Overflow device for desulfurizing adsorption tower

A desulfurization absorption tower and overflow device technology, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of flow blockage of overflow pipes and abnormal discharge of flue gas, and save water resources and energy. , The effect of preventing the abnormal discharge of flue gas and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

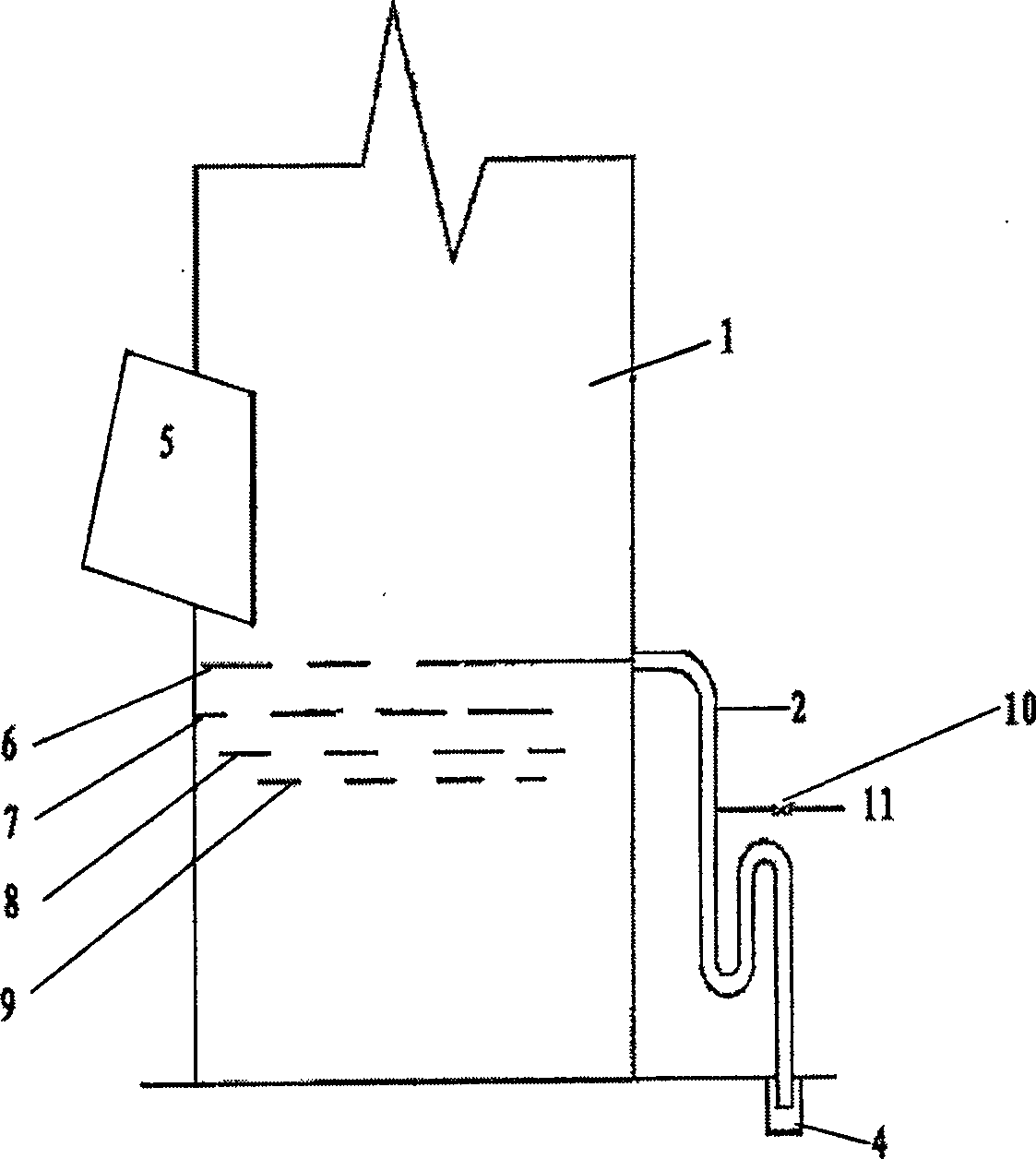

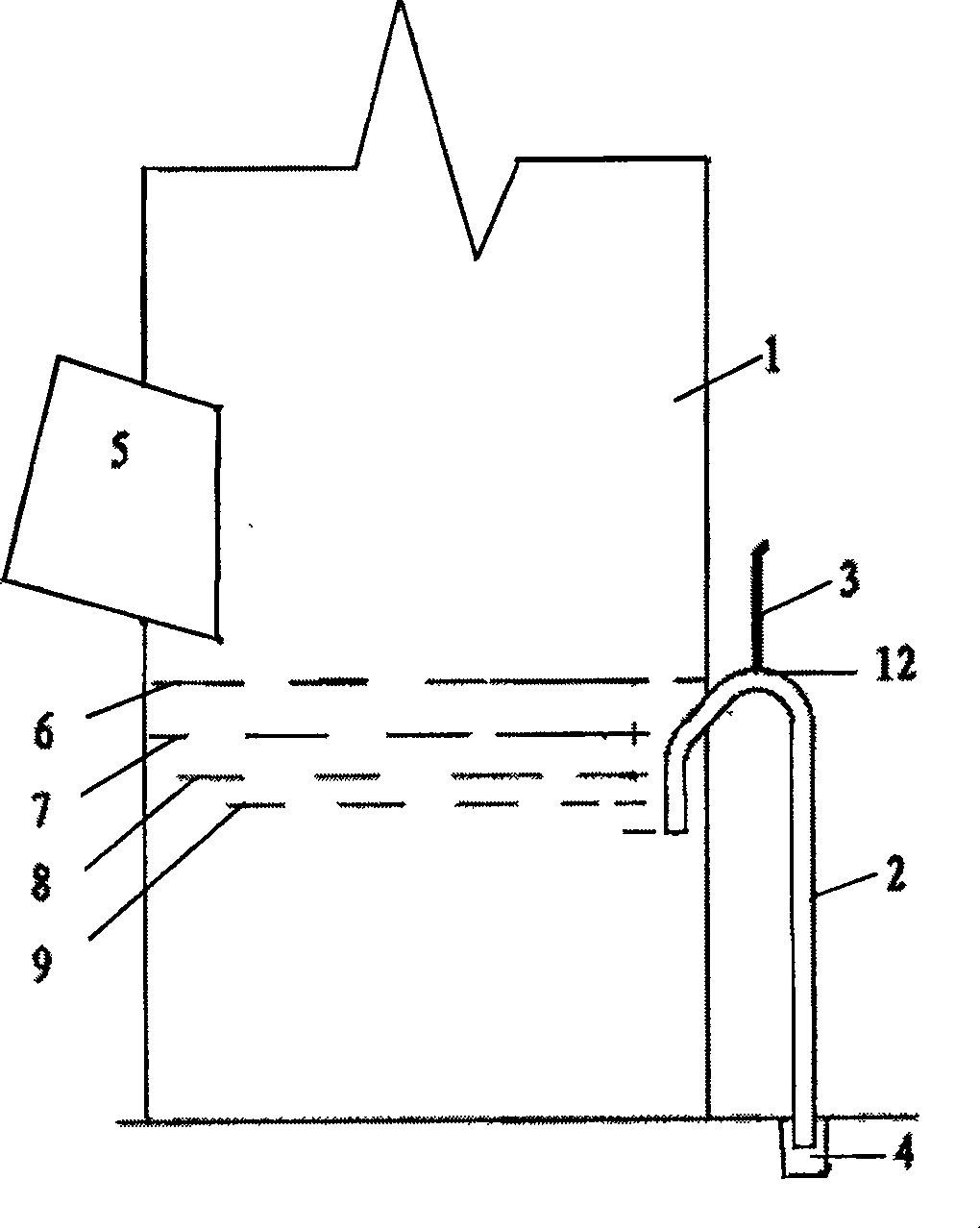

[0020] In this embodiment, the suction port of the overflow pipe 2 (DN250: pipe diameter 250mm, the same below) is 500mm lower than the lowest liquid level of the slurry in the tower for normal operation in the tower, and then 45° upwards to the absorption tower, the overflow pipe The highest center elevation is the same as that of the overflow liquid level of the absorption tower, and the overflow pipe outside the tower is connected to the trench 4 vertically downwards. In order to prevent the occurrence of siphon phenomenon, an anti-siphon pipe 3 (DN100) is installed on the top of the overflow pipe 1.

[0021] The overflow device is simple and easy to implement, does not require flushing water, does not block the overflow pipe, and saves investment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com