Tamping forming apparatus

A molding device and tamping hammer technology, applied to ceramic molding machines, manufacturing tools, etc., can solve problems such as difficulty in improving product quality and production efficiency, unsuitable for large-diameter container production, and difficulty in improving internal quality, so as to overcome product faults , beautiful appearance, reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

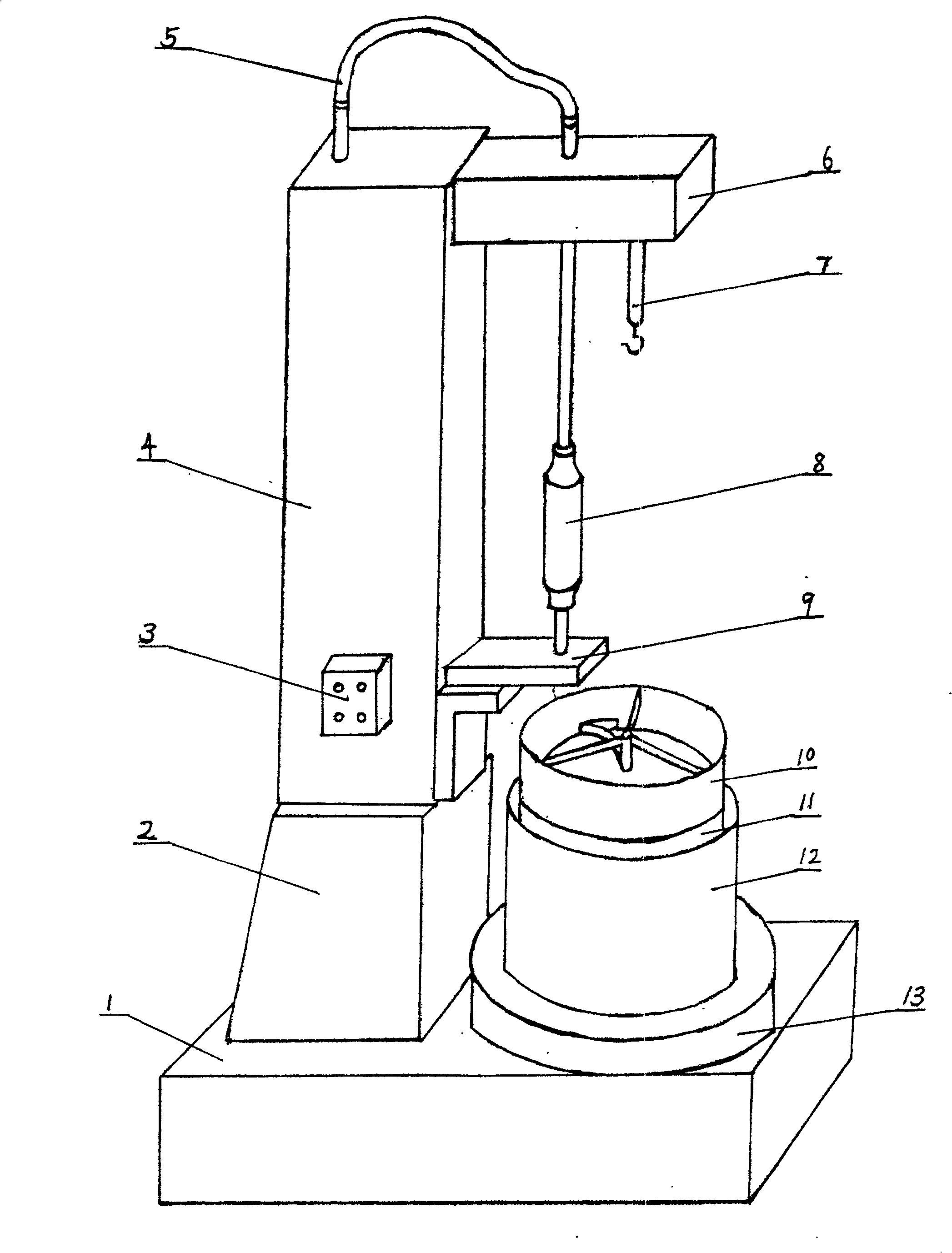

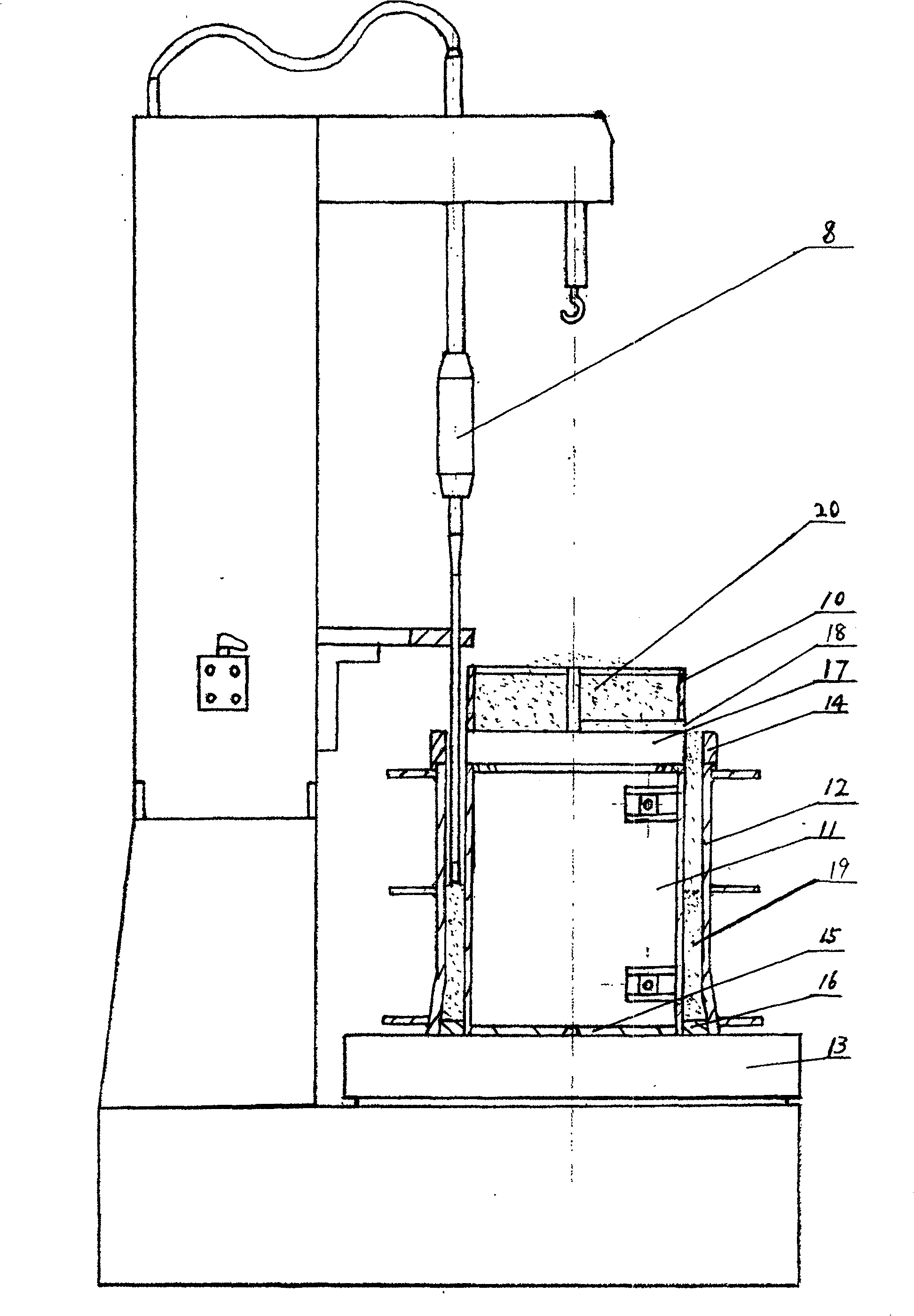

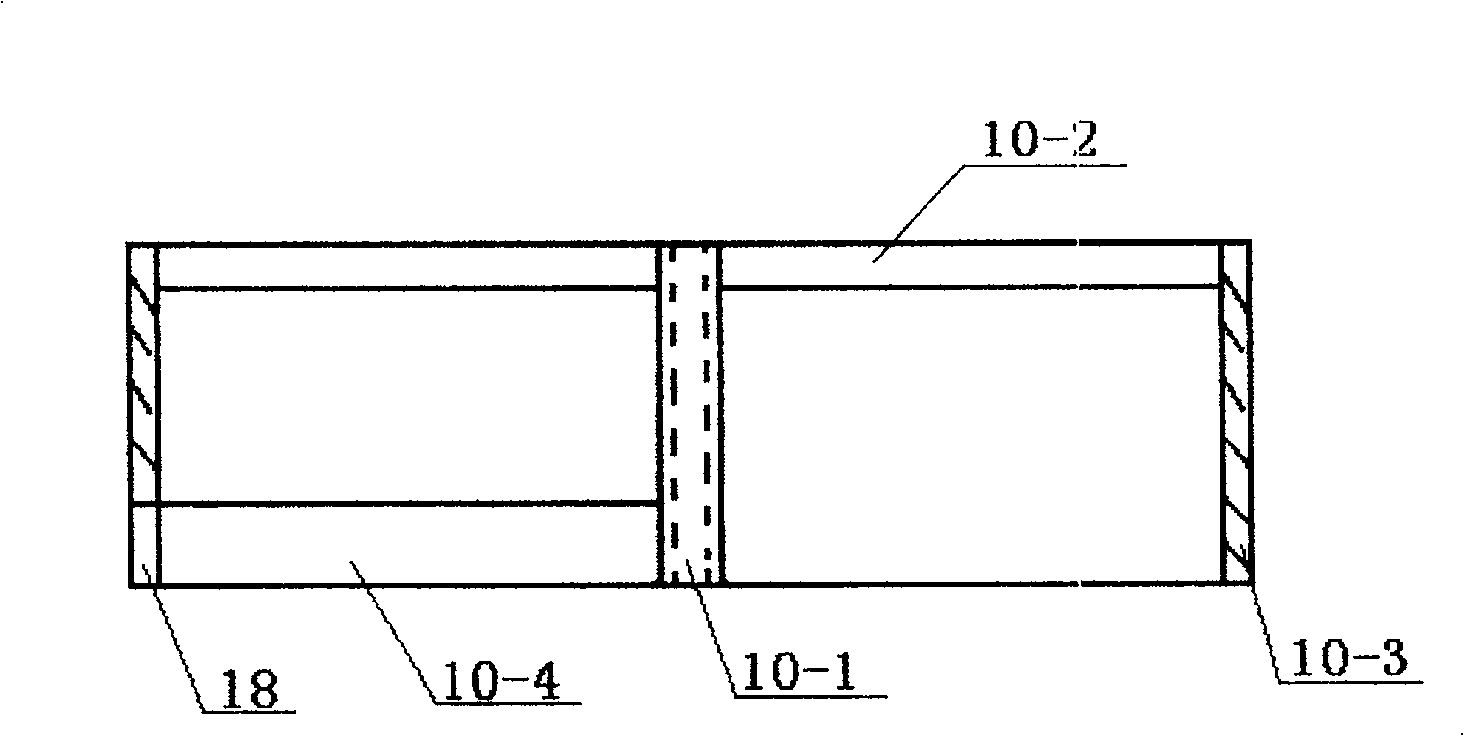

[0019] figure 1 , 2 As shown, the present invention includes a base 1, a power box 2, an electric control system 3, a column 4, a hose 5, a beam 6, a mold core lifting mechanism 7, a tamping hammer 8, a slide 9, a distributor 10, and an elastic mold core 11. Mould sleeve 12, rotating worktable 13; chassis 15 is bolted to the rotating worktable 13 as a part of the worktable; the electric control system 3 is located on the column 4 and electrically connected to the electrical components in the column 4; base 1, The power box 2, the column 4, the beam 6, the mold core lifting mechanism 7, the sliding slide 9, the rotating table 13, and the chassis 15 are connected as a whole as a whole supporting system.

[0020] The lower end of the tamping hammer 8 passes through a slide 9 with one end fixed on the column 4, corresponding to the product 19, and the upper end of the tamping hammer 8 passes through a beam 6 fixed at the upper end of the column 4 at one end and communicates with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com