Process of extracting separating and purifying artemisinin from sweet wormwood herb

A technology for separation and purification of artemisinin, applied in the fields of plant/algae/fungus/moss components, plant raw materials, medical preparations containing active ingredients, etc., which can solve the problems of large solvent consumption, high extraction pressure, and long process time. , to achieve the effect of easy industrial scale, high output-price ratio and low extraction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

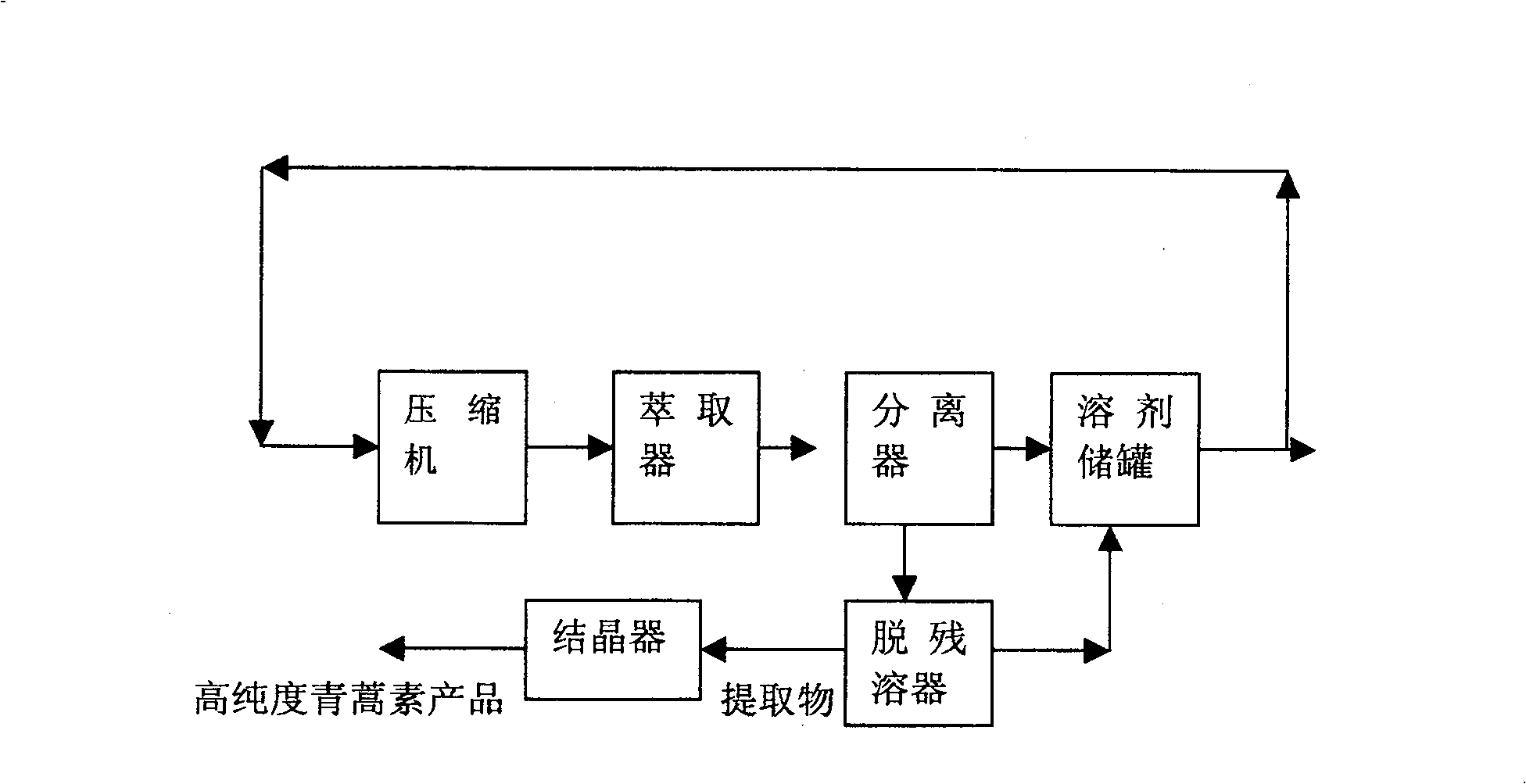

Image

Examples

Embodiment 1

[0015] according to figure 1 The procedure is to weigh 1 kg of Artemisia annua raw material crushed to 40 mesh and with an artemisinin content of 0.6%, put it into a 5-liter extractor, and then inject butane into the extractor through a compressor, and set the extraction temperature and pressure respectively to Set at 25°C and 0.4Mpa; after stirring and extracting for 0.5 hours, the solvent (extract) containing the solute is transferred to the separator, and the solvent butane comes out of the separator and enters the solvent storage tank for the next cycle. The solute (extract) coming out from the separator enters the desolventizer, and obtains 31.0 grams of artemisinin extract after further desolventization. Then add 465 milliliters of 40% ethanol solution at a weight-to-volume ratio of 1:15, heat to dissolve at 60°C, heat filter to remove insoluble matter, then place the filtrate at room temperature, filter after needle-like crystals are precipitated, and filter to obtain ...

Embodiment 2

[0017] Weigh 1 kg of raw material of Artemisia annua crushed to 40 mesh and with an artemisinin content of 0.6%, put it into a 5-liter extractor, then inject butane into the extractor, and set the extraction temperature and pressure to 45°C and 0.6Mpa; after stirring and extracting for 1.0 hour, the extract (solvent + solute) is transferred to the separator, and the solvent butane comes out of the separator and enters the solvent storage tank for the next cycle. The extract that comes out from the separator enters the desolventizer, and obtains 34.0 grams of extract after further desolvation. Then add 340 ml of 55% ethanol solution at a weight-to-volume ratio of 1:10, heat to dissolve at 60°C, heat filter to remove insoluble matter, then place the filtrate at room temperature, and filter after needle-like crystals are precipitated. The obtained crystals were dissolved in absolute ethanol and then purified by recrystallization. The weight-to-volume ratio of crystals to absolute...

Embodiment 3

[0019] Weigh 1 kg of raw materials of Artemisia annua crushed to 40 mesh and with an artemisinin content of 0.6%, put it into a 5-liter extractor, then inject butane into the extractor, and set the extraction temperature and pressure to 65°C and 65°C respectively. 1.0Mpa; after stirring and extracting for 3.0 hours, the extract (solvent + solute) is transferred to the separator, and the solvent butane comes out of the separator and enters the solvent storage tank for the next cycle. The extract that comes out from the separator enters the desolventizer, and obtains 35.0 grams of extract after further desolvation. Then add 245 ml of 75% ethanol solution at a weight-to-volume ratio of 1:7, heat to dissolve at 60°C, heat filter to remove insoluble matter, then place the filtrate at room temperature, and filter after needle-like crystals are precipitated. The obtained crystals were dissolved in absolute ethanol and then purified by recrystallization. The weight-to-volume ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com