Method for forming finely porous metal thin film through jet ink technique

A metal film and micro-hole technology, applied in conductive pattern formation, electrical components, printed circuit manufacturing, etc., can solve the problem of easy entry of plating solution into micro-holes, and achieve the effects of improving peeling, reducing use and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

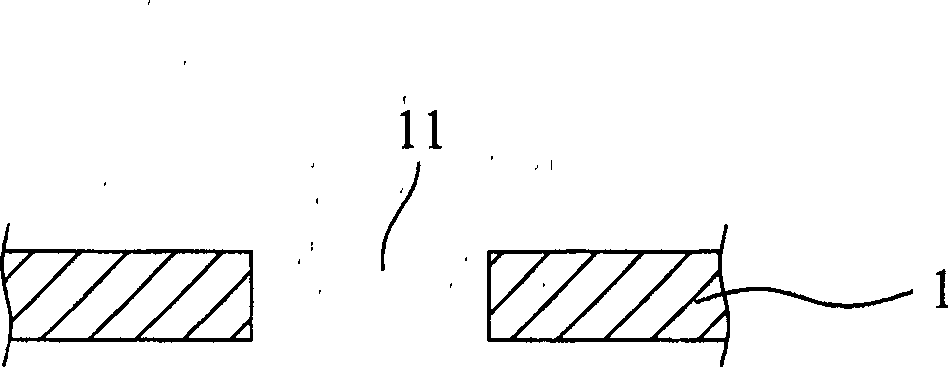

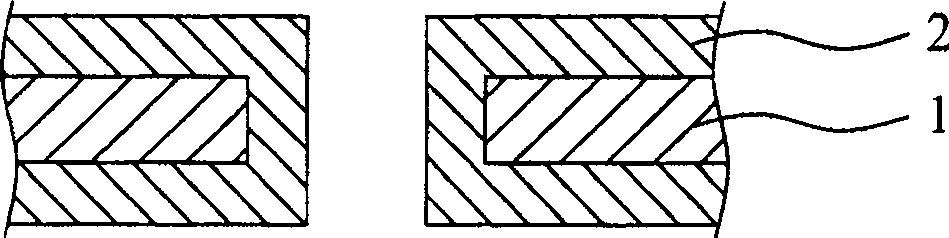

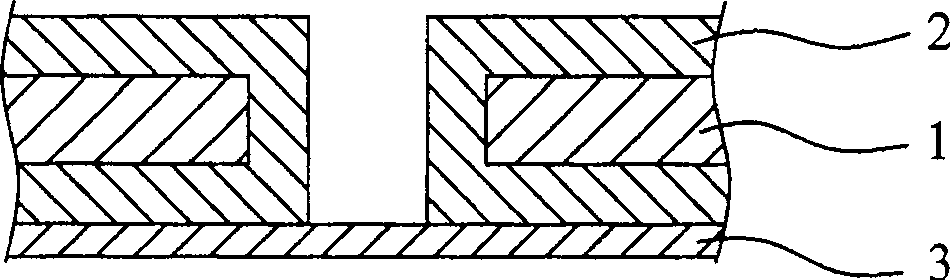

[0066] Figure 1A ~ 1G Shown is a schematic diagram of applying the present invention to substrate micropores, Figure 4 Shown is the flow chart of the method for applying the present invention to substrate micropores, and Figure 5A , 5B Shown is a detailed flow chart of step 102 of the method for applying the present invention to the micropores of the substrate. According to the method provided by the present invention for forming a metal film in the micropores by the inkjet method, it includes the following steps:

[0067] Step 101, firstly, a substrate 1 (Substrate) is provided, and the substrate 1 is provided with micropores 11, please refer to Figure 1A shown. This substrate 1 is selected from the combination of glass substrate, polyester (PET) substrate, organic glass fiber (FR-4) substrate, flexible organic glass fiber substrate (Flexible FR-4) and polyimide substrate (Polyimide) one.

[0068] Step 102, perform surface treatment on the surface of the substrate 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com