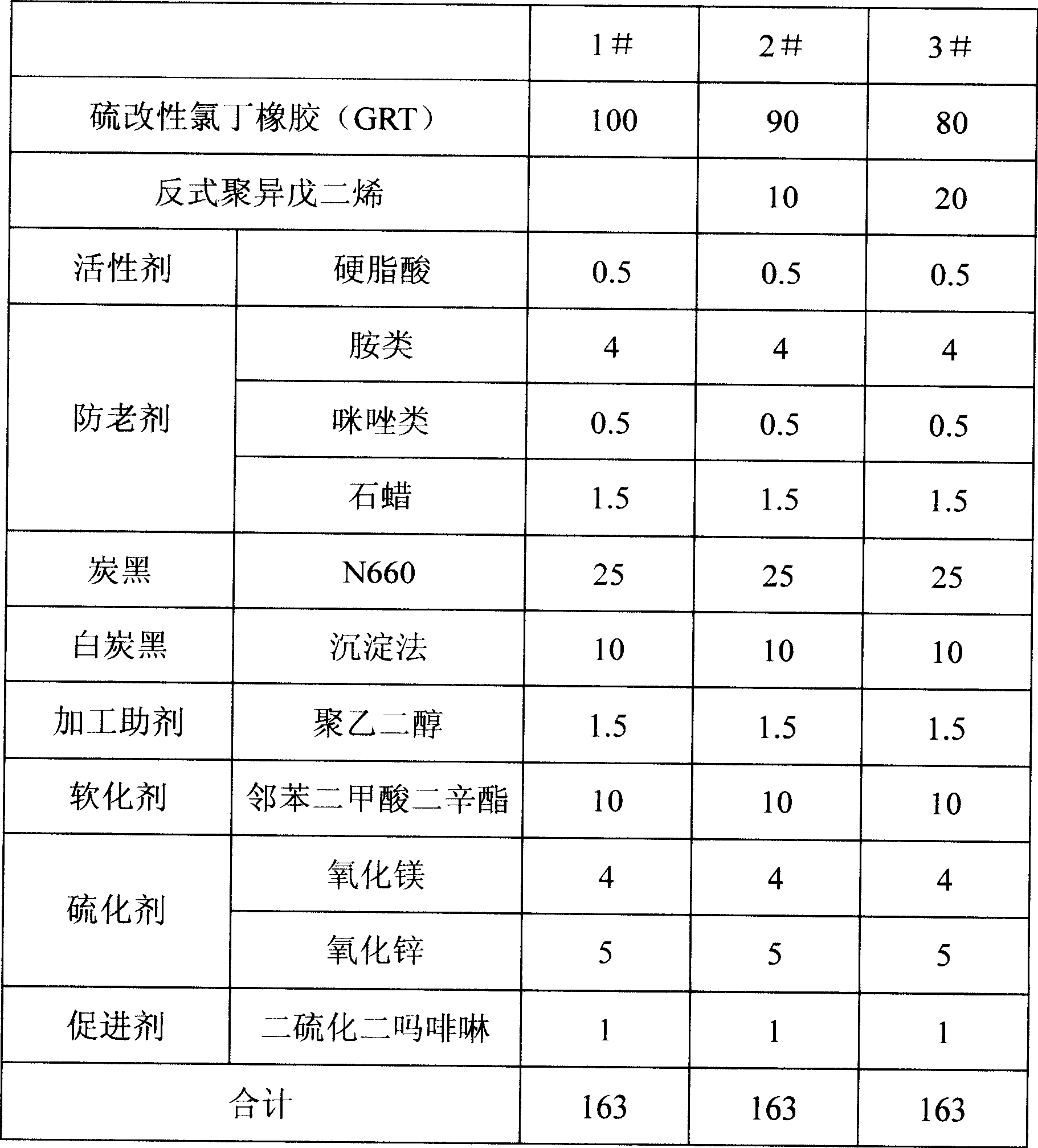

[0020] Example 1 Sulfur-modified chloroprene rubber and trans-polyisoprene blend

[0021] According to the formula batching of table 1, then prepare by following process:

[0022] 1. Plasticize trans-polyisoprene in the general rubber mixing equipment at a temperature range of 100°C for 2 minutes, and then blend with neoprene according to the ratio in Table 1;

[0023] 2. Prepare the rubber compound according to the conventional mixing process;

[0024] 3. After the mixed rubber is parked overnight, vulcanize at 150°C for 30 minutes according to the usual rubber vulcanization process.

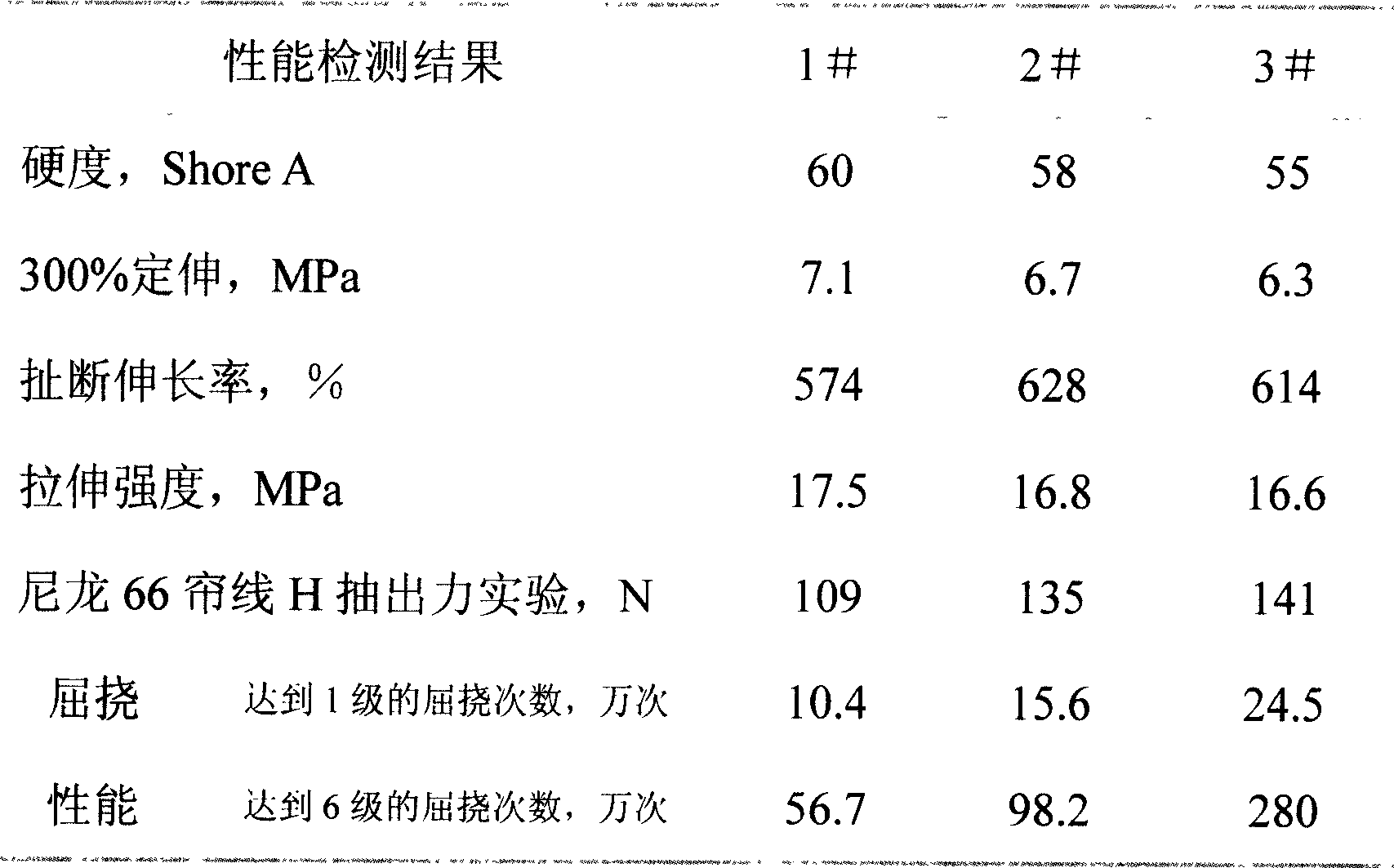

[0025] The physical and mechanical properties of the obtained vulcanizates are listed in Table 2. It can be seen from the table that after the sulfur-modified chloroprene rubber and trans-polyisoprene are blended (2#, 3# are neoprene and trans-polyisoprene blends, 1# is conventional chloroprene Rubber), the conventional properties of vulcanized rubber have little change, while the adhesion p...

Embodiment 2

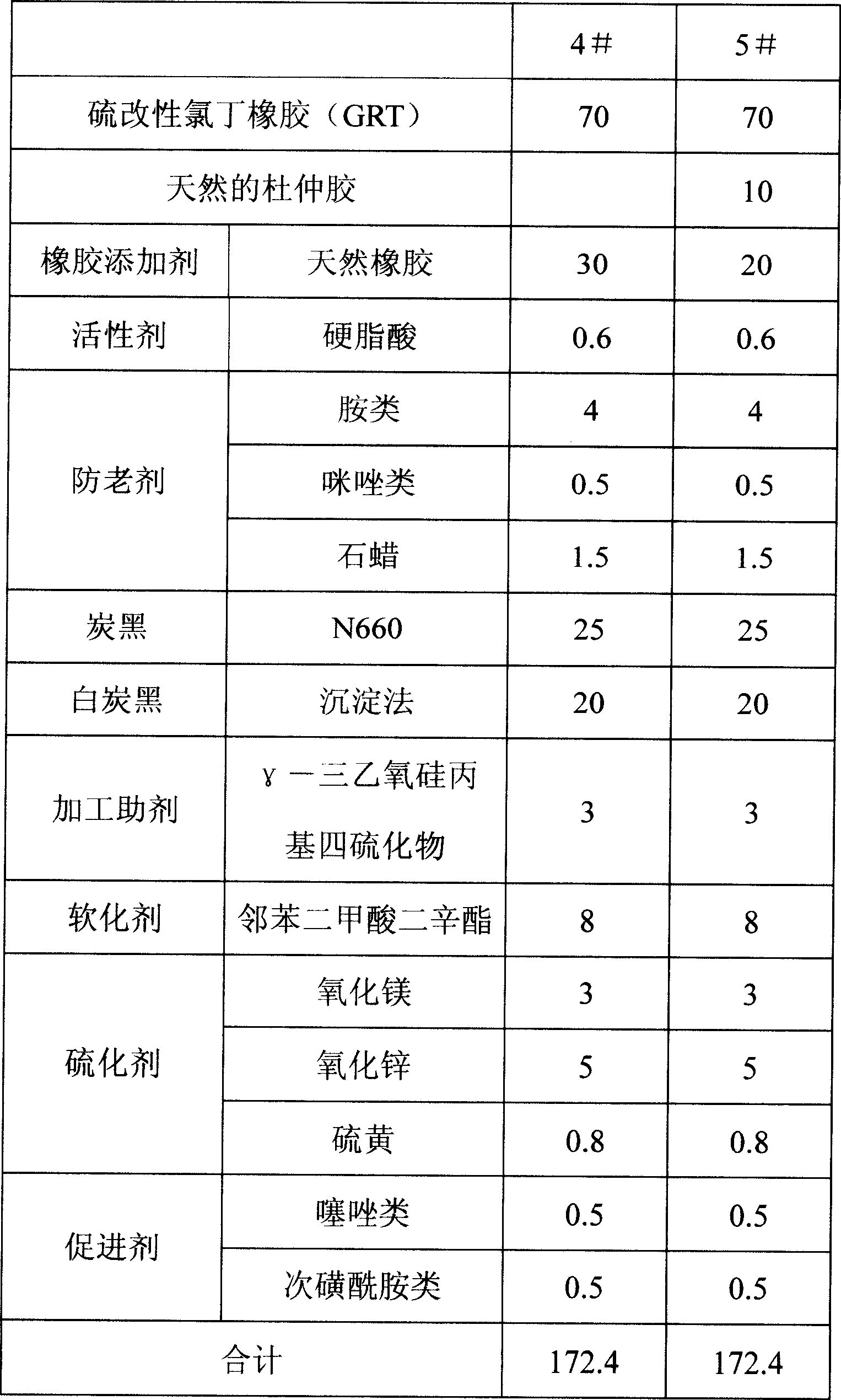

[0029] Embodiment 2 Sulfur-modified chloroprene rubber / natural rubber / natural Eucommia gum blend

[0030] According to the formula batching of table 3, then prepare by following process:

[0031] 1. Put the natural eucommia gum in the general rubber mixing equipment, masticate it for 30 minutes in the temperature range of 60 ℃, and then blend it with neoprene according to the ratio in Table 1;

[0032] 2. Prepare the rubber compound according to the conventional mixing process;

[0033] 3. After the mixed rubber is parked overnight, vulcanize at 150°C for 1 minute according to the usual rubber vulcanization process.

[0034] The physical and mechanical properties of the obtained vulcanizates are listed in Table 4. It can be seen from the table that after the blending of sulfur-modified neoprene / natural rubber and trans-polyisoprene, the general properties, brittleness temperature, and thermal aging properties of the vulcanizate did not change much, while the adhesive propert...

Embodiment 3

[0039] Example 3 Mercaptan-modified chloroprene rubber and gutta-percha blend

[0040] According to the formula batching of table 5, then prepare by following process:

[0041] 1. Masticate gutta percha rubber in the general rubber mixing equipment at a temperature range of 60-100°C for 2-30 minutes, and then blend with neoprene according to the ratio in Table 1;

[0042] 2. Prepare the rubber compound according to the conventional mixing process;

[0043] 3. After the mixed rubber is parked overnight, vulcanize at 150°C for 100 minutes according to the usual rubber vulcanization process.

[0044] The physical and mechanical properties of the obtained vulcanizates are listed in Table 6. It can be seen from the table that after blending mercaptan-modified chloroprene rubber with trans-polyisoprene, the conventional properties of the vulcanized rubber do not change much, while the adhesion performance and flex resistance performance are significantly improved.

[0045] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com