Coal on-line analyse equipment based on laser induced spectral and nerve network technology

A technology of laser-induced spectroscopy and analysis equipment, applied in the field of automatic measurement, can solve the problems that the sampling system is difficult to adapt to different industrial environments, does not give the industrial analysis results of operators, and affects the normal use of equipment, so as to avoid the reduction of thermal efficiency, The effect of stable measurement results and avoidance of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be further described below with reference to the drawings and embodiments, but the embodiments of the present invention are not limited thereto.

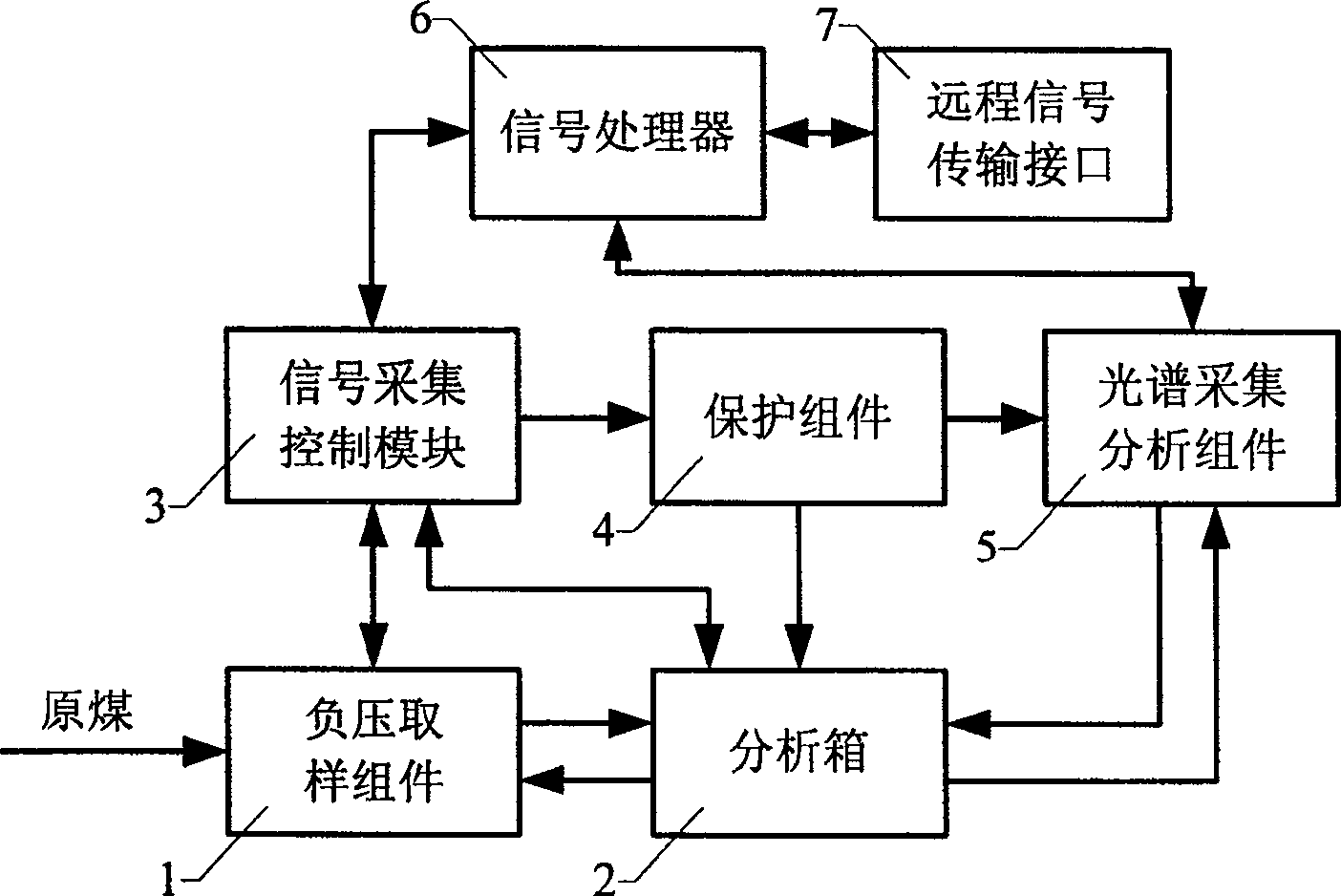

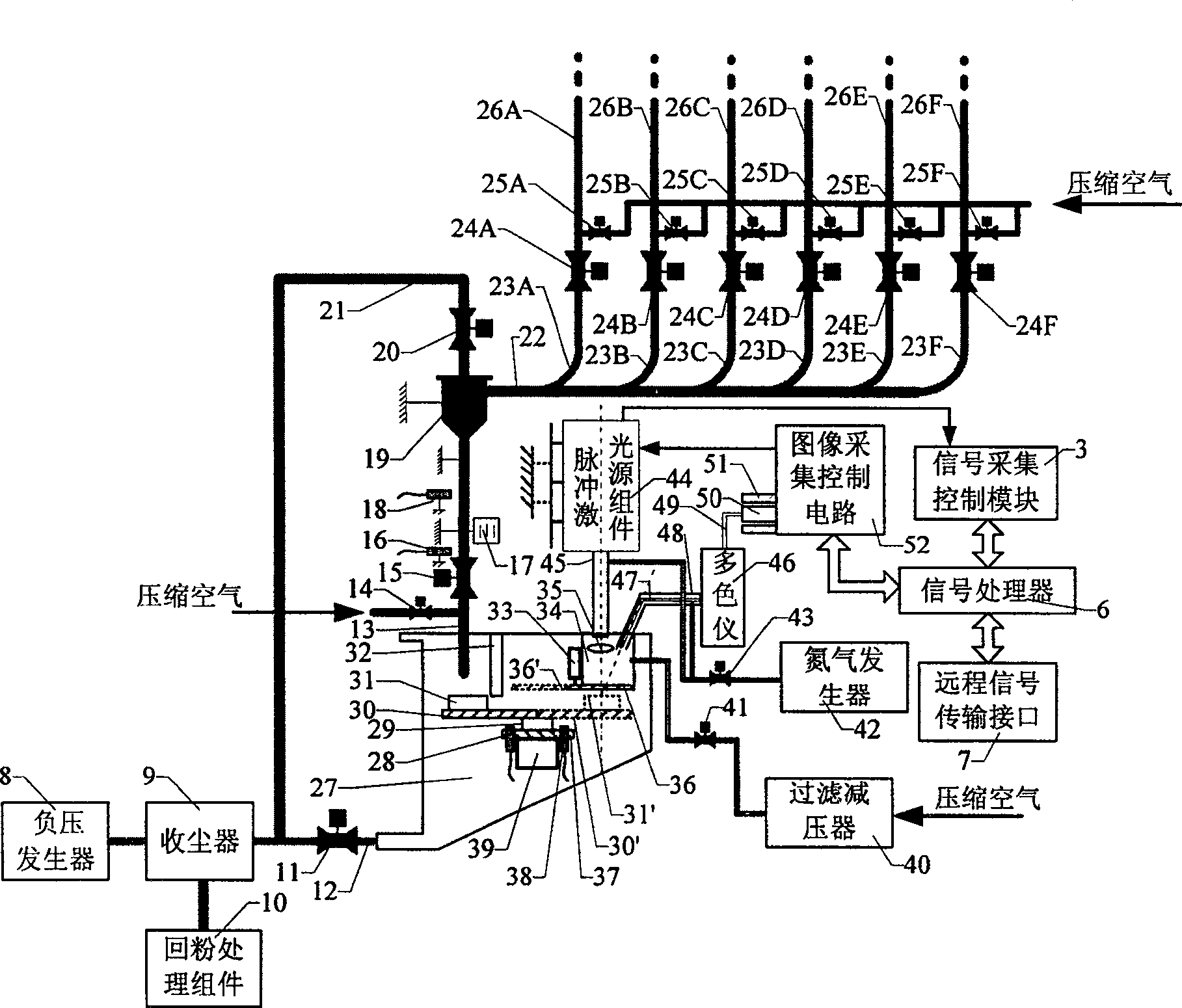

[0080] as attached figure 1 As shown, a coal quality online detection and analysis device of the present invention includes a negative pressure sampling component 1, an analysis box 2, a signal acquisition control module 3, a protection component 4, a spectrum acquisition and analysis component 5, a remote signal transmission interface 7 and a manual based Signal processors for neural networks6.

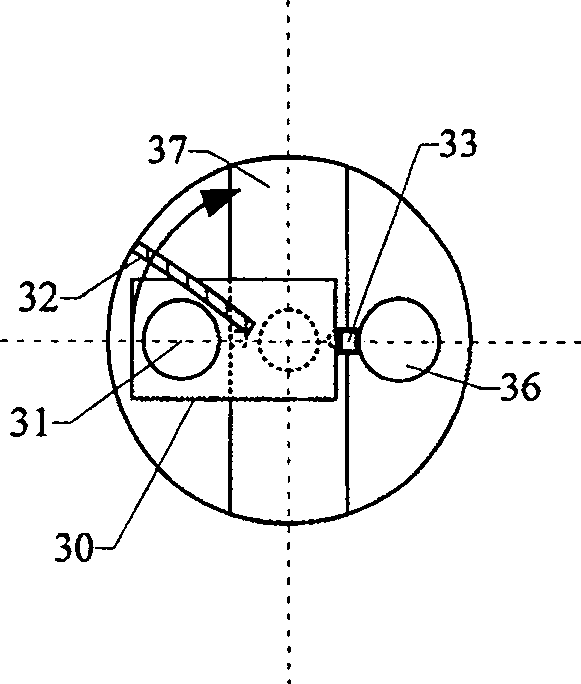

[0081] Negative pressure sampling assembly 1 includes negative pressure generator 8, dust collector 9, powder return processing assembly 10, powder discharge valve 11, purge valve 14, powder discharge valve 15, vibrator 17, lower powder level measurement sensor 16, upper Powder level measurement sensor 18, cyclone powder collector 19, negative pressure control valve 20, air extraction pipeline 21, samplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com