First grade metallurgical coke produced from ordinary coking coal and its production method

A technology of raw material composition and coking coal, applied in coking ovens, petroleum industry, etc., can solve the problems of insufficient resources and high cost of primary coke, and achieve the effect of improving crushing strength and strength index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

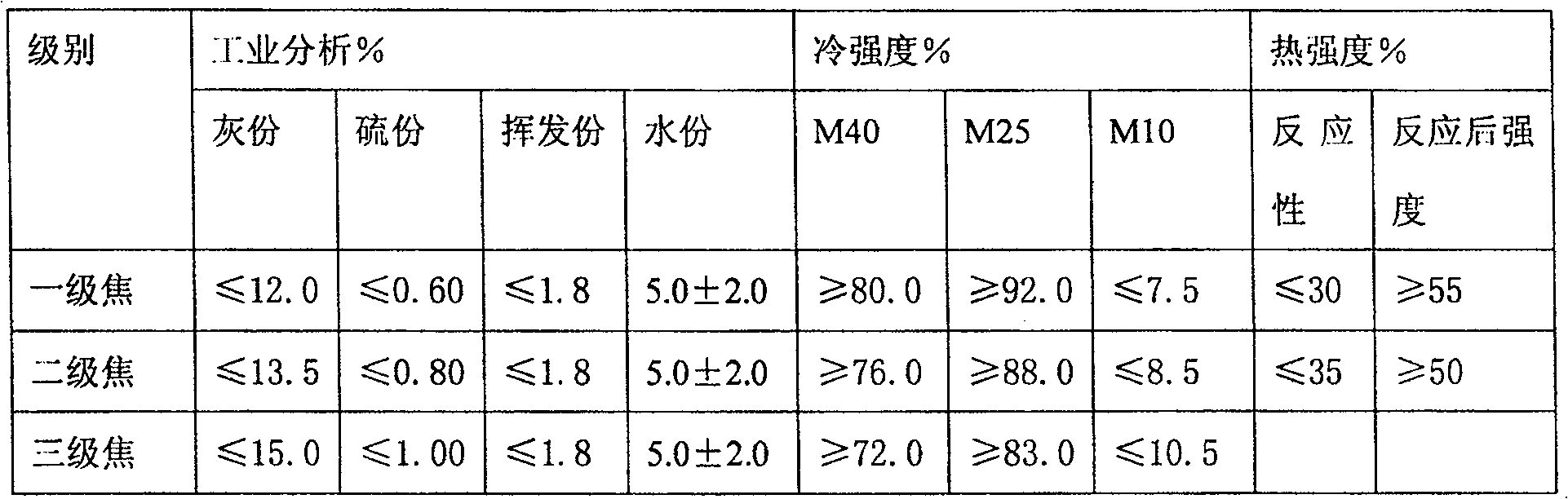

Image

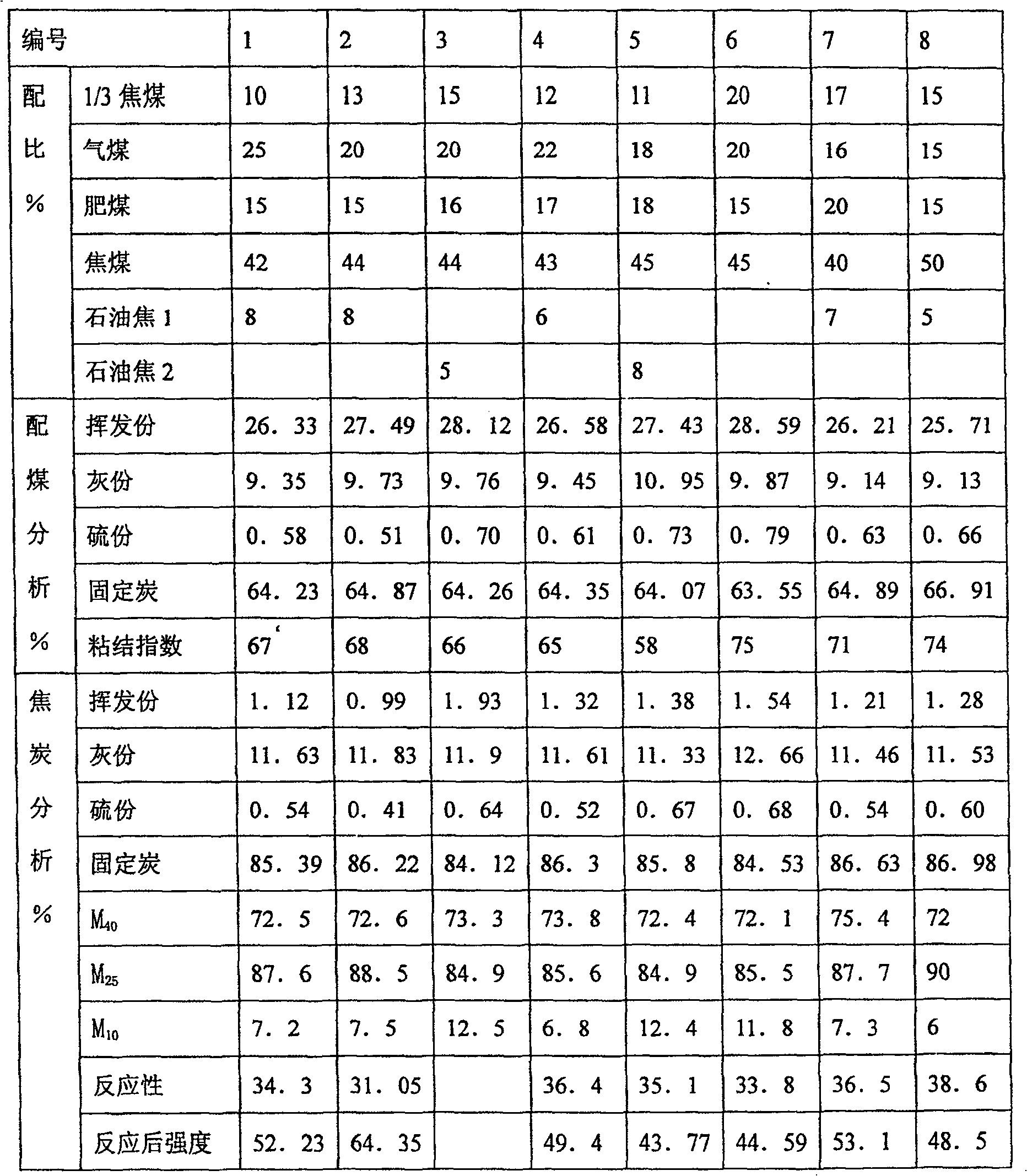

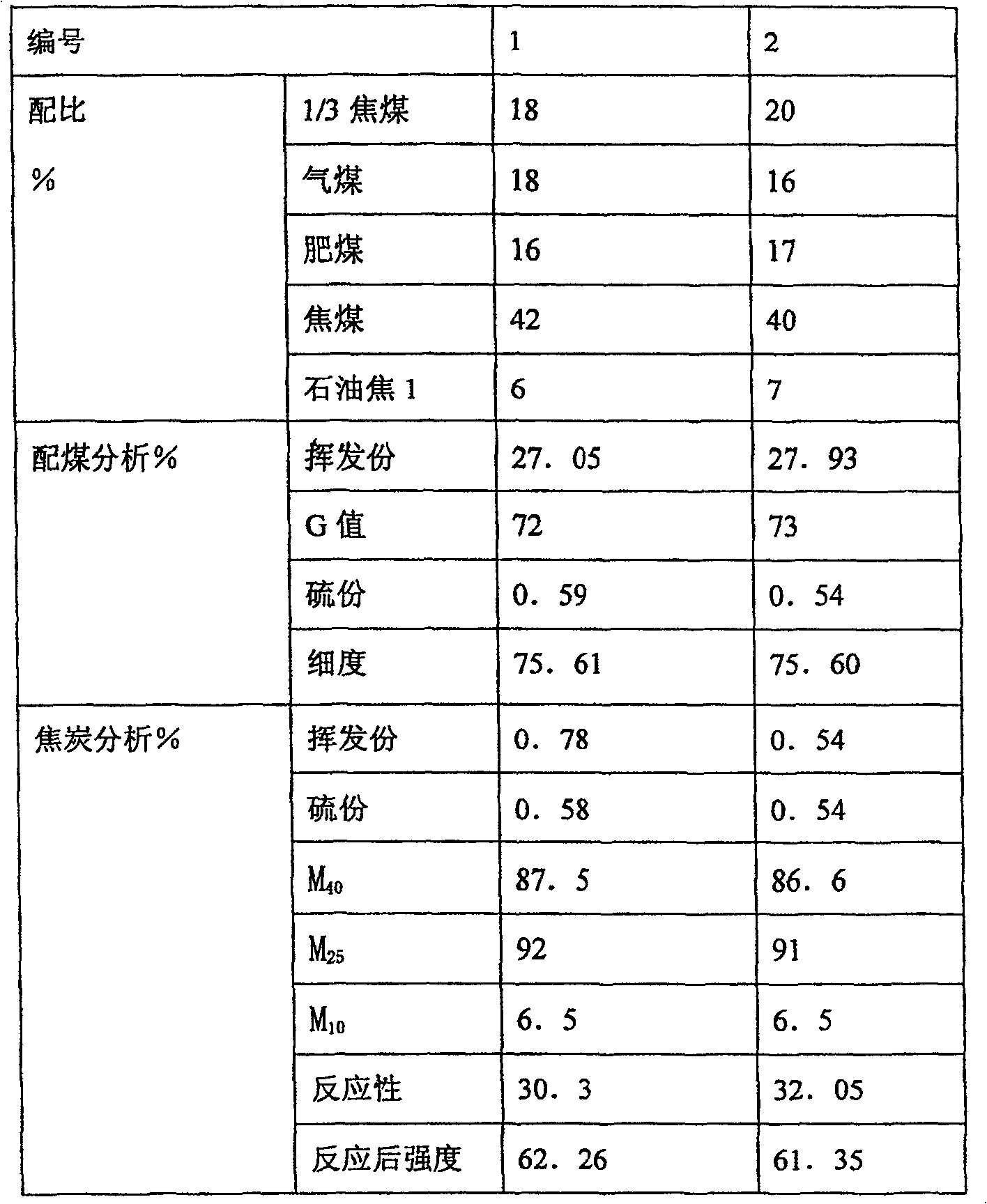

Examples

Embodiment Construction

[0015] Embodiment and comparative example are carried out in the test coke oven of 20 kilograms, and the carbonization chamber width of test coke oven is 200mm, and effective height is 400mm, and the effective volume of carbonization chamber is 0.032 cubic meter, and test coke oven adopts silicon molybdenum rod electric heating, The temperature is controlled by a single-chip microcomputer, and the top of the furnace is directly charged with coal. The main operating indicators of the mature coke oven are as follows:

[0016] Furnace coal weight: 23 kg

[0017] Furnace coal moisture content: 10±1%

[0018] Furnace coal crushing particle size: ≤3mm part accounts for more than 75% of the total

[0019] Coke cake center temperature: >950°C; combustion chamber temperature: 1060°C

[0020] Coking time: 8 hours

[0021] The coke discharged from the test coke oven was subjected to wet coke quenching with water, and after the coke was dried, it was dropped twice, and then the coke si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com