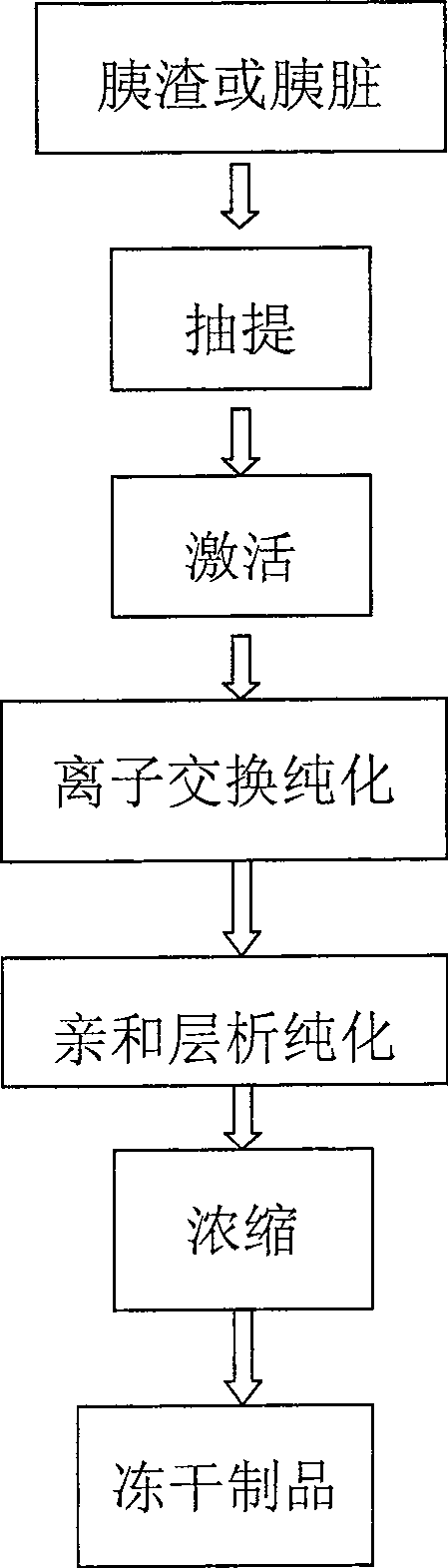

Method of extracting and purifying trypsin in pancrease slag

A technology of trypsin and pancreatic residue, applied in the field of enzymology, and its separation or purification, can solve problems such as pollution and complicated activation procedures of trypsin, reduce environmental pollution, reduce the risk of clogging and scaling, and be simple to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Extraction and activation of trypsin

[0031] Mix 250 g of pancreatic residue from which insulin has been extracted with 1000 mL of water, adjust the pH to 1.5 with 6 mol / L HCl solution, and stir for 2.5 hours; filter and collect the supernatant. Adjust the pH of the extracted supernatant to 6.0 with 10mol / L sodium hydroxide solution, and add calcium chloride to make Ca 2+ The final concentration is 10mmol / L, stir for 2.5 hours; filter, collect the supernatant, and operate at a temperature of 4-25°C.

Embodiment 2

[0032] Example 2 Extraction and activation of trypsin

[0033] Directly mix 1000mL of pH 2.0 hydrochloric acid and 250g of pancreatic residue, stir for 2.5hr, extract trypsin, filter, and collect the supernatant. Adjust the pH of the extracted supernatant to 7.0 with 10mol / L sodium hydroxide solution, and add calcium chloride to make Ca 2+ The final concentration was 10mmol / L, stirred for 2.5 hours; filtered, and the supernatant was collected. The operating temperature is 4-25°C.

Embodiment 3

[0034] Example 3 Extraction and activation of trypsin

[0035] Mix 250 g of pancreatic residue from which insulin has been extracted with 1000 mL of water, adjust the pH to 2.5 with 6 mol / L HCl solution, and stir for 2 hours; filter and collect the supernatant. Adjust the pH of the extracted supernatant to 7.0 with 10mol / L sodium hydroxide solution, and add calcium chloride to make Ca 2+ The final concentration was 20mmol / L, stirred for 3 hours; filtered, and the supernatant was collected. The operating temperature is 4-25°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com