Optoelectronic component packaging structure having silicon substrates

A technology for optoelectronic components and packaging structures, applied in electrical components, electrical solid-state devices, circuits, etc., can solve problems such as difficulty in mass production, affecting the wavelength of the emission light source, and complex processes, and achieve the effect of simplifying the complexity of components and increasing optical effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

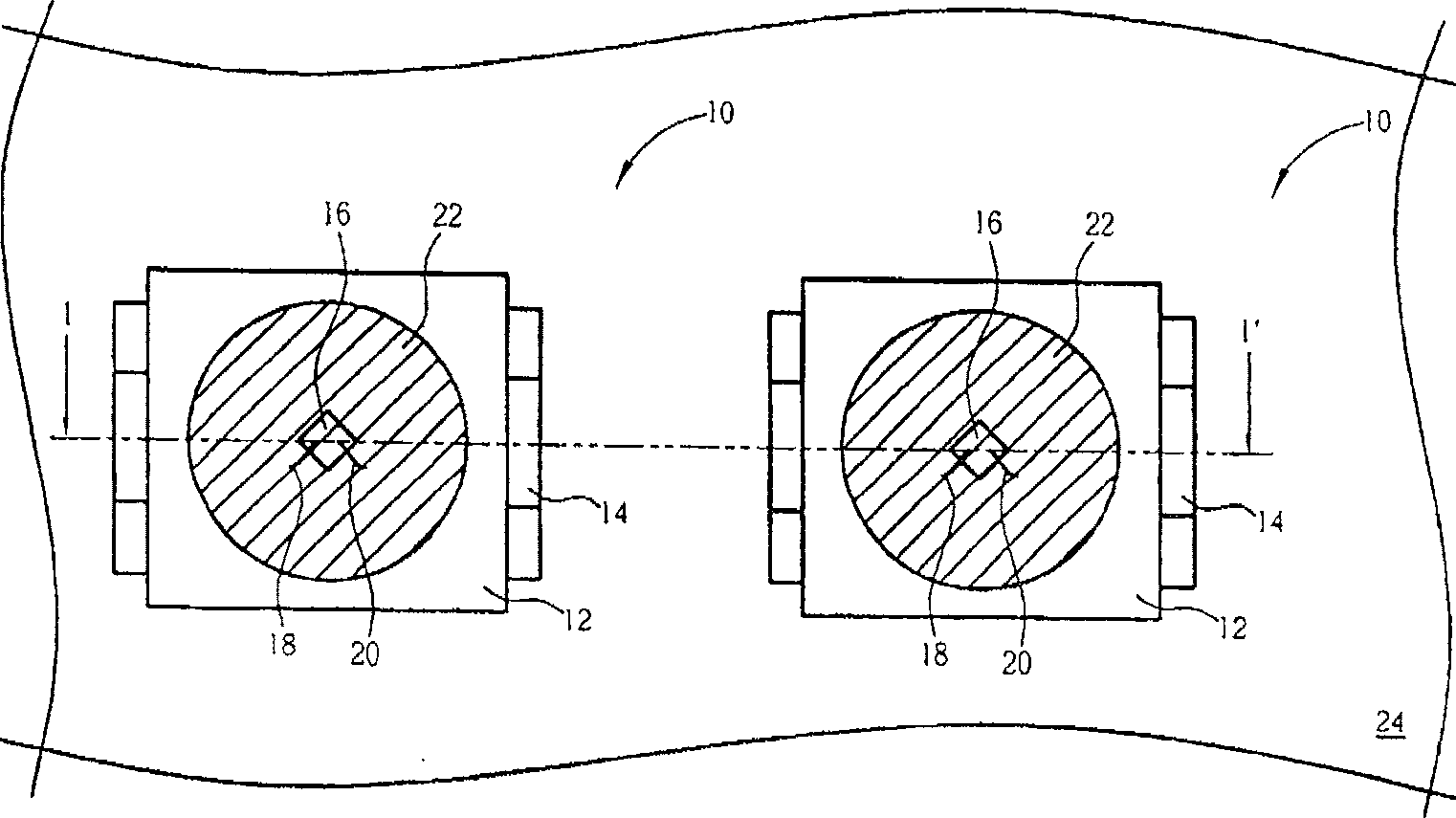

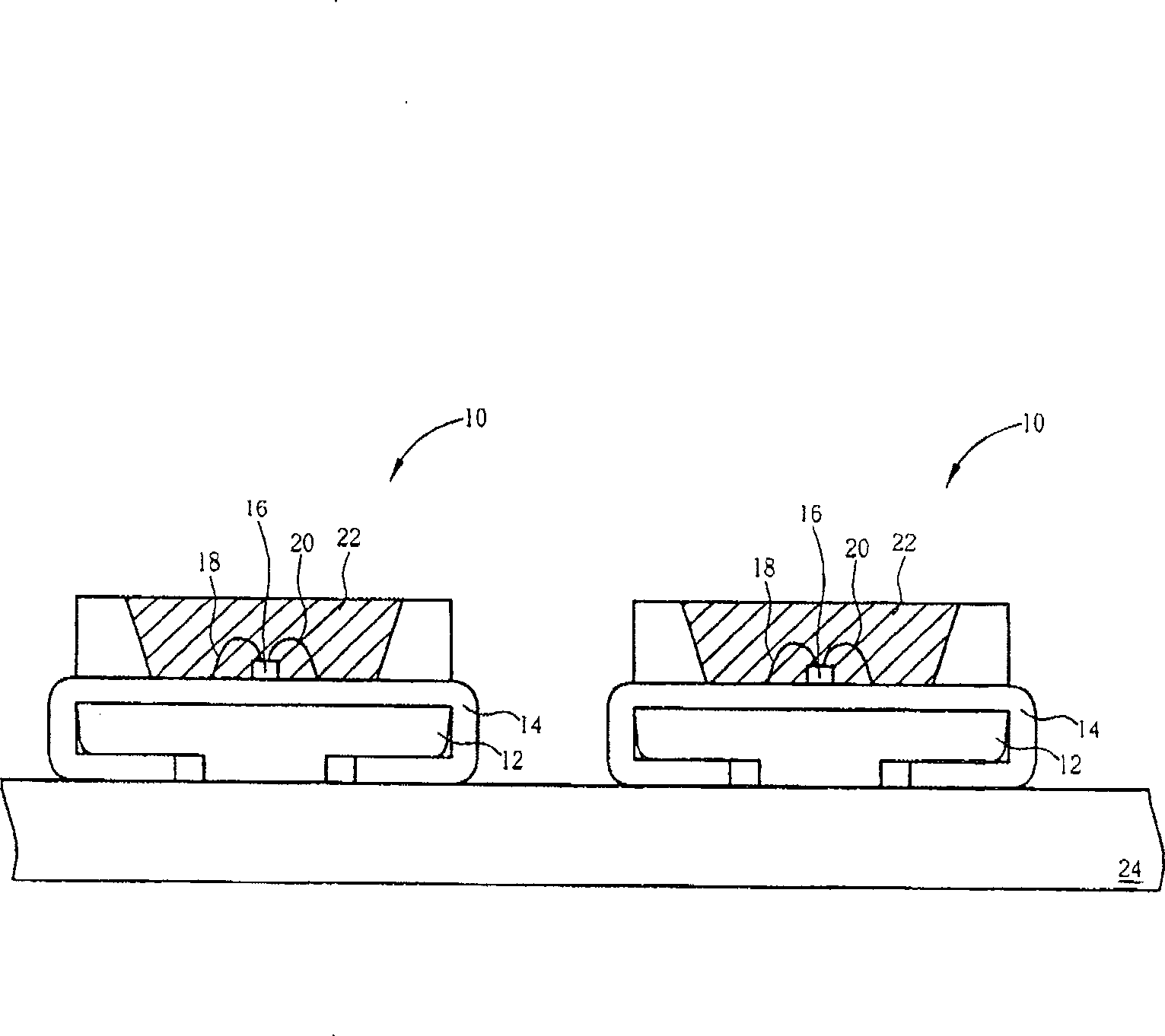

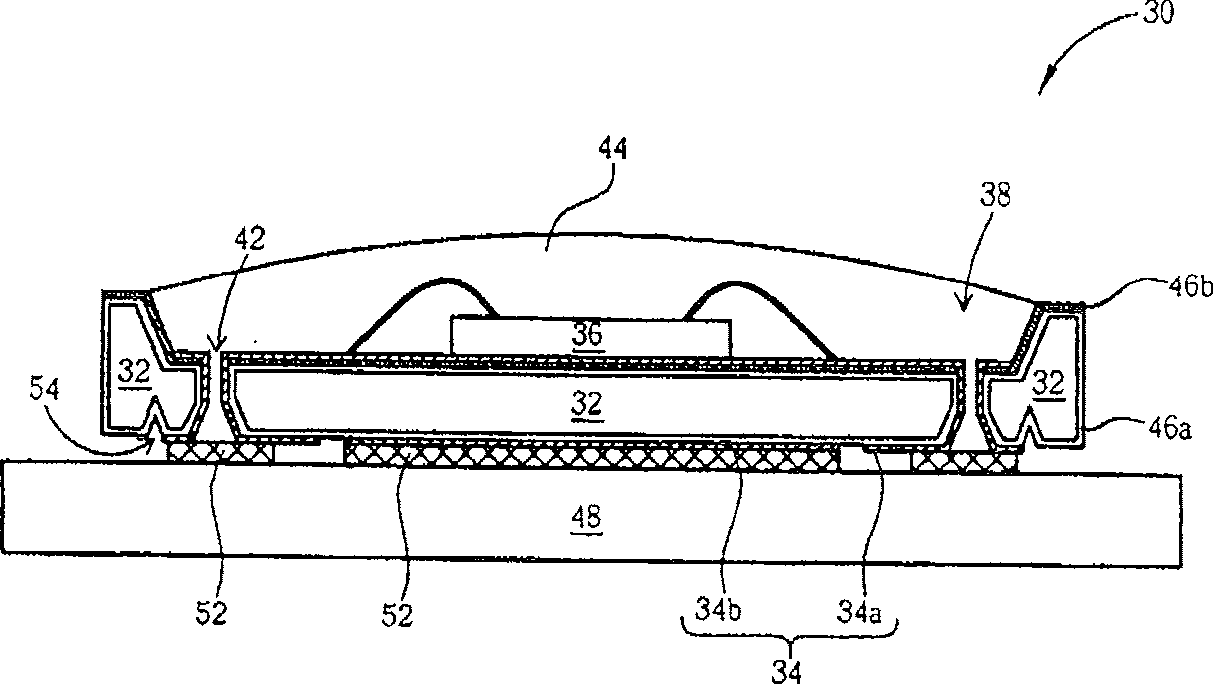

[0065] Please refer to image 3 and Figure 4 , image 3 is a schematic cross-sectional view of a photoelectric element packaging structure with a silicon substrate according to the first preferred embodiment of the present invention, and Figure 4 for image 3 The schematic top view of the package structure of the optoelectronic element shown. It should be noted that the drawings are for illustration purposes only and are not drawn to original scale. Such as image 3 and Figure 4 As shown, the photoelectric device packaging structure 30 includes a silicon substrate 32 , a plurality of guiding wires 34 and at least one photoelectric device 36 . The material of the silicon substrate 32 includes polysilicon, amorphous silicon or single crystal silicon, can be a square silicon chip or a circular silicon chip, and can contain integrated circuits or passive components therein. The silicon substrate 32 has an upper surface and a lower surface, and a concave cup structure 38 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com