Transparent acrylic ester impact-resisting modifier for PVC

A technology of acrylate and impact modifiers, which is applied in the field of transparent acrylate impact modifiers, and can solve the problems of poor weather resistance, inability to use outdoors, and inability to use polyvinyl chloride, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

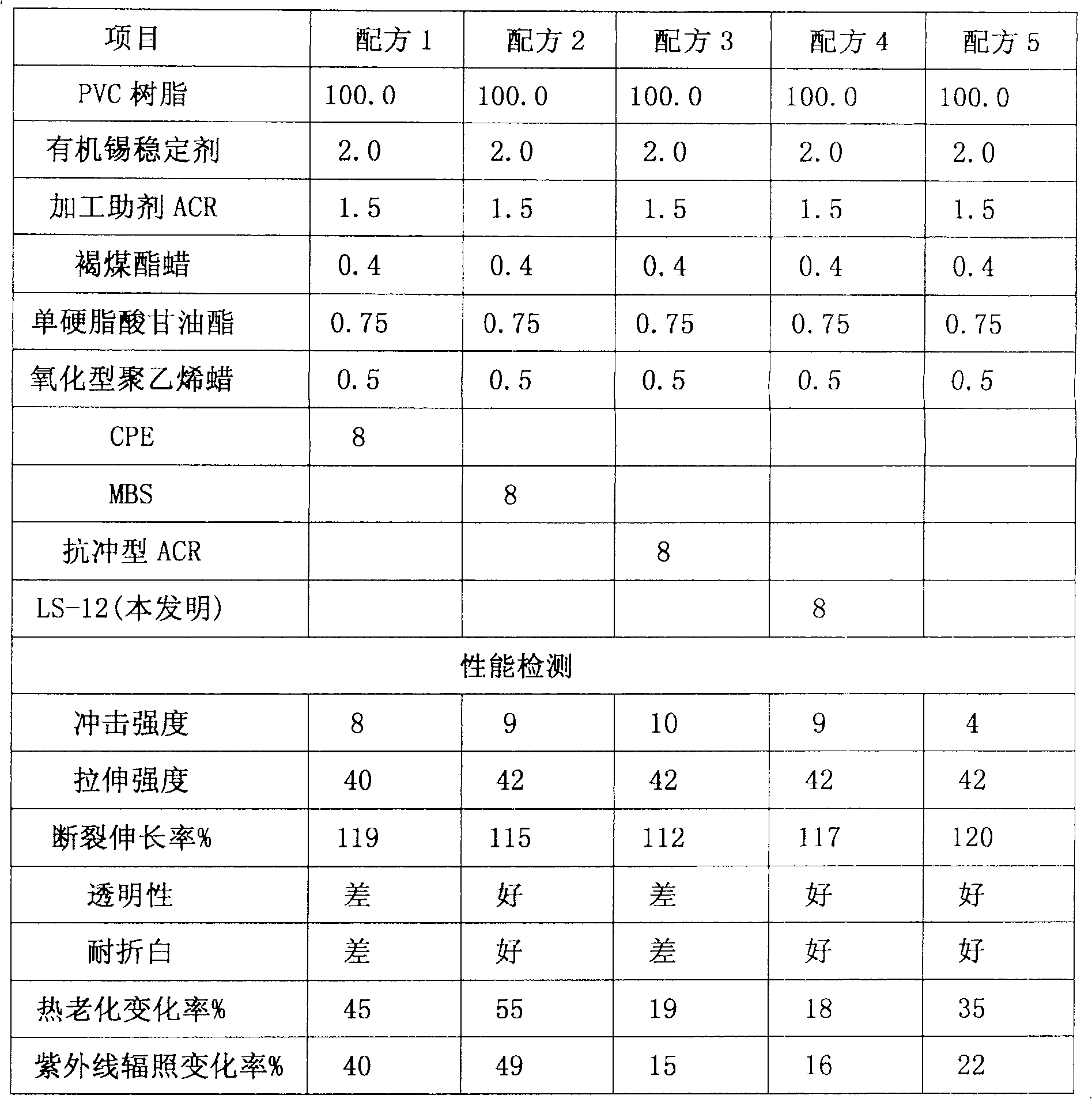

Examples

Embodiment 1

[0021] Add 50-70% soft water (the total amount of the emulsion is calculated as 100%), 1% (accounting for the total amount of polymerized monomers) sodium lauryl sulfate into a 3000L glass-lined kettle, start stirring, add butyl acrylate, benzene Ethylene and crosslinking agent ethylene glycol dimethacrylate, based on the amount of butyl acrylate and styrene as 100%, butyl acrylate is 50%, styrene is 50%, ethylene glycol dimethacrylate is 1% of the total amount of polymerized monomers in the core layer and 0.01% of the total amount of polymerized monomers in the core layer and the shell layer are added. ℃. After the exotherm is complete, keep the temperature at 80-85°C for 1 hour. Continue to add polymerized monomers methyl methacrylate and styrene to undergo emulsion polymerization grafting at 70-80 ° C to obtain a shell layer. Based on the total amount of polymerized monomers in the shell layer as 100%, methyl methacrylate is 50%. Styrene is 50%. The core layer polymerize...

Embodiment 2

[0023] The technical process is the same as in Example 1, except that the amount of sodium lauryl sulfate is 2% of the total polymerized monomers, the initiator adopts ammonium persulfate, and the consumption is 0.05% of the total polymerized monomers, and the crosslinking agent adopts Allyl methacrylate is used in an amount of 2% of the total amount of polymerized monomers in the core layer. The butyl acrylate in the core layer is 60%, the styrene is 40%, the methyl methacrylate in the shell layer is 40%, and the styrene is 60%. The monomer accounted for 10% of the total polymerized monomer. The pH of the emulsion was adjusted at 5 by acrylic acid.

Embodiment 3

[0025] The technical process is the same as in Example 1, except that the amount of sodium lauryl sulfate is 3% of the total polymerized monomer, the initiator adopts ammonium persulfate, and the consumption is 0.02% of the total polymerized monomer, and the crosslinking agent adopts The dosage of diallyl phthalate is 0.5% of the total amount of polymerized monomers in the core layer. The core layer is 70% butyl acrylate and 30% styrene. The methyl methacrylate in the shell layer is 50%, the styrene is 50%, the polymerized monomers in the core layer account for 80% of the total polymerized monomers, and the polymerized monomers in the shell layer account for 20% of the total polymerized monomers. Adjust the pH of the emulsion to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com