Sectional drive combined type fire grate system

A combined furnace and segmented drive technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as insufficient drying, agglomeration, and incomplete dispersal, so as to shorten drying time and improve combustion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

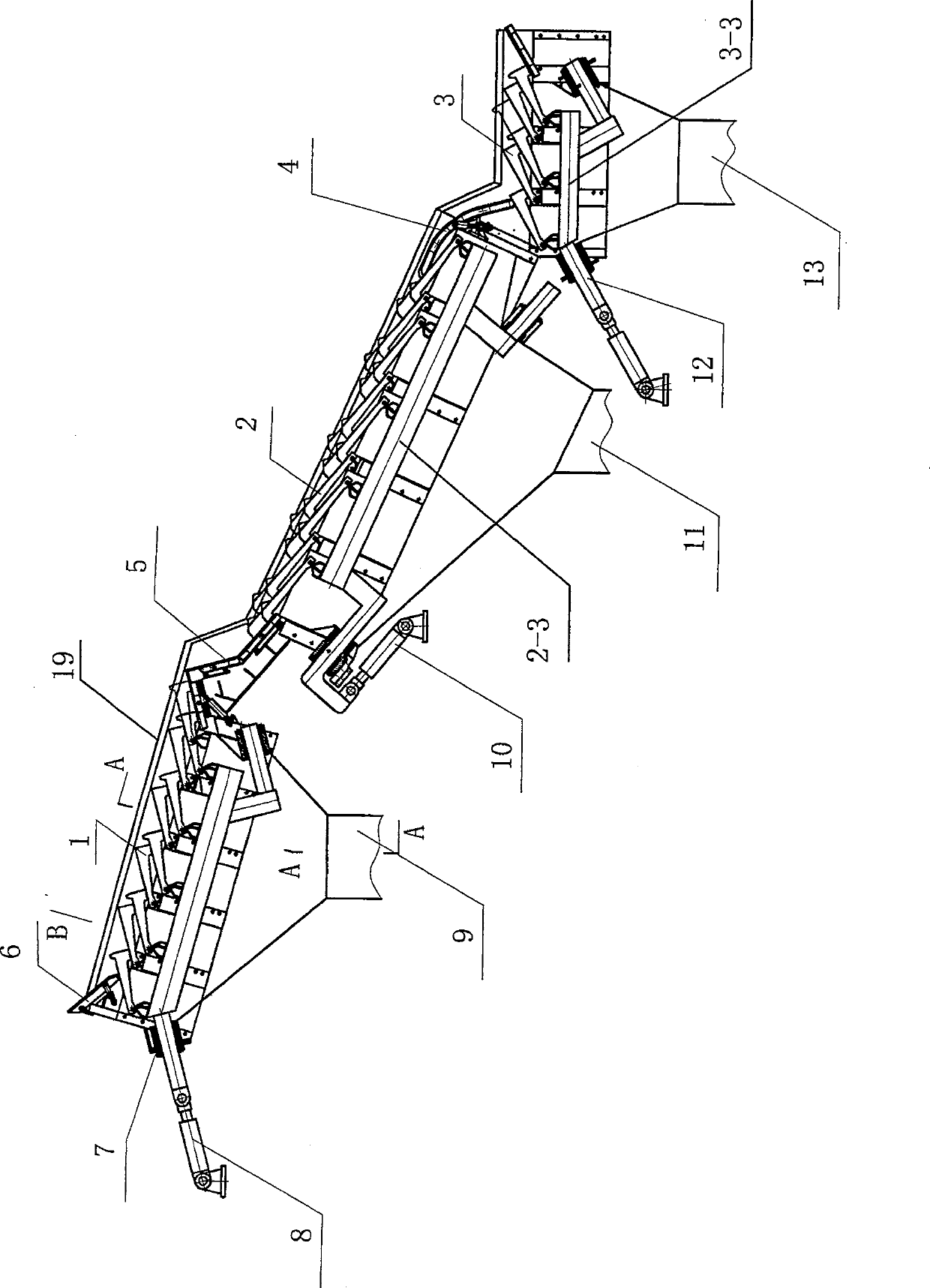

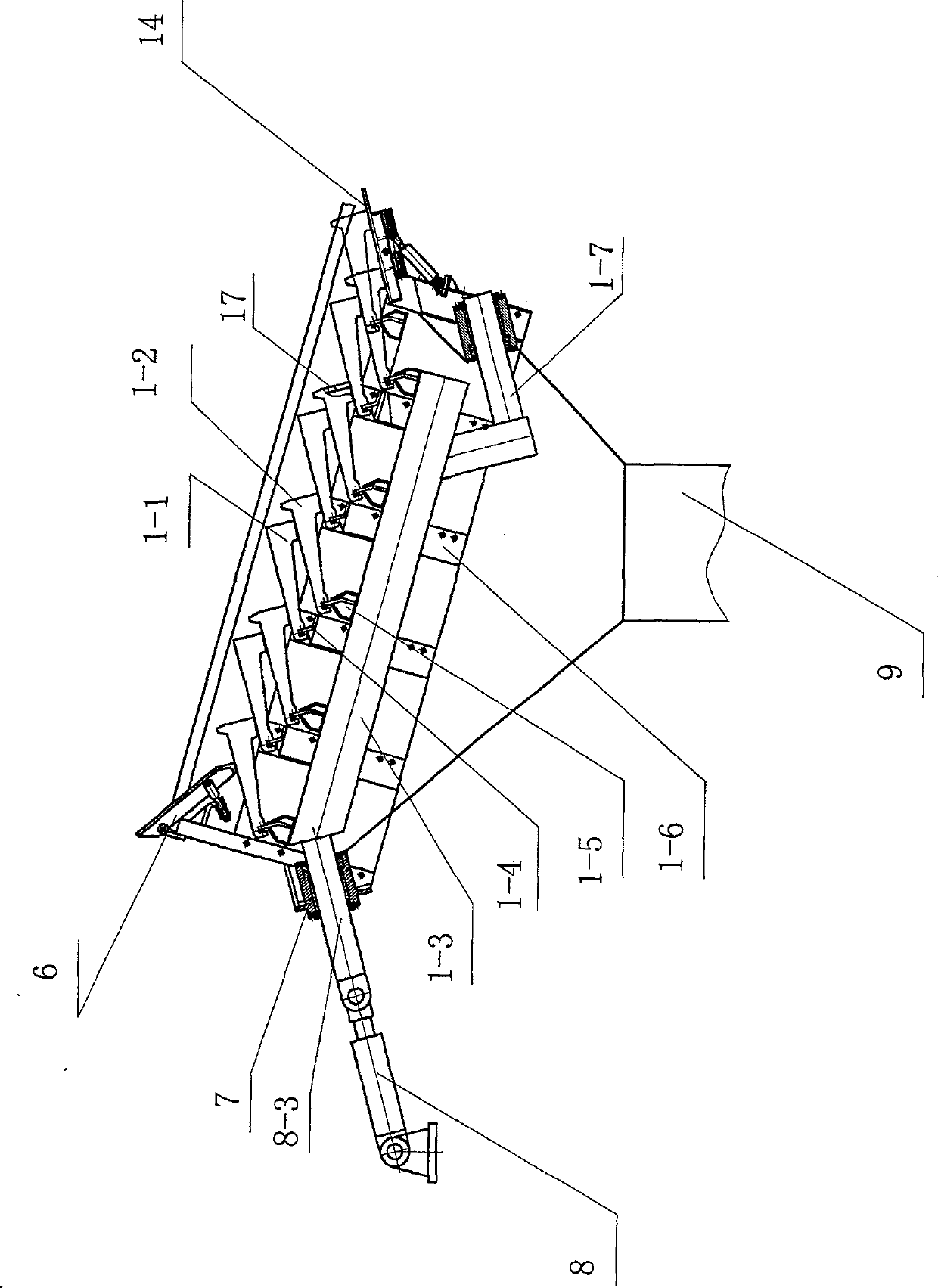

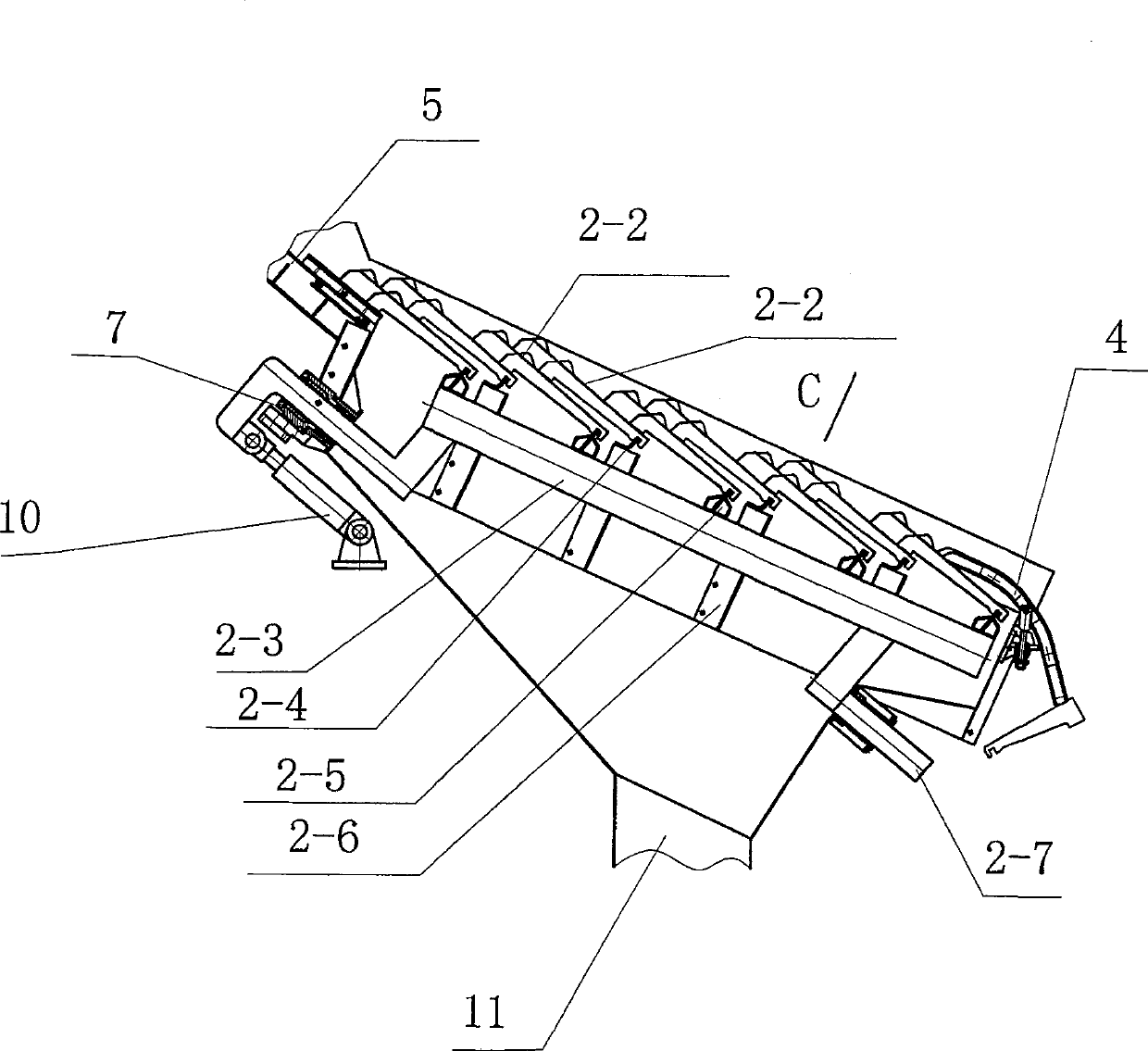

[0039] Please see figure 1 , a segmented drive composite grate system, the incineration grate is divided into drying section 1, burning section 2, and burning section 3 from high to low, among which drying section 1 is the highest point, and burning section 3 is the lowest point , The combustion section 2 is located between the drying section 1 and the ember section 3 . There is a height difference between each section, wherein the angle between the inclined plane formed by the connection line of the head of the grate section 1 in the drying section and the horizontal plane is 0-18°, preferably 15°. The included angle between the inclined plane and the horizontal plane is 22°~28°, preferably 26°. The connecting lines of the grate piece heads of the embers section 3 form a plane parallel to the horizontal plane. The heads of the grate pieces on the drying section 1 and the embers section 3 are all towards the low point of the grate, so that the moving direction of the movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com