Roboticized intelligent fixture system

A robot and tooling technology, applied in the field of manufacturing engineering, can solve the problems that combined tooling is difficult to meet the high-efficiency and high-precision machining, design, manufacturing, driving, and control of aircraft thin-walled curved surface parts, and it is difficult to meet the actual needs of aerospace vehicles. Achieve the effects of simplified daily maintenance, strong scalability, and reduced application costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

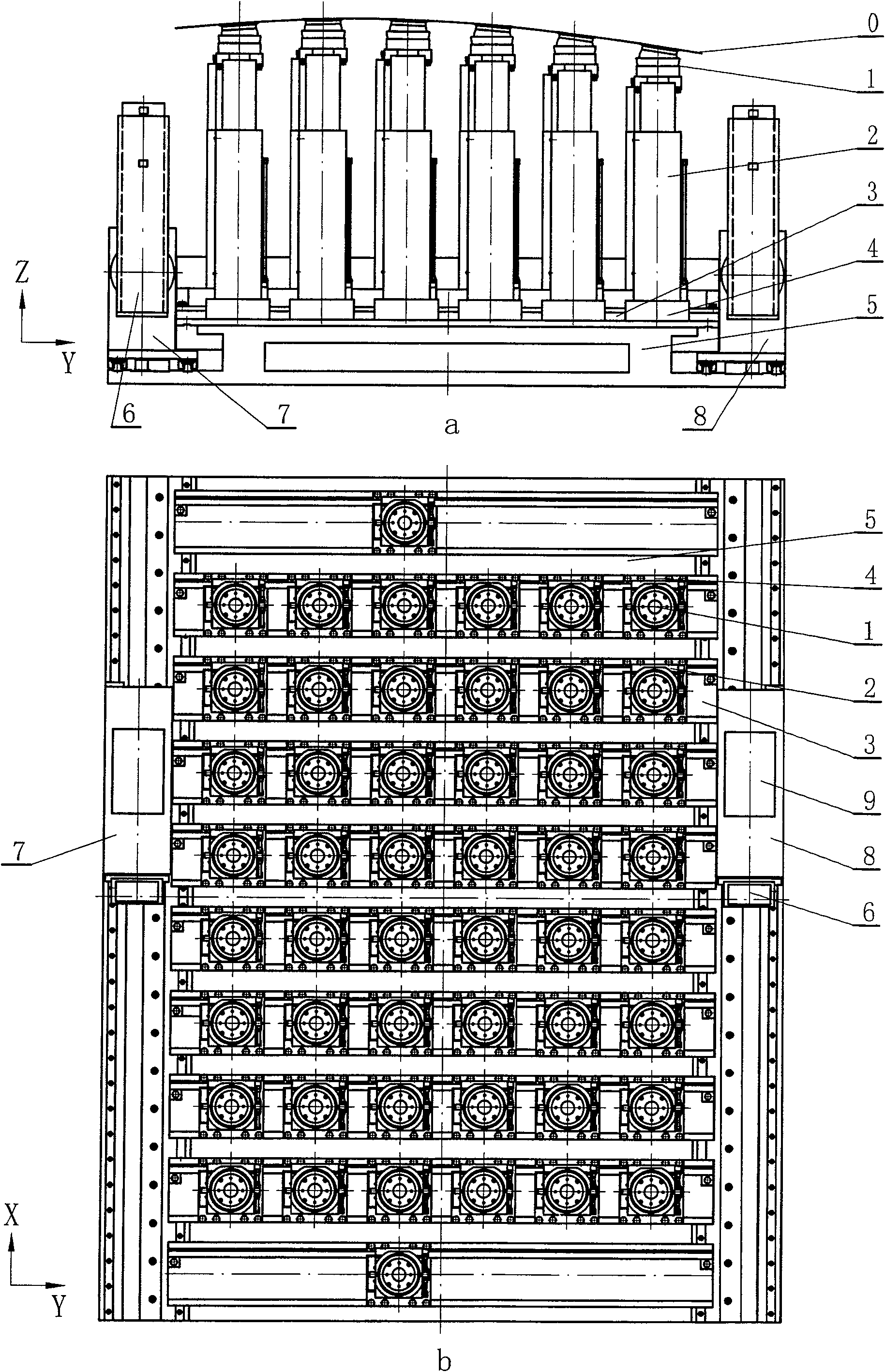

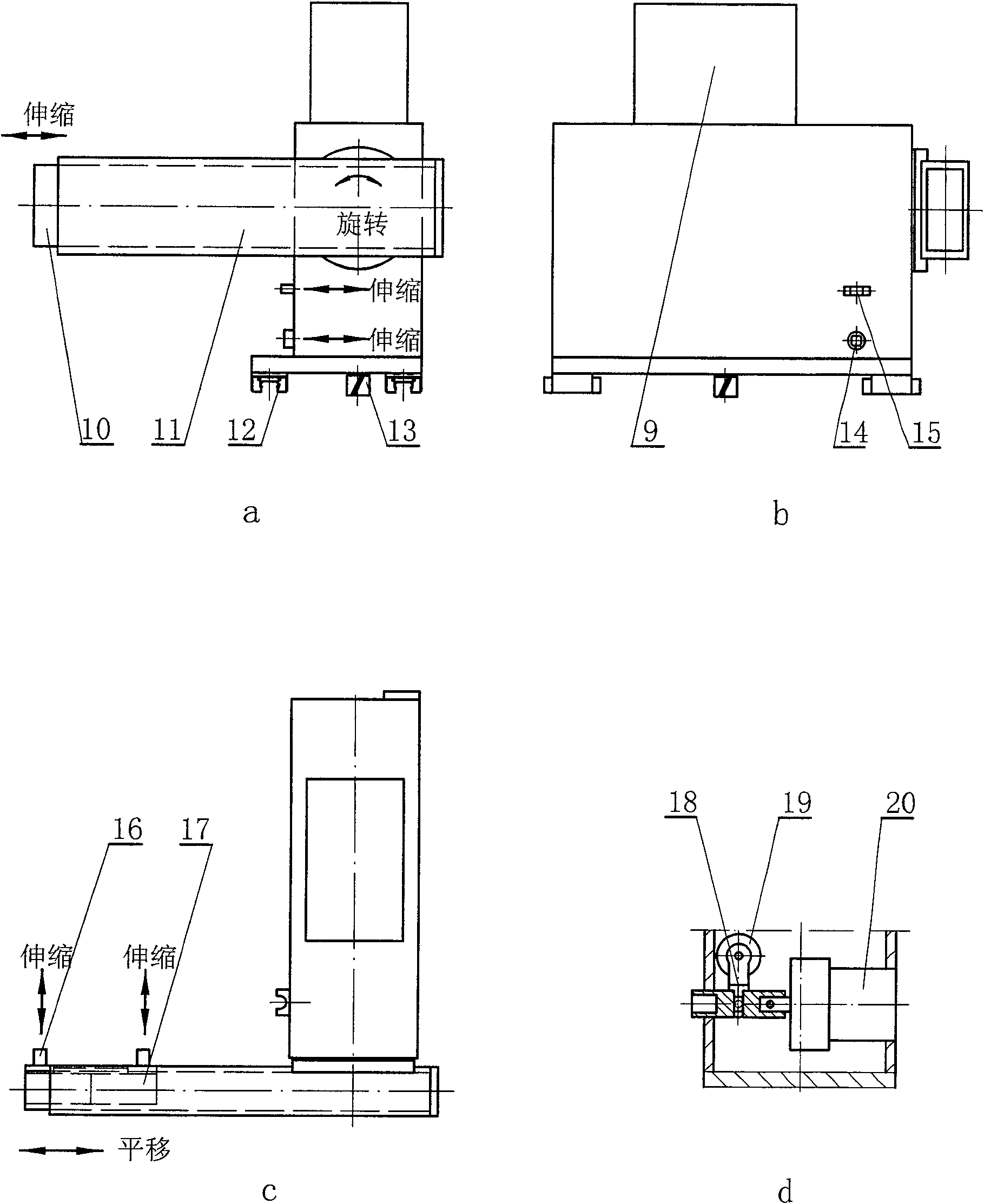

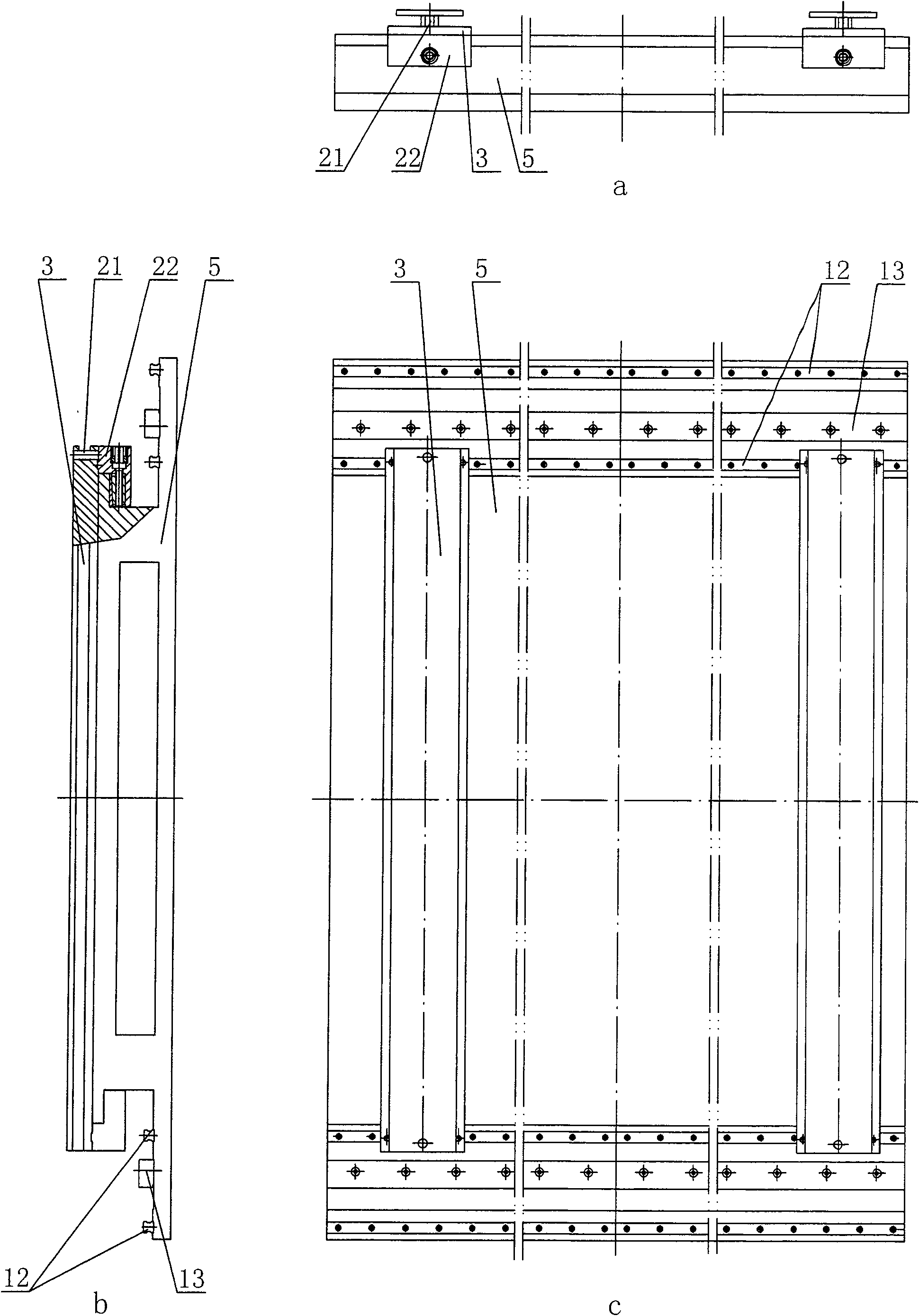

[0031] In order to achieve the above purpose, the invention figure 1 The robotized intelligent tooling system (hereinafter referred to as the tooling system) is shown. The system controls the coordinated movement of the dual robots through a computer to realize the intelligent operation of the tooling system. The whole system includes a base part 5, a moving beam part 3, a saddle part 4, a telescopic unit 2, a universal vacuum suction head 1, a left robot 7, a right robot 8, a control computer 9 and other components. It is characterized in that: the base part 5 is equipped with a plurality of moving beam parts 3, and each moving beam part moves along the X coordinate; the moving beam part is equipped with a plurality of sliding saddle parts 4, and each sliding saddle part moves along the Y coordinate; A telescopic unit 2 is installed on the saddle part, and the telescopic unit drives the universal vacuum suction head 1 at its top to move along the Z coordinate. Wherein, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com