LED chip and method for preparing the same

An LED chip and chip technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems that the chip does not well solve the problems of light emitting efficiency and performance, complex bonding and separation processes, etc., to increase the luminous power of a single chip, The effect of increasing the light-emitting area and improving the light-emitting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and example the present invention is described in further detail.

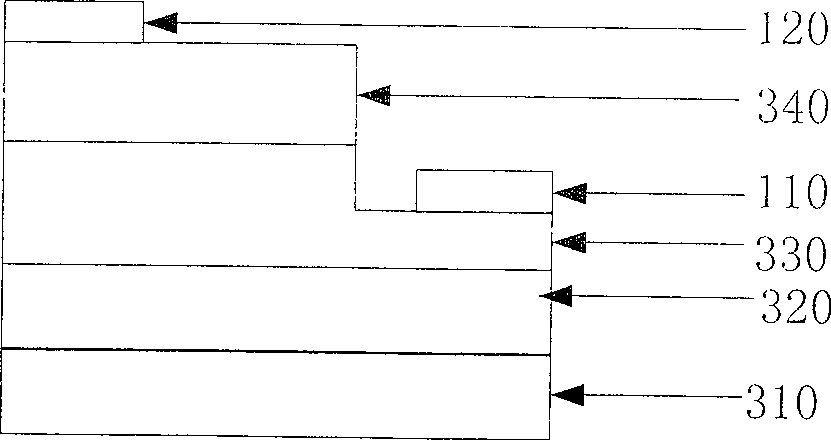

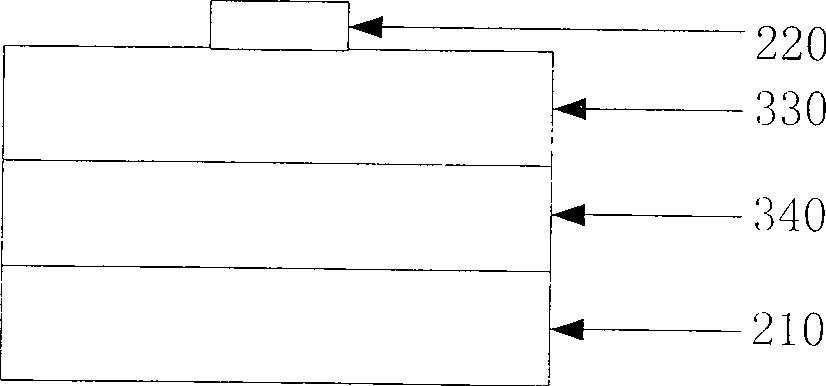

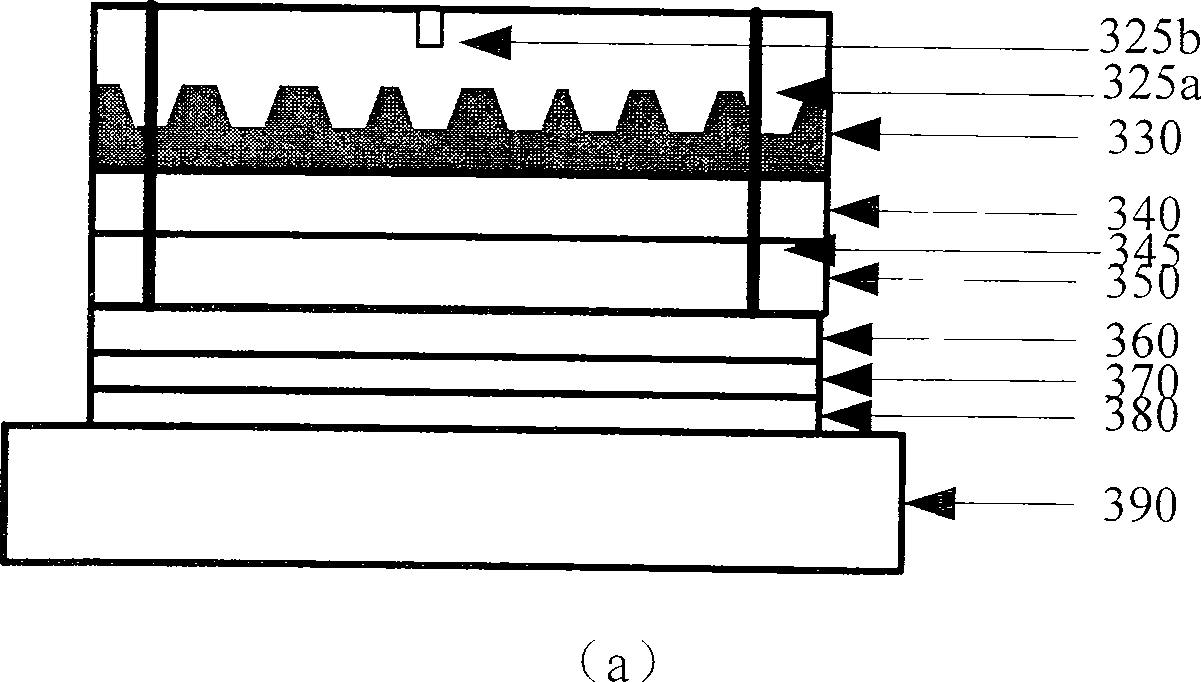

[0035] Such as image 3 As shown, the LED chip of the present invention is as follows from bottom to top: heat dissipation layer 390, bonding metal layer 380, insulating layer 370, P-type electrode 360, reflective layer 350, P-type GaN 340, N-type GaN 330 and N-type electrode, The upper surface of the N-type GaN layer 330 is a three-dimensional protrusion array, such as a conical or frustoconical structure, and the structure of the three-dimensional protrusions in the array will vary due to different process conditions. N-type electrode is made of ITO transparent electrode 325a and N electrode pad 325b, and the structure of the present invention also includes P electrode groove 345, and P electrode groove is after etching out 4 P electrode grooves at four corners of chip structure, from N The P-type GaN is etched onto the P-type GaN.

[0036] Such as Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com