A reset compound Mg-Si-Sn base thermal electric material and its making method

A mg-si-sn, in-situ composite technology, applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problem that the second phase of the thermoelectric material is not very good, the distribution of the second phase is not good Determining and difficult to control the distribution of two phases, etc., to achieve the effect of reducing interface pollution, reducing thermal conductivity, and improving thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Raw materials are stoichiometrically compared to Mg 2 Si 0.5 sn 0.5 After calculation and weighing, put it in a ceramic tube protected by Ar gas, heat it in a furnace at 1100°C and fully melt it, then quickly move the ceramic tube to a furnace at 860°C, and then cool it to 780°C at a cooling rate of 1°C / min. Annealed at 600°C for 100h, then mechanically ball-milled the material, then hot-pressed in vacuum at 600°C and 80MPa for 2h. The in-situ composite Mg-Si-Sn based thermoelectric material is obtained.

[0020] RigakuD / MAX-2550PC X-ray polycrystalline diffractometer (XRD) was used to analyze the phase of the sample prepared in this example, and the sample was obtained as a composite material of Si-rich phase and Sn-rich phase.

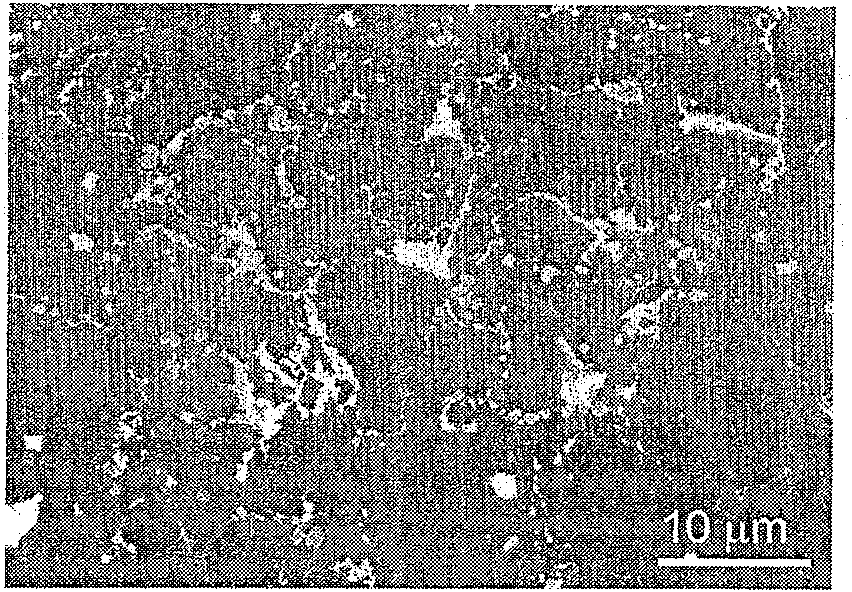

[0021] Using FEI Sirion Field Emission Scanning Electron Microscope (FESEM) to observe the microstructure of the material, such as figure 1 As shown, the surface of the sample is coated with a thin layer of 200nm. XRD and energy spectrum a...

Embodiment 2

[0024] Raw materials are stoichiometrically compared to Mg 1.992 La 0.008 Si 0.52 sn 0.48 After calculation and weighing, put it in a ceramic tube protected by Ar gas, heat it in a furnace at 1200°C and fully melt it, then quickly move the ceramic tube to a furnace at 900°C, and then cool it to 780°C at a cooling rate of 1°C / min. Annealed at 600°C for 150h, then mechanically ball-milled the material, and then vacuum hot-pressed at 600°C and 80MPa for 1h. Microstructure observation shows that the surface of the sample is covered with a 500nm thin layer. XRD and energy spectrum analysis show that the Si:Sn atomic content ratio of the Sn-rich phase is 0.35:0.65, and the Si-rich phase Si:Sn atomic content ratio is 0.7:0.3. The performance test shows that the thermal conductivity of the composite thermoelectric material is κ=1.9W·m at room temperature -1 K -1 , the Z value is 1000×10 at 800K -6 K -1 .

Embodiment 3

[0026] Raw materials are stoichiometrically compared to Mg 1.98 La 0.02 Si 0.55 sn 0.45 After calculation and weighing, put it in a ceramic tube protected by Ar gas, heat it in a furnace at 1150 °C and fully melt it, then quickly move the ceramic tube to a furnace at 900 °C, and then cool it to 780 °C at a cooling rate of 1 °C / min. Then anneal at 600°C for 100h, and then mechanically ball mill the material, then vacuum hot press at 700°C and 80MPa for 2h. Microstructure observation shows that the surface of the sample is covered with a 100nm thin layer. XRD and energy spectrum analysis show that the Si:Sn atomic content ratio of the Sn-rich phase is 0.4:0.6, and the Si-rich phase Si:Sn atomic content ratio is 0.7:0.3. The performance test shows that the thermal conductivity of the composite thermoelectric material is κ=2.0W·m at room temperature -1 K -1 , the Z value is 960×10 at 800K -6 K -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com