Sludge phase-splitting slaking method of water treatment plant

A sewage treatment plant and sludge technology, which is applied in the field of sludge waste pollution control in sewage plants, can solve problems such as poor economy, unfavorable sludge reduction, and reduced sludge dewatering effect, and achieve the effect of reducing the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

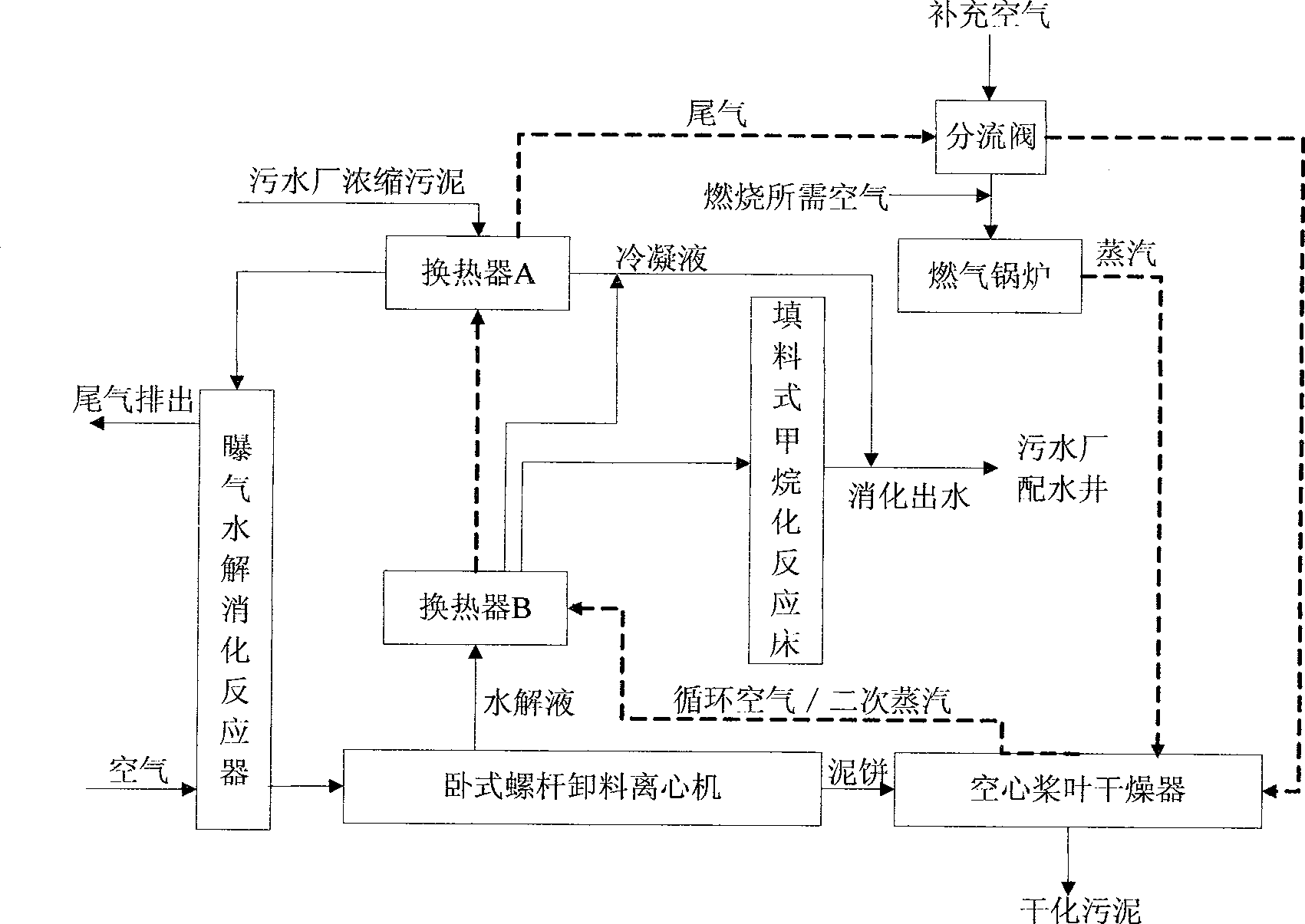

[0027] The following is a sewage treatment plant with a sludge dry solid production of 20t / d (equivalent to a daily sewage treatment of 100,000 m 3 sewage treatment capacity) as an example, the specific implementation of the present invention is introduced in conjunction with the accompanying drawings.

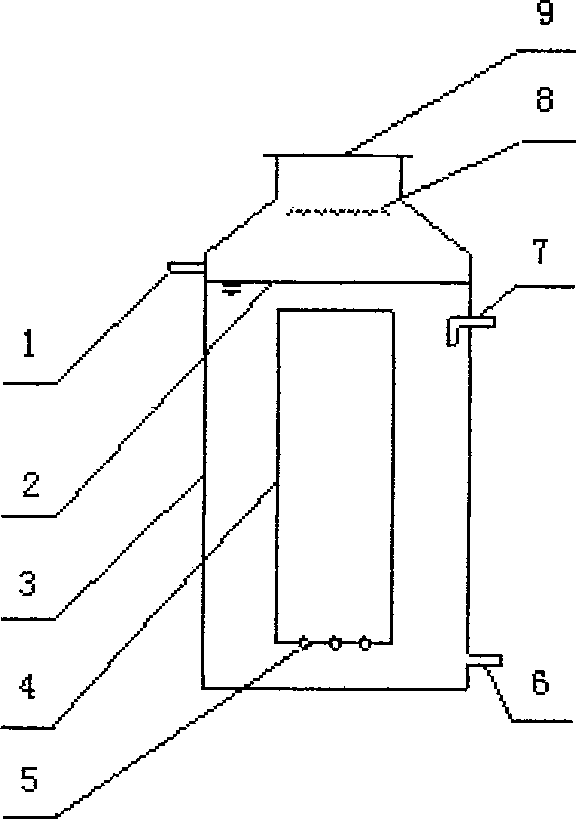

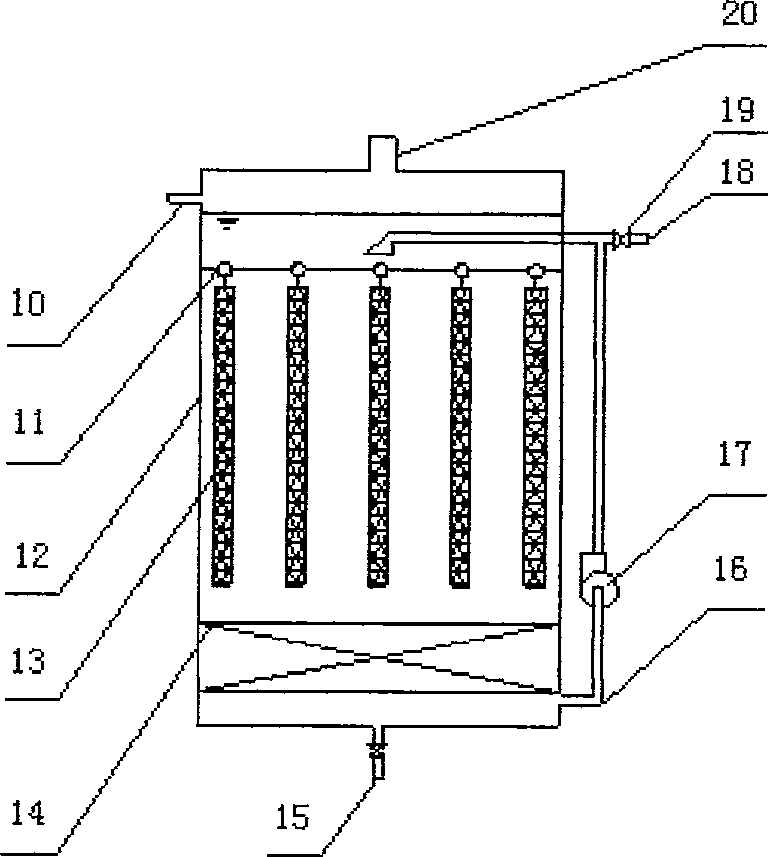

[0028] see figure 1 , 2 and 3.

[0029] The amount of concentrated sludge in a sewage treatment plant with a sludge dry solid production of 20t / d is about 400m 3 / d (moisture content 95%), the concentrated sludge first performs partition heat exchange in heat exchanger A with the secondary steam from the hollow paddle dryer passing through heat exchanger B, and the temperature is raised to 35 ° C ~ 40 ° C, Then enter the aeration hydrolysis digestion reactor to carry out hydrolysis digestion; the main body of the aeration hydrolysis digestion reactor is two concentric cylinders with different diameters, the outer cylinder 3 is a closed structure, the upper side is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com