Preparation method of epoxy resin base micron to nano grade pore gelatin

An epoxy resin and nano-scale technology, which is applied in the preparation of epoxy resin-based micro- to nano-scale pore gels, can solve the problems of discontinuity of filling system, pore size shrinkage of pore materials, unstable material properties, etc. Accurate and easy control, simple molding, excellent cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

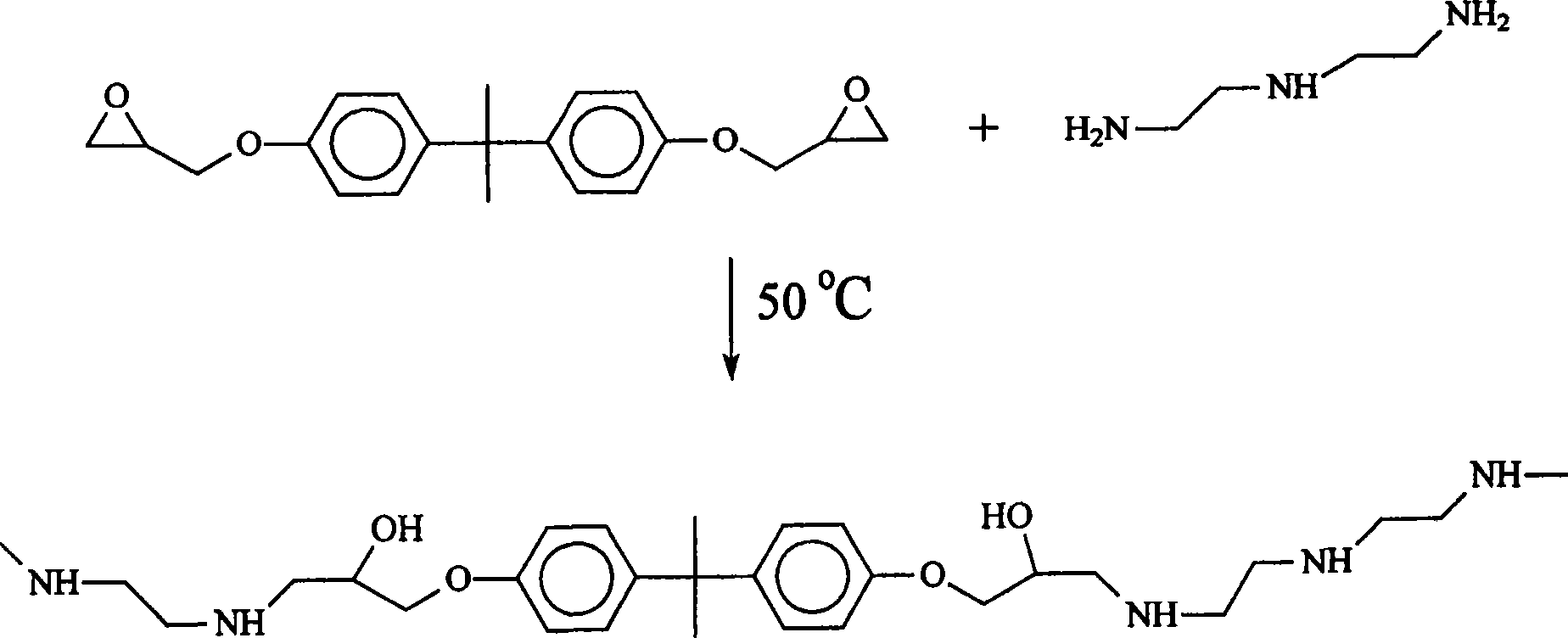

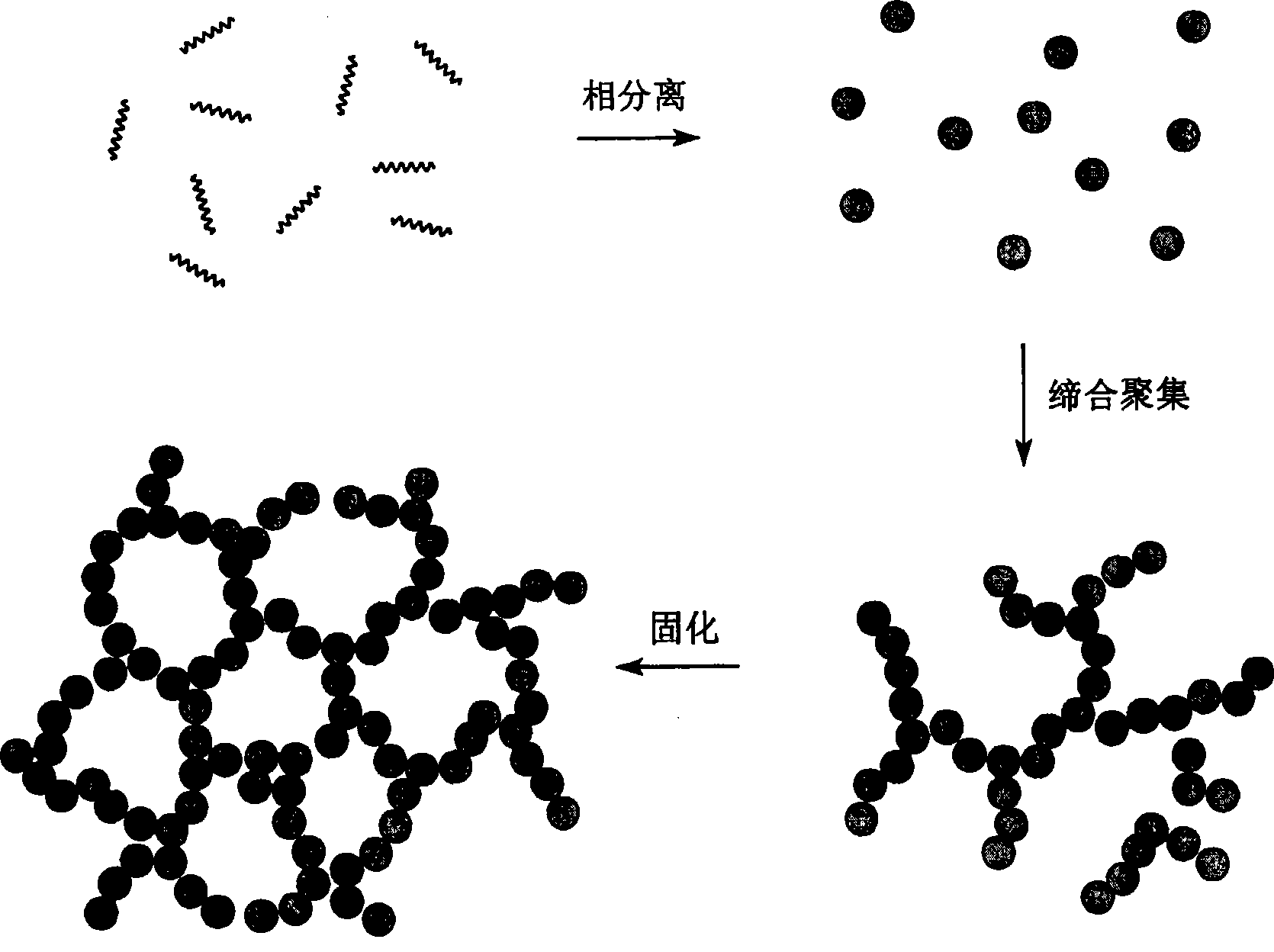

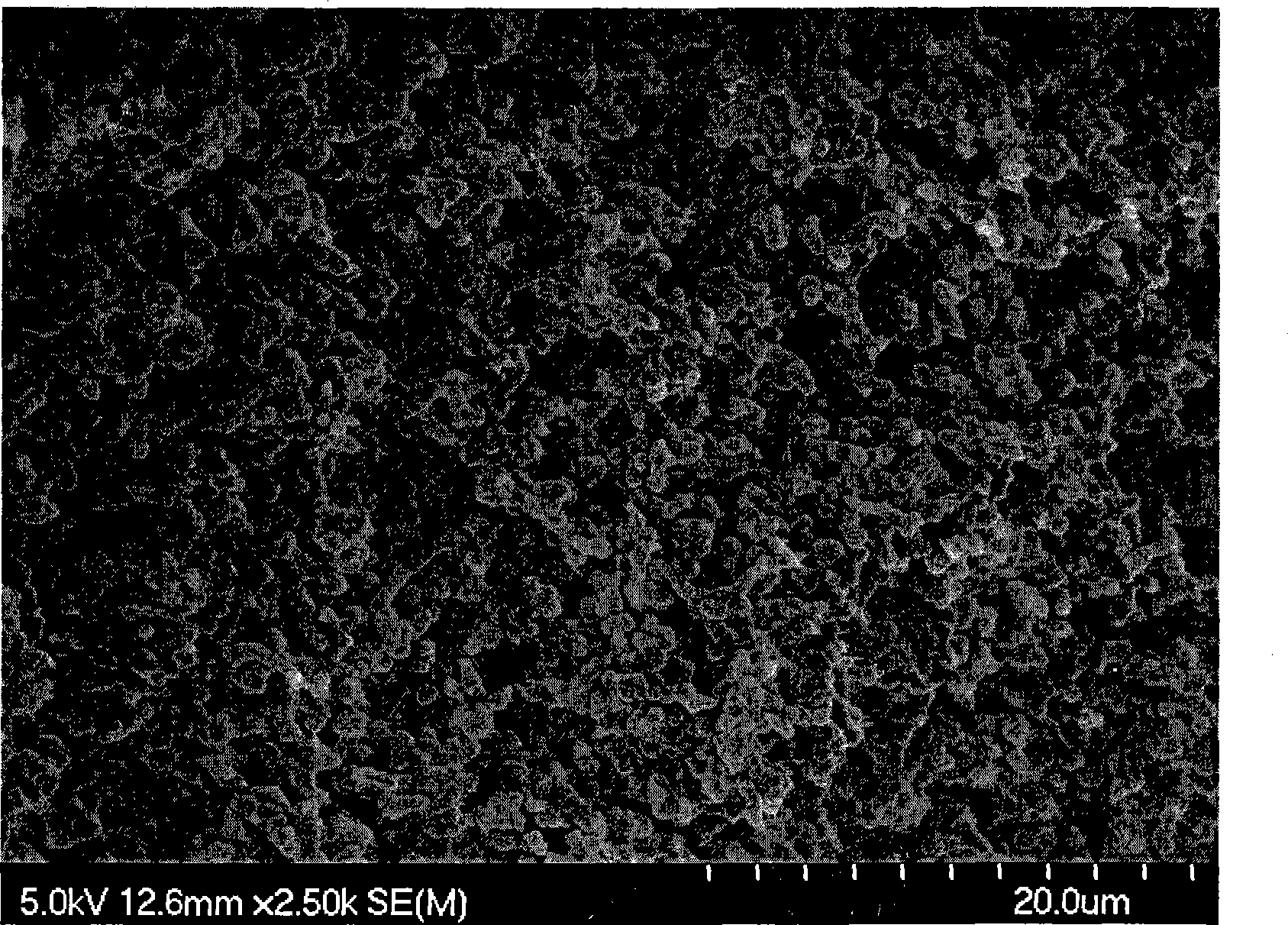

[0027] 10 grams of epoxy resin and 2.5 grams of diethylenetriamine were dissolved in 25 grams of polyethylene glycol 1000 medium to obtain a clear solution, polymerized at 50 ° C for at least 4 hours, the viscosity of the solution continued to increase, and then phase separation gradually occurred, forming A white gel that eventually solidifies into a block, the solid is placed in water and the polyethylene glycol is dissolved and removed to form a microporous gel. Its structure is as image 3 As shown, the pore diameter is shown in Table 1.

Embodiment 2~5

[0029] The weight of fixed epoxy resin and diethylenetriamine is constant, the weight of Polyethylene Glycol 1000 is changed into 25 grams, 40 grams, 50 grams, 60 grams respectively, all the other conditions and operation are identical with embodiment 1, make corresponding Microporous gel, the pore size is shown in Table 1.

[0030] Table 1:

[0031] Example 1 Example 2 Example 3 Example 4 Example 5 Epoxy resin (g) 10 10 10 10 10 Diethylenetriamine (g) 2.5 2.5 2.5 2.5 2.5 PEG1000(g) 25 30 40 50 60 Average pore size (μm) 0.22 0.45 0.78 1.2 1.6

Embodiment 6

[0033] The weight of fixed epoxy resin is 10 grams, the weight of polyethylene glycol 1000 is 30 grams, and triethylenetetramine is used instead, and the weight of amine is 3.0 grams, and the remaining conditions and operations are the same as in Example 1 to obtain microporous gel , and the pore diameters are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com