Method for producing direct methanol fuel cell positive pole catalysts

A methanol fuel cell and catalyst technology, applied in battery electrodes, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low electrocatalytic activity, battery performance degradation, catalyst poisoning, etc., and achieve uniform dispersion and electroactivity The effect of increased area and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Ultrasonically disperse carbon nanotubes in an aqueous solution of ruthenium trichloride, wherein the mass ratio of carbon nanotubes: ruthenium is 1:0.02, and the ultrasonic time is 0.5 hours, with a drop rate of 9ml / h, 1ml / mg Ru The amount of 30% hydrogen peroxide was added dropwise to the system, and the mixture was refluxed at 75°C for 3.5 hours, then filtered, washed, and dried at 80°C to obtain hydrated ruthenium dioxide-supported carbon nanotubes;

[0022] (2) Disperse the hydrated ruthenium dioxide-loaded carbon nanotubes prepared in step (1) in ethylene glycol, ultrasonically disperse, and add chloroplatinic acid, wherein the mass ratio of ruthenium: platinum: ethylene glycol is 1:0.5 : 200, the pH value was adjusted to 6.5, and the mixture was refluxed at 125°C for 1.5 hours, then filtered, washed, and vacuum-dried at 65°C to obtain a high-efficiency direct methanol fuel cell anode catalyst Pt / RuO 2 ·xH 2 O / CNTs.

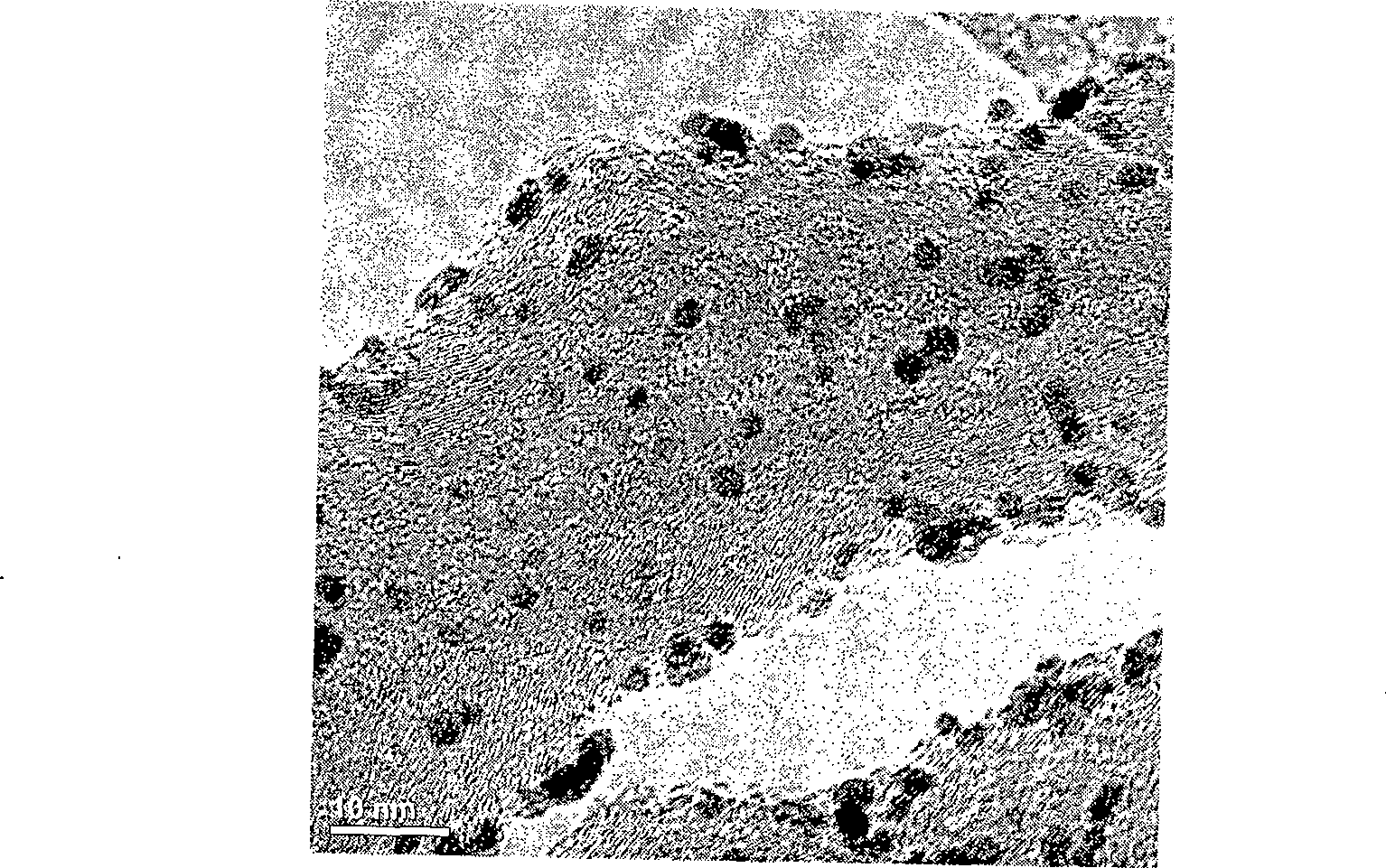

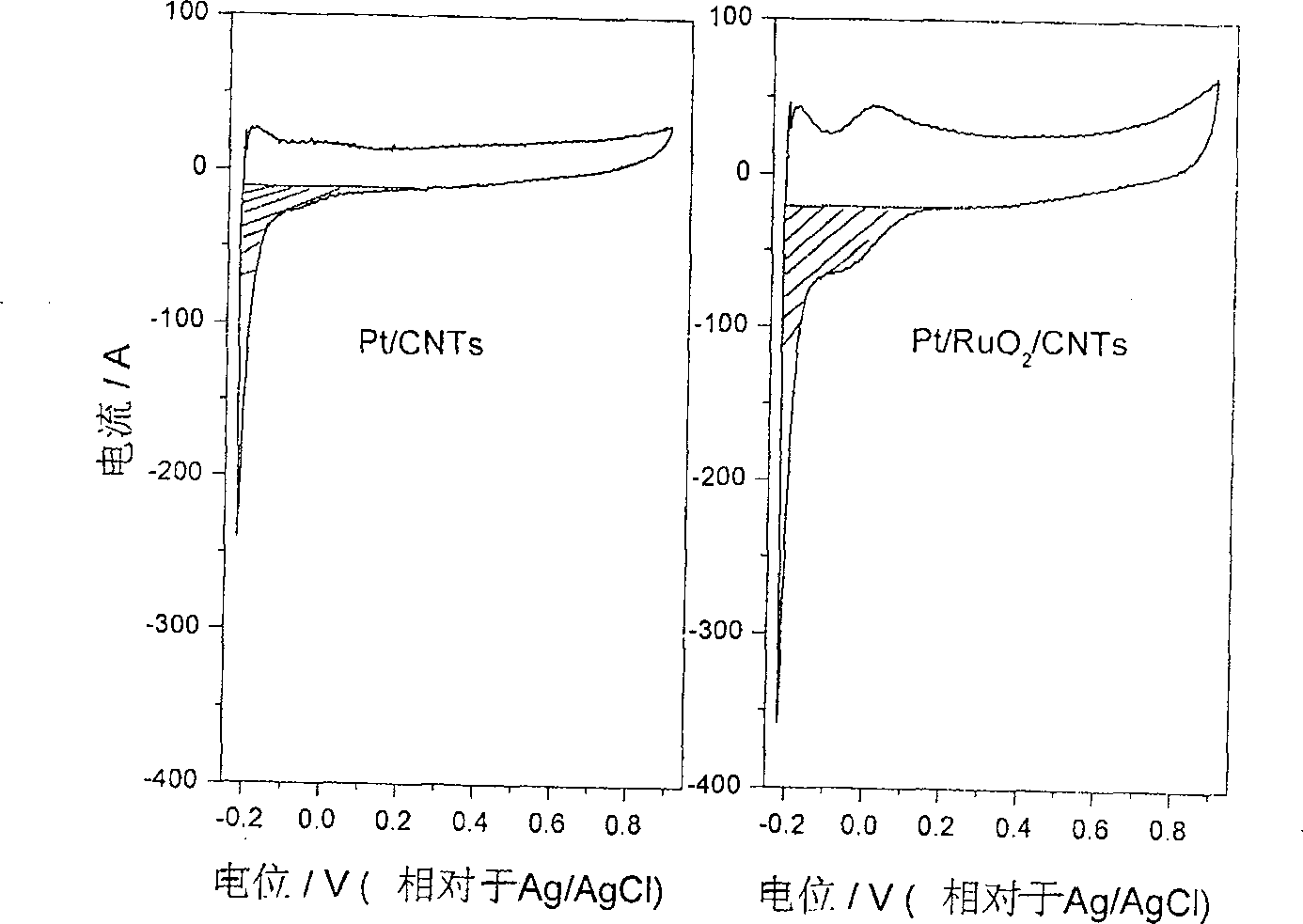

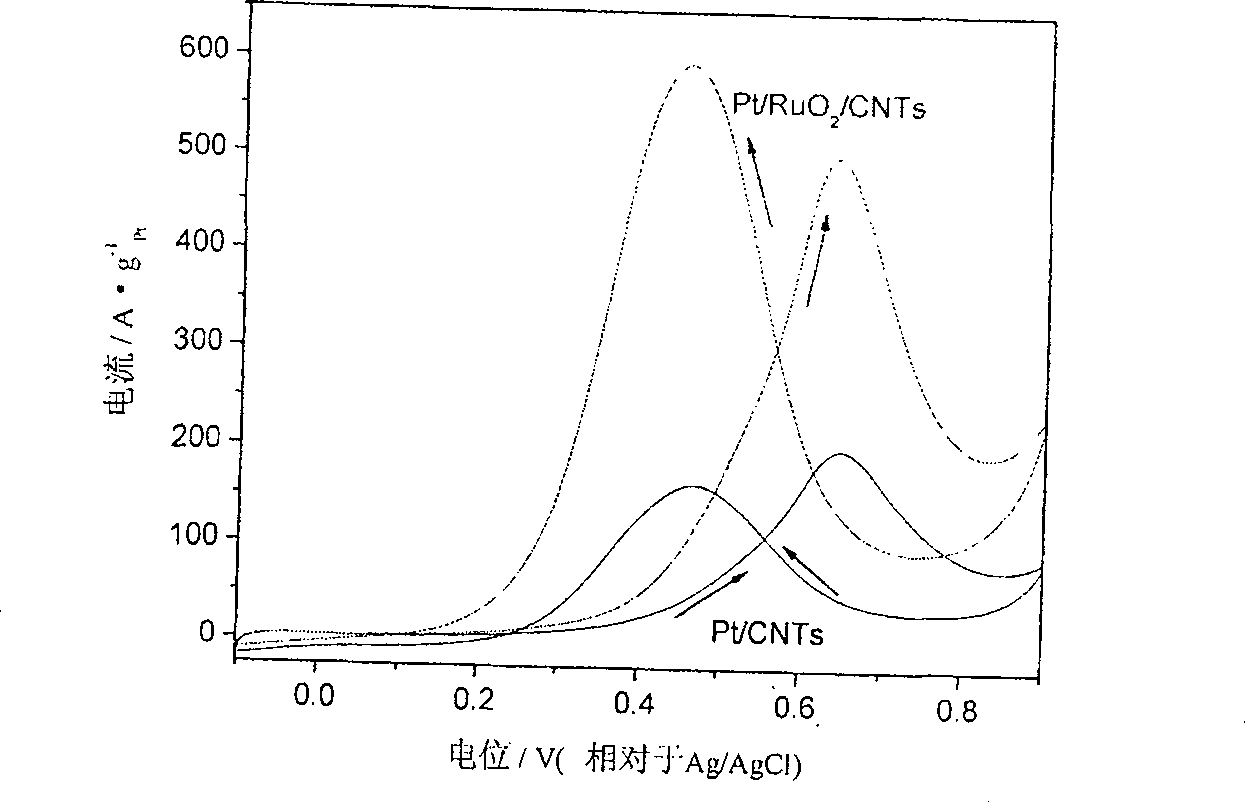

[0023] Prepared Pt-RuO 2 ·xH 2 The tra...

Embodiment 2

[0025] (1) Ultrasonically disperse carbon nanotubes in an aqueous solution of ruthenium trichloride, wherein the mass ratio of carbon nanotubes: ruthenium is 1:0.04, the ultrasonic time is 1 hour, and at a dropping rate of 10ml / h, 1.5ml / h mg Ru The amount of 30% hydrogen peroxide was added dropwise to the system, and the mixture was refluxed at 80°C for 4 hours, then filtered, washed, and dried at 90°C to obtain hydrated ruthenium dioxide-supported carbon nanotubes;

[0026] (2) Disperse the hydrated ruthenium dioxide-loaded carbon nanotubes prepared in step (1) in ethylene glycol, ultrasonically disperse, and add chloroplatinic acid, wherein the mass ratio of ruthenium: platinum: ethylene glycol is 1:1 : 250, adjust the pH value to 7, reflux at 130°C for 2 hours, then filter, wash, and vacuum dry at 70°C to prepare the high-efficiency direct methanol fuel cell anode catalyst Pt / RuO 2 ·xH 2 O / CNTs.

[0027] Prepared Pt-RuO 2 ·xH 2 The electroactive area test results of O / ...

Embodiment 3

[0029] (1) Ultrasonic dispersion of carbon nanotubes in an aqueous solution of ruthenium trichloride, wherein the mass ratio of carbon nanotubes: ruthenium is 1:0.1, ultrasonic time is 2 hours, with a drop rate of 15ml / h, 1.7ml / h mg Ru The amount of 30% hydrogen peroxide was added dropwise to the system, and the mixture was refluxed at 78°C for 4.2 hours, then filtered, washed, and dried at 110°C to obtain hydrated ruthenium dioxide-supported carbon nanotubes;

[0030] (2) Disperse the hydrated ruthenium dioxide-supported carbon nanotubes prepared in step (1) in ethylene glycol, ultrasonically disperse, add chloroplatinic acid, wherein the mass ratio of ruthenium: platinum: ethylene glycol is 1:1.5 : 280, adjust the pH value to 6.8, reflux at 132°C for 2.2 hours, then filter, wash, and vacuum-dry at 68°C to prepare the high-efficiency direct methanol fuel cell anode catalyst Pt / RuO 2 ·xH 2 O / CNTs.

[0031] Prepared Pt-RuO 2 ·xH 2 The test results of electrocatalytic oxida...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com