Powder metallurgy passenger car chain pulley and method for producing the same

A technology of powder metallurgy and sprockets, which is applied in the direction of belts/chains/gears, mechanical equipment, portable lifting devices, etc., can solve the problems of affecting the service life of car sprockets, affecting service life, and high production costs, and achieves easy installation and overall Good performance and light specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

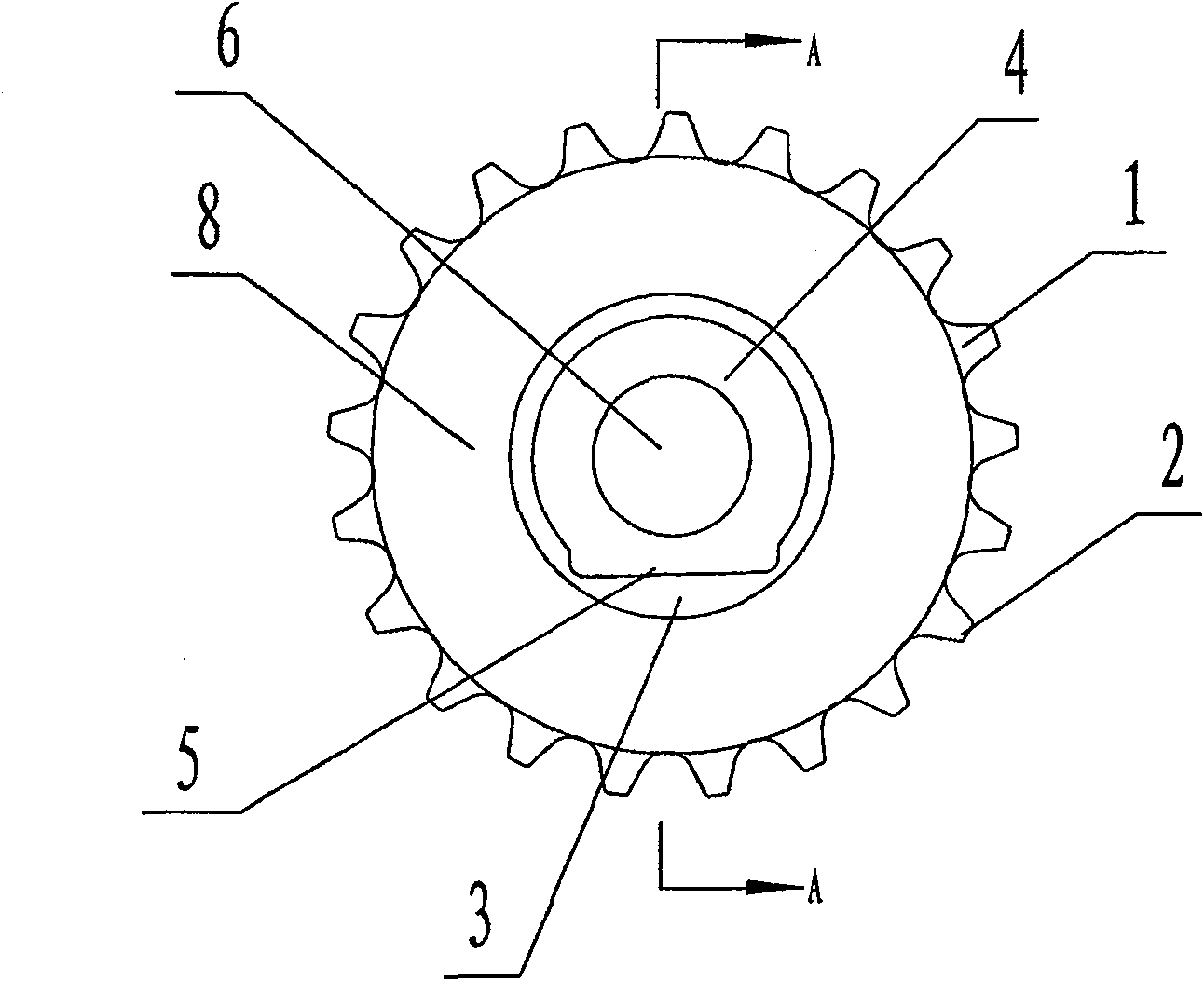

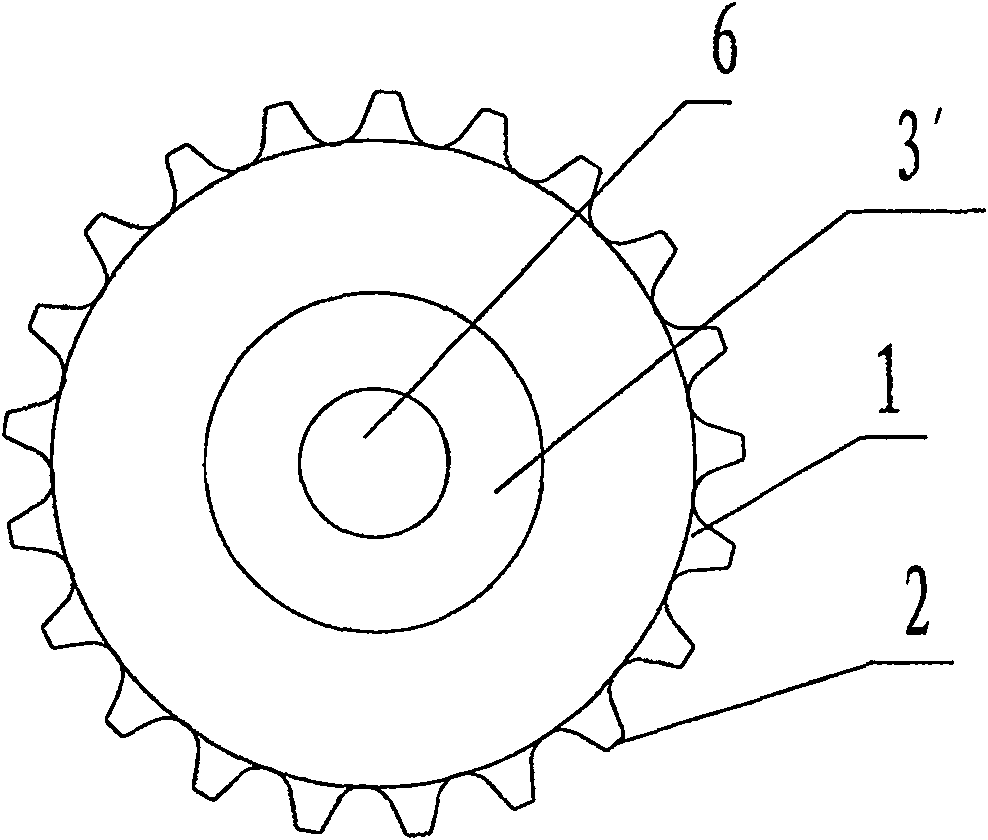

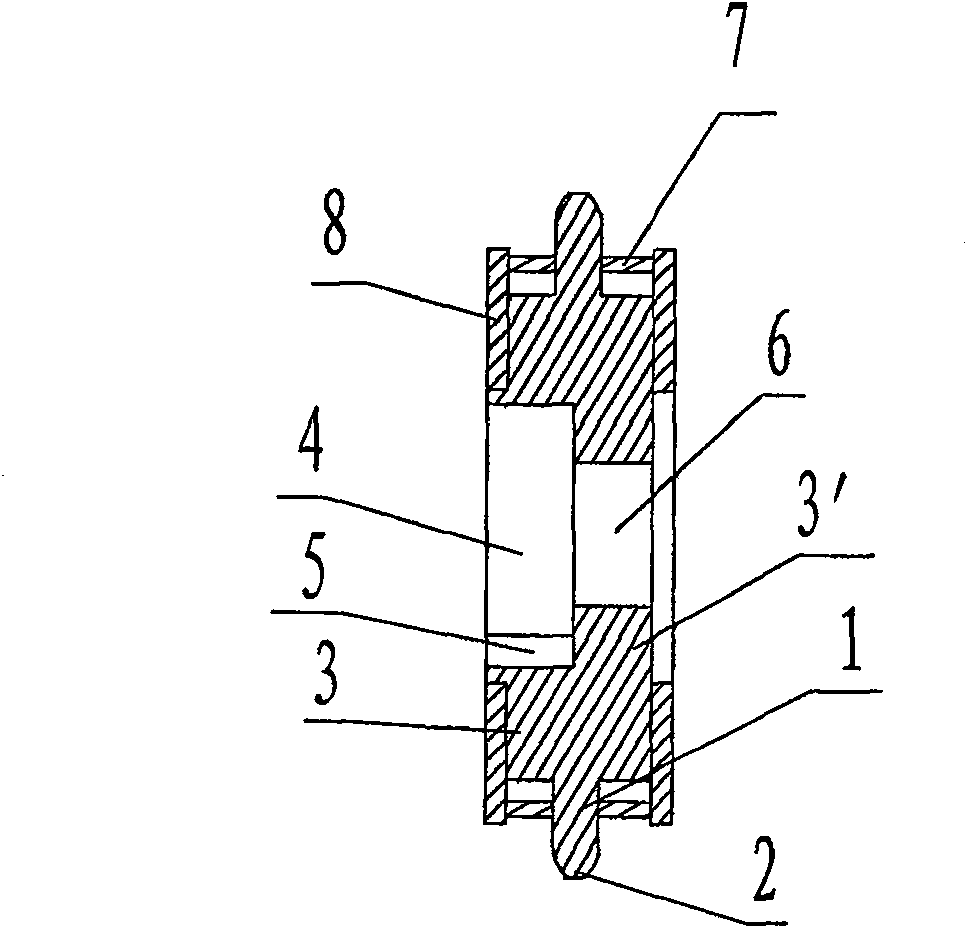

[0032] According to attached figure 1 , 2 , 3, 4, 5 produce powder metallurgy car sprockets, the production steps are as follows:

[0033] (1) Selection of ingredients and raw materials:

[0034] The sprocket body and teeth are made of powder metallurgy raw materials, and the weight percentage ratio of each raw material is: copper powder accounts for 3%, nickel powder accounts for 2%, graphite powder accounts for 0.6%, molybdenum powder accounts for 1.5%, iron powder accounts for 92.9%; The oil ring 7 is made of GCr15 steel; the sealing ring 8 is made of high-quality carbon steel sheet;

[0035] (2) Powder mixing:

[0036] The copper powder, nickel powder, graphite powder, molybdenum powder, and iron powder weighed according to the above weight ratio are mixed evenly with a double-cone mixer. Powder;

[0037] (3) Repression:

[0038] The powder metallurgical mixed powder for pressing the gear body and teeth is put into the die according to the sprocket style of the car a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com